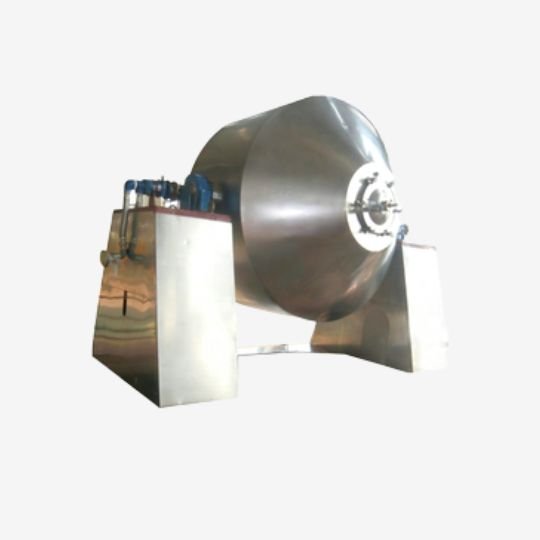

FANQUN Rotary Vacuum Dryer

FANQUN rotary vacuum dryer has advanced technology and modern design, helping you complete drying tasks efficiently.

- Smooth and easy-to-clean inner surface, which ensures a near-complete discharge rate and protects the materials from contamination.

- High sealing provides a sterile environment and prevents material leakage.

- An efficient and stable vacuum system reduces material drying time while ensuring a lower drying temperature.

- The temperature control device accurately measures internal temperature to prevent excessive drying.

- The rotating cylinder ensures that the materials are mixed evenly.

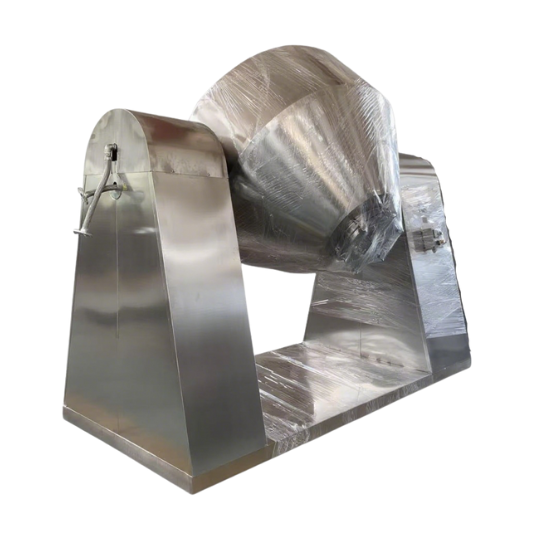

ZFQ-SZG-A Rotary Vacuum Dryer

The main body of SZG series double cone coating vacuum dryer is double cone tank.Inside tank, it always keeps at vacuum situation.steam or hot heat water can be passed in jacket which can heat the internal bladder.heat through jackets passed to wet raw material.It’s makes moisture evaporated.low speed electric engine drives tank to rotate.material are moved up to down and actived inside to out outside hot area are changed instantly.meanwhile.water steam are continually drew out through vacuum pump and vacuum air discharge pipe, this improves the drying speed and achieves aim of average drying.It’s satisfy pharmacy management standard GMP.

Features of ZFQ-SZG-A Rotary Vacuum Dryer

- Drying process in vacuum environment.It has high speed under low temperature,compared to normal drying method,drying speed is improved two times.Energy are saved.heating efficiency is high,this equipment especially suit for heating sensitive material and easy oxidiated.

- This equipment has developed design.inside structure is simple,easy clean.dried material can be discharged totally,operation is easy.

- Sealed drying.products can not be damaged.no pollution.It’s suit for strong simulative and poisonous material.

- Material is rotated and mixed to dry,this can make moisture totally dried.keeps good average condition and suit for various material’s requirements.

- Compacted structures,small occupied area,simple operation,labor strength is reduced and saved.

- Customer can select step-less regulation(1~10r/m) and step regulation (6~10r/m),it’s easy to adjust drying capacity and adopt to different requirement.

A great cylindrical tumble vacuum dryer that enhanced the evaporating control.

Perfect for powdered chemical production, Withstands impact and has great anti-rust quality.

Commonly used in processing dry food products into the standard marketing production, Automatic rotation speed and temperature is adjustable.

Large drum dryer with features high efficiency and energy saving, Carbon steel material that enhances and improves the rotation.

Ideal application for food production, Blade drying material with constant temperature, rotation is speed adjustable.

Manufactured with durable stainless steel material that withstands any dent impact, has an electric heating method.

Switchable rotating vacuum dryer with versatile application, has great energy saving feature.

Continuous and Automatic advantage with High efficiency control and Low energy consumption.

