FANQUN Conical Vacuum Dryer

FANQUN conical vacuum dryer operates safely and stably, and helps you dry your products, ensuring purity and integrity.

- Larger heating area than a common conical vacuum dryer

- High sealing with a no blind spots design, preventing cross-contamination

- High vacuum within an appropriate range

- 99.9% discharge rate, minimising product loss

- High-efficiency energy-saving device that can recover solvent steam completely

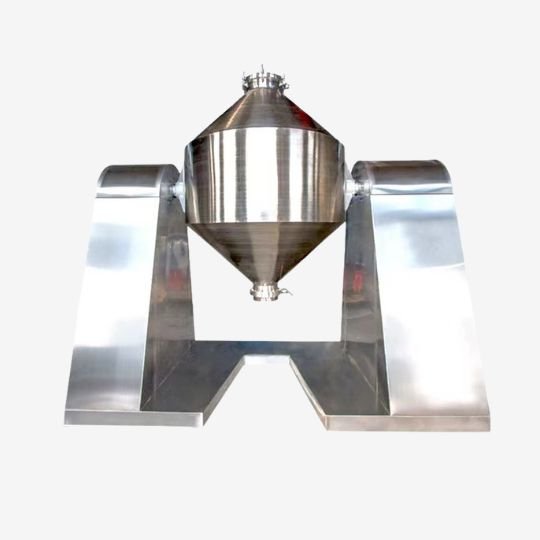

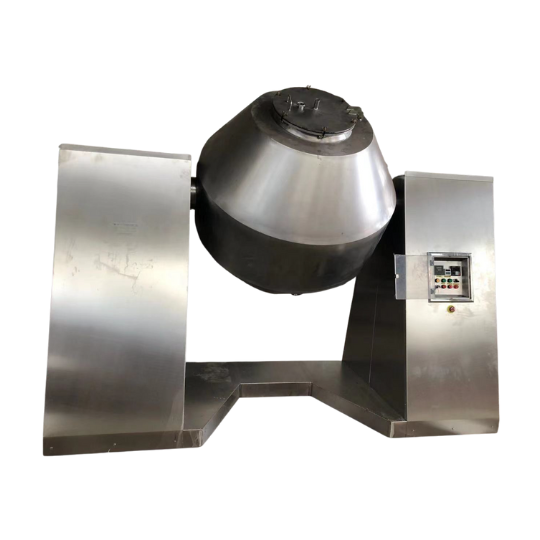

ZFQ-SZG-B Conical Vacuum Dryer

The main body of SZG series double cone coating vacuum dryer is double cone tank.Inside tank, it always keeps at vacuum situation.steam or hot heat water can be passed in jacket which can heat the internal bladder.heat through jackets passed to wet raw material.It’s makes moisture evaporated.low speed electric engine drives tank to rotate.material are moved up to down and actived inside to out outside hot area are changed instantly.meanwhile.water steam are continually drew out through vacuum pump and vacuum air discharge pipe, this improves the drying speed and achieves aim of average drying.It’s satisfy pharmacy management standard GMP.

Features of ZFQ-SZG-B Conical Vacuum Dryer

- Drying process in vacuum environment.It has high speed under low temperature,compared to normal drying method,drying speed is improved two times.Energy are saved.heating efficiency is high,this equipment especially suit for heating sensitive material and easy oxidiated.

- This equipment has developed design.inside structure is simple,easy clean.dried material can be discharged totally,operation is easy.

- Sealed drying.products can not be damaged.no pollution.It’s suit for strong simulative and poisonous material.

- Material is rotated and mixed to dry,this can make moisture totally dried.keeps good average condition and suit for various material’s requirements.

- Compacted structures,small occupied area,simple operation,labor strength is reduced and saved.

- Customer can select step-less regulation(1~10r/m) and step regulation (6~10r/m),it’s easy to adjust drying capacity and adopt to different requirement.

Chemical usage conical vacuum dryer and size customizable for commercial or industrial application.

Temperature controlled cone and has large capacity for heavy materials. Strong manufactured material.

Vacuum drying equipment that ensures great temperature drying, Customization of the machine is available.

Often used in chemical production and powder granulation, it dries the moisture out thoroughly with less energy consumption.

A mixer with high-quality function for more thorough mixing, this gives the granulated material is thoroughly blended.

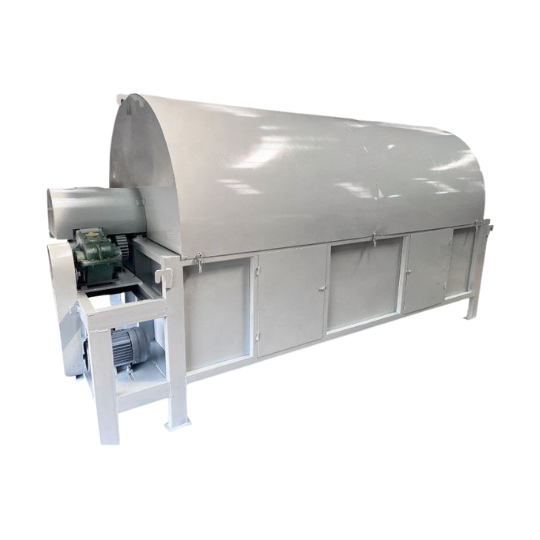

Continuous rotating dryer with enclosed interior that is enhanced by durable manufactured material. Customization of the dryer involves dimension and sizes.

Multi-functional cones with syncable temperature adjustment. Electricity and Gas heat source, Both have continuous and automated control.

Chemical and Food processing, Multifunctional and advanced features. Multiple heating methods and continuous mixer.

- Our Factory

- Technical Parameters

| Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Volume inside of tank (L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Practical loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 | ≤4000 |

| Rotary speed (r.p.m.) | 3~13 | 6 | 5 | 4 | 4 | 4 | 3.5 | ||||

| Power of motor (kw) | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 37 |

| Occupied area LxW (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 | 4400×2500 |

| Rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 | 4900 |

| Design pressure inside of tank (MPa) | -0.1~0.15 | ||||||||||

| Design pressure of jacket (MPa) | ≤0.3 | ||||||||||

| Working temperature (°C) | In the tank≤85, Jacket≤140 | ||||||||||

| Model and power of vacuum pump | SK-0.4 1.5KW | SK-0.4 1.5KW | SK-0.8 2.2KW | SK-1.5 4KW | SK-1.5 4KW | SK-3 5.5KW | SK-6 11KW | SK-6 11KW | SK-9 15KW | SK-12 18.5KW | SK-15 22KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 | 10000 |

Remark: For raw material, if its volume has great change before and after dry, then its filling coefficient may be increased or decreased suitably.

What is a Conical Vacuum Dryer?

The drying method of a conical dryer is to heat the material inside by heating the inner wall of the dryer. In an environment that is almost a vacuum, the tank and agitator rapidly and comprehensively