Foods such as powdered coffee and medical supplies like antibiotics are sensitive to heat, which makes their manufacturing quite demanding. In their viscous form, they are difficult to package and use; hence, they are often dried using advanced machinery, such as an agitated thin-film dryer.

Whether you work within or outside manufacturing facilities reliant on ATFD, this article takes you through the ins and outs of this specialized machine.

What is an Agitated Thin Film Dryer

An agitated thin film machine is a distinct machine that converts liquids and viscous materials that are negatively impacted by heat into dry, more portable products without degrading their quality.

This drying system uses a heated cylindrical wall to dislodge the moisture in your viscous material. The machine facilitates rapid evaporation, which sees your slurry products dry before the heat starts degrading them.

Parts of an Agitated Thick Film Dryer

Getting rid of the moisture in heat-sensitive products such as medication, especially using heat, is no mean feat. Agitated thick film dryers thrive in drying such products, partly due to their unique composition, which includes parts such as;

| ATFD Component | Function |

| · Feed Inlet | This is an entry point that allows you to load your liquid or viscous products into the ATFD. |

| · Jacketed Cylinder | Provides the heating surface that dislodges the moisture from your products, drying them efficiently. |

| · Rotor Assembly | A simple shaft fitted with blades that spread your feed material, creating a thin film. |

| · Vapor Outlet | Provides an escape route for the vaporized moisture dislodged from the liquid products. |

| · Discharge Outlet | Found at the bottom of the machine, it provides an exit route for the dried goods. |

| · Vacuum System | Although it is optional, it helps regulate the processing temperature. |

| · Drive System | Handles the rotation of the internal rotor, leading to the formation of a thin film. It also facilitates the endless agitation needed to prevent scaling. |

How an Agitated Thin Film Dryer Works

Drying viscous material, such as pastes, to generate solid products may sound easy, but it is slightly harder than you would think. Agitated thin film drying gets rid of the moisture in heat-sensitive liquids or pastes without altering their integrity or quality. It follows the following steps;

- Wet Material Feeding:To begin with, the liquid or non-solid material is introduced to the ATFD through the infeed system, which typically sits at the top of your vertical machine or at the front end of horizontal ATFDs.

- Generation of a Thin Film:Once the feed material is introduced, it is subsequently spread over an inner surface with the aid of spinning blades. This thin film typically measures between 0.5 and 2 millimeters.

- Rapid Stirring:As the liquid or viscous material is spread into a thin film, the blades supported by the rotor assembly keep stirring the resulting thin film, ensuring that the heat is distributed evenly. This agitation also keeps the material from sticking to the heated surface.

- Speedy Evaporation:With the film spread out thinly across the heated surface, controlled heat is applied, prompting the rapid loss of moisture from the material via evaporation. The uniform distribution of the material into a thin layer, coupled with the continuous agitation by the blades, contributes to speedy evaporation, thus averting heat-related damage to your products.

- Extraction of the Resulting Vapor:The vapor derived from the moisture forced out of the feed material is consequently driven out of the agitated thin film dryer through a dedicated vapor outlet.

- Collection of the Dried Product:After all the moisture in the feed material has been extracted through evaporation, you are left with a dry product, which you can convey to the next production station or package in readiness for distribution.