- Our Factory

- Technical Parameters

| Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Volume inside of tank (L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Practical loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 | ≤4000 |

| Rotary speed (r.p.m.) | 3~13 | 6 | 5 | 4 | 4 | 4 | 3.5 | ||||

| Power of motor (kw) | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 37 |

| Occupied area LxW (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 | 4400×2500 |

| Rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 | 4900 |

| Design pressure inside of tank (MPa) | -0.1~0.15 | ||||||||||

| Design pressure of jacket (MPa) | ≤0.3 | ||||||||||

| Working temperature (°C) | In the tank≤85, Jacket≤140 | ||||||||||

| Model and power of vacuum pump | SK-0.4 1.5KW | SK-0.4 1.5KW | SK-0.8 2.2KW | SK-1.5 4KW | SK-1.5 4KW | SK-3 5.5KW | SK-6 11KW | SK-6 11KW | SK-9 15KW | SK-12 18.5KW | SK-15 22KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 | 10000 |

Remark: For raw material, if its volume has great change before and after dry, then its filling coefficient may be increased or decreased suitably.

What is A Rotary Vacuum Dryer?

A rotary vacuum dryer is a drying machine that heats, mixes, and dries materials in an internal vacuum environment. It is used for heat-sensitive and oxygen-free materials requiring low-temperature drying, with different forms, including wet cakes, slurries, powders, and granules.

Types of Rotary Vacuum Dryers

Based on the shape of the cylinder, the rotary vacuum dryers can be divided into horizontal rotary vacuum dryers and double cone rotary vacuum dryers.

Horizontal Rotary Vacuum Dryer

It has a cylindrical body lying horizontally on the shelf, and an agitator inside it. This type of dryer has a larger loading volume and is suitable for all kinds of materials. The material is dried by the rotation of the cylinder and the stirring of the agitator in the horizontal rotary vacuum dryer.

Double Cone Rotary Vacuum Dryer

The double cone rotary vacuum dryer has a compact cylinder and two symmetrical cones at the top. It doesn’t have an agitator, and the material is gently mixed by the low-speed rotation of the cylinder.

It is suitable for materials that need to be dried at low temperatures and preserve crystal structure, especially suitable for materials that are easily oxidized, volatile, highly heat-sensitive, or toxic.

Rotary Vacuum Dryer Working Principle

Rotary vacuum dryers dry materials by rotating, heating, and increasing the vacuum level.

Driven by the drive unit, the cylinder rotates, causing the material to continuously tumble, mix, and be exposed to the vacuum environment.

A heat transfer material is injected into the interlayer, and heat is transferred to the material through the inner wall. The moisture in the dried material evaporates after reaching the evaporation temperature.

The air pressure inside the dryer can be adjusted by the vacuum system. The vaporization point of water decreases under low air pressure, allowing it to vaporize at a lower temperature. The moisture in the dried material evaporates at a suitable temperature and is promptly discharged by the vacuum pump.

Key Parts of A Rotary Vacuum Dryer

The Main Dody

The main body of a rotary vacuum dryer is made of metals, like stainless steel and carbon steel. The inner wall is made of SS316 stainless steel, which is heat-resistant and corrosion-resistant. We add a special coating to the inner wall of our rotary vacuum dryers, which has better anti-sticking and corrosion resistance. Our double cone rotary vacuum dryer has a pulse jet dust filter inside it, which can clean the inner wall of the dryer efficiently.

The cylinder rotates at a speed of 4-6 rpm, ensuring that the materials are mixed evenly without damage.

Agitator

Horizontal rotary vacuum dryers contain an internal agitator. The agitator blade has many types, including spiral ribbon blades, paddle blades, and some special blades. The agitator can break up lumpy materials and materials with high viscosity, mixing them evenly and increasing their exposure to a vacuum environment.

Vacuum System

Usually, the vacuum system is equipped with nitrogen purging, a vacuum release device, a dial vacuum gauge, and a leak-proof vacuum device. The dial-type vacuum gauge is used to monitor the vacuum level in real time. Controlling the vacuum level can affect the drying speed. Our vacuum system can achieve an ultimate vacuum of <5 mbar within 15 minutes.

The vacuum system can create and maintain a vacuum environment to lower the vaporization point and shorten the drying time, thus accelerating drying efficiency and improving overall production efficiency.

A vacuum environment is very suitable for drying materials that are easy to oxidize, reducing their risk of deterioration during drying.

Heating System

The heating system of a rotary vacuum dryer is mainly made of the interlayer or coils of the machine body. Heating media typically include steam, hot water, and hot oil, and some rotary vacuum dryers can be heated by electric heaters or hot air. The interlayer or coil that is added with heating material can transfer heat to the inner wall and dry the material.

The interlayer and insulation layer are made of 304 stainless steel, which is durable and corrosion-resistant. Our insulation layer uses low-energy aluminum silicate as the heating material. It achieves sustainable energy conservation based on the heat preservation function compared to welded mineral wool and glass fiber wool.

The interlayer is equipped with a drain plug and a safety valve to ensure that the heating media can be poured into the interlayer under safe pressure. Our coils and interlayers are equipped with a thermosiphon system. A thermometer monitors the internal temperature in real time.

Condenser

It recycles the solvent through condensing solvent vapor. The condenser is made of SS304, which can safely handle the flame-retardant solvents. Some organic solvents are environmentally friendly and can prevent harmful chemicals in steam from damaging the atmosphere.

Advantages

Maintain Product Integrity

Drying in a vacuum environment allows the moisture inside the material to evaporate directly, and the dryer maintains a stable, low temperature. These features avoid the surface hardening phenomenon, thus preventing the dried material from deformation or breakage.

Reduce Drying Time

Compared to traditional drying, rotary vacuum dryers can complete the drying task in a shorter time, even shortening the entire production line time, because the high-vacuum environment requires a lower temperature.

Prevent Material Oxidation

For sensitive compounds that are easily oxidized, vacuum drying can prevent oxidation. Our rotary vacuum dryer has high airtightness, isolating air and bacteria during the drying process and ensuring the quality of the dried material.

Batch Processing Capability

Horizontal rotary vacuum dryers have a large capacity and can process large quantities of material at one time. The agitator ensures that each particle of the material is fully exposed to the vacuum environment, achieving uniform drying.

Applications

Pharmaceutical Industry

Traditional Chinese herbal extracts: Astragalus membranaceus and Salvia miltiorrhiza. Vacuum drying preserves the nutrients in these extracts during drying, ensuring the quality of the traditional Chinese herbal extracts. Some traditional Chinese herbal extracts are quite viscous, and the rotating cylinder and smooth inner wall prevent sticking.

Intermediates: Particle intermediates that require maintaining a specific particle size distribution.

Active pharmaceutical ingredients (APIs): Antibiotics, vitamins, hormones, and certain anticancer drugs. These drugs contain temperature-sensitive crystals, and the gentle rotation and mixing in a rotary vacuum dryer do not damage these crystals. The strictly sterile environment inside our rotary vacuum dryer meets the hygiene standards for APIs.

Biological products: Certain enzyme preparations, vaccines.

Chemical Industry

Fine chemicals: catalysts, colorants, paints, coatings, adhesives.

Specialty chemicals: Hazardous chemicals, such as explosives and petrochemicals. These chemicals require careful temperature control during heating to prevent reactions.

High-viscosity polymers: Polyvinyl alcohol (PVA), polyacrylamide, and polymer-TDI. These polymers require careful handling during heating to prevent localized overheating and clumping.

Basic chemicals: Organic and inorganic substances.

Foods

Seasonings: Excessive heating time and high temperature can easily cause them to deteriorate and even produce harmful substances.

Dehydrated products: such as dried fruit, dried meat, and dehydrated vegetables. Drying prevents these foods from getting mouldy, extends their shelf life, and preserves their nutrients and flavor.

Dairy products: milk powder, cream. Temperature control is crucial to this kind of food. Suitable temperature prevents protein denaturation and fat oxidation, thus preserving the nutrients and flavor of dairy products.

FANQUN is a professional rotary vacuum dryer supplier, with forty years of experience in the research and development, and manufacturing of drying equipment. We are committed to providing you with high-quality rotary vacuum dryers. Schedule a free consultation, and you’ll receive a personalized free vacuum drying solution.

The condition of the material to be dried: The looser the internal structure of a material, the faster it dries.

Amount of solvent or water to be removed: The higher the moisture content and viscosity of the material, the longer the drying time is required.

Temperature: The drying temperature that the material can bear should be selected based on its heat sensitivity, and excessively high temperatures will affect the quality of the material.

The roller motion of a rotary vacuum dryer helps to dry the material evenly, preventing localized overheating and clumping, which ensures the material’s quality.

Our rotary vacuum dryers are specially designed and cleaned to meet specific standards for the pharmaceutical and food industries.

The inner walls are polished and have a no blind spots design to ensure no dirt remains during cleaning. For food and pharmaceutical materials with hard hygiene requirements, we offer a SIP (Self-Installation Injection) solution, which can kill microorganisms and spores without disassembly, preventing cross-contamination.

Rotary vacuum dryers dry materials in a vacuum environment, which ensures a lower vaporization point and reduces heating energy consumption. Because of the lower vaporization point, the heating time is also shorter, resulting in less energy consumption during the drying process. Unlike traditional drying equipment, the lower heating temperature prevents surface hardening, which will prolong the drying time.

We have efficient production lines and a large production scale, which significantly reduces production costs while ensuring quality.

Based on reduced production costs, we invest heavily in technological research and development to improve the dryer’s performance and efficiency, ensuring our dryers can adapt to the ever-evolving modern industry.

Dryer quality: You can inspect the dryer on-site to assess its quality, or request the supplier to provide quality certification documents such as ISO 9001. Only suppliers that can provide stable, high-quality rotary vacuum are worthy of long-term cooperation.

Delivery capability: You can check out the historical orders of this supplier to see if products can be delivered on time and whether they have long-term partners. When meeting unforeseen circumstances, a supplier’s emergency strategies and alternate supply plan reflect its delivery capabilities.

After-sales service: The supplier’s after-sales service is reflected in basic services, including returns and exchanges, repairs, refurbishments, and on-site services.