ATFD Types

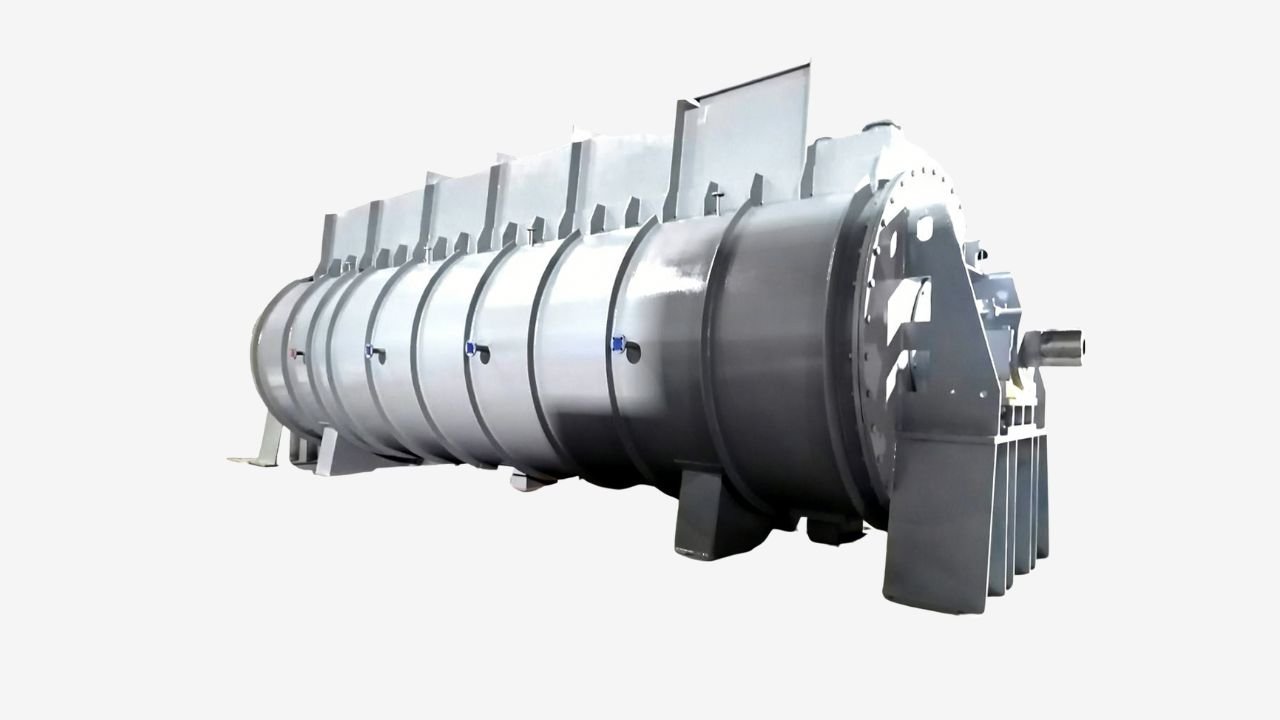

· Horizontal Agitated Thin Film Dryer

The horizontal ATFD is a unique drying machine comprised of a reclining jacketed cylinder that gets rid of solvents from your viscous materials, despite their sensitivity to heat. The feeding system is located on one end of the machine, particularly the front end.

This makes it ideal for drying fairly gentle products such as chemical intermediaries, pharmaceuticals, and synthetic resins. They also boast a relatively shorter residence time, as low as a couple of seconds, and they are perfect for challenging materials such as sludges and fouling materials.

· Vertical Agitated Thin Film Dryer

The vertical agitated thin film dryer thrives in drying crystallizing materials and highly sticky products thanks to its unique setup. Its infeed system lies at the top of the machine, meaning that you load your raw products from the top.

It boasts one of the shortest residence times, qualifying its use in drying products that are overly sensitive to heat. Modern vertical ATFDs come paired with condensation systems, which help you recover the moisture or solvent extracted to dry your products.

· Vacuum ATFD

Vacuum agitated thin film dryers are fitted with a vacuum system, which essentially helps bring down the boiling point of the solvents in your paste or sludge. This means that less heat is required to initiate evaporation, thus minimizing the risk of damaging heat-sensitive materials. As such, they are highly utilized in the production and packaging of chemical, pharmaceutical, and food products with greater heat sensitivity.

· Atmospheric Agitated Thin Film Dryer

This drying machine simply runs at ambient pressure, making it the perfect dryer for pastes that are likely to foul normal equipment and sludges that would otherwise burn when exposed to heat.

Most atmospheric agitated thin film dryers come with a vertical heated cylinder and a rotor assembly positioned centrally. Vapor drawn from the feed material is consequently released into the atmosphere. However, some come with condensers, allowing you to retrieve the lost moisture or solvent.

Agitated Thin Film Dryer Advantages

Despite the existence of other dryers, some of which are much older, agitated thin film drying machines have cemented their name as one of the best. They promise a number of rewards, which most of their competitors cannot match. These include:

- Shorter Residence Time:Most materials dried by ATFDs are only exposed to heat for a couple of seconds or a few minutes at most. This reduces the risk of your product’s quality deteriorating or the product getting burnt.

- Great Thermal Efficiency:Agitated thin film drying machines are up to 5 times more efficient than traditional dryers. This is because they spread the feed material into thin layers measuring 0.5mm to 2mm, thus reducing the residence time significantly.

- Energy Efficiency:By reducing the number of minutes or seconds the feed material is exposed to, ATFDs greatly reduce the amount of energy consumed to produce dried goods. This translates into lower energy bills.

- Reduced Thermal Stress:ATFDs only subject the viscous products to heat for a short time, meaning these products are less prone to damage resulting from excessive heat exposure. Furthermore, it safeguards the quality and integrity of your goods.

- Superior Temperature Control:The drying machine spreads the feed material quite thinly and agitates this thin layer continuously using specialized blades. This ensures that heat is distributed evenly, thus drying the product uniformly.

- Can Process Highly Viscous Materials:With an ATFD, there is virtually no limit to the feed material you can dry. Thanks to the machine’s superior temperature control and short residence time, you can dry pastes and sludges with viscosities hitting 50,000 centipoises.

- Reduced Product Buildup:The dryer comes with motor-controlled blades that keep agitating the thin film of your product during drying. This keeps it from sticking to the heated surface.

Common Uses of Agitated Thin Film Dryers

Unlike most other dryers, the agitated thin film drying machine handles products with varying heat sensitivities as well as viscosities flawlessly. As a result, these machines have penetrated virtually all industries, as manufacturers seek to improve the quality and quantity of dried goods produced. They are a common feature in

- Chemical Processing:Most chemicals are manufactured in liquid form and dried using ATFDs to transform them into powders. This includes both organic and inorganic chemicals.

- Wastewater Treatment:ATFDs come in clutch in wastewater treatment plants, where they are used to generate solid waste, which is more manageable compared to sludge.

- Pharmaceutical Industry:The pharmaceutical industry exploits agitated thin film dryers to crystallize pharmaceutical compounds, recover essential solvents, and produce APIs.

- Food & Beverage Industry:Quality is paramount when it comes to foods, and ATFDs help produce solid foods such as flavorings and sweeteners by evaporating the moisture in them without diluting their flavor or quality.

- Agricultural Industry:Manufacturers of powdered herbicides, pesticides, and even fertilizers favor ATFDs, since they hardly impact the quality of these agricultural products.

How to Choose the Right Agitated Thin Film Dryer

Every liquid or moisturized product has different features, which necessitate the use of a particular type of agitated thin-film dryer. But how do you get to the ATFD that works the best for you? Here are the factors you need to bear in mind.

- Material Properties:First, you need to understand what type of product you are handling and its unique properties. For instance, how viscous is the raw product, and how sensitive is it to heat?

- Capacity:Your production demands simply dictate the size of the agitated thin film dryer you need. For instance, if you are operating at an industrial level, you will need a large-scale ATFD with the shortest residence time possible.

- Heating Medium:Dissect the dryer’s primary heating medium and how much power it needs to dry your feed product effectively.

- Construction Material:Think of the machine’s construction material and how it interacts with your primary processing product. For instance, if the products are highly corrosive, think about titanium ATFDs, or if your products are foods, go for food-safe stainless steel.

- Vacuum vs Atmospheric:Many a times, the choice of the best dryer for you boils down to vacuum ATFDs or atmospheric ATFDs. If your choice comes down to these two, think of energy efficiency since vacuum ATFDs offer greater energy efficiency.

- Space and Layout:ATFDs come in varying sizes, ranging from small, which favor small drying applications, to industrial sizes custom-made for large operations. Go for a dryer that meets your quantity demands as much as it meets your quality demands.

Comparing ATFD to Other Dryers

| Variables to Compare | ATFD | Rotary Dryer | Fluid Bed Dryer | Flash Dryer |

| Drying Time | Around 10 seconds to 2 minutes. | Over 10 minutes. | Between 10 and 30 minutes. | Approximately 1-5 seconds. |

| Heat Sensitivity | Very short residence time. | Longer residence time. | Moderate residence time. | Extremely short residence time. |

| Energy Efficiency | Low and moderate energy efficiency. | Comparatively lower energy efficiency. | Moderate energy efficiency. | Extremely high energy efficiency. |

| Viscosity Handling | Can handle the most viscous pastes and sludges. | Ideal for moderately viscous materials. | Perfect for lowly and moderately viscous materials. | Ideal for less viscous products. |

FAQs

What Does an Agitated Thin Film Dryer Do?

An ATFD simply evaporates the water or solvent from your wet products, thereby producing solid or powdered goods such as coffee and tablet drugs.

How are ATFDs Different from (Agitated Thin Film Evaporators) ATFEs?

Whereas an ATFD gets rid of the moisture in your feed material in order to produce solid goods, an ATFE evaporates isolated solvents from fluid feeds, leaving you with a highly concentrated liquid.

What Challenges are Common in Agitated Thin Film Dryers?

Despite their unrivalled efficiency, ATFDs come with their share of limitations, which include more moving components that drive your maintenance costs upwards and a higher capital expenditure.

What is the Difference Between an Agitated Thin Film Dryer and a Rotary Dryer?

Whereas ATFDs thrive in drying viscous materials sensitive to heat, rotary dyers excel in drying relatively bigger materials in longer residence times.

Which materials are not suitable for ATFD?

Whereas ATFDs are perfect for most viscous or liquid goods, their effectiveness in drying highly abrasive materials like high mineral salts and hard scaling materials is questionable and highly discouraged.

Can ATFDs operate continuously?

Yes. Although agitated thin film drying machines necessitate routine shutdowns, they can run for hours without straining. This is because they feature self-cleaning rotor blades and boast superior thermal stability.

FanQun is your Trusted Agitated Thin Film Dryer Supplier in China

If you are looking for high quality and reliable Agitated Thin Film Dryer, then FanQun is your trusted partner in China. Our ATFD has designed to meet the strict quality standard for safety and efficiency.

With every purchase for ATFD, you get 24/7 technical support and replacement parts when needed. Our team will also help with the machine installation and training your staff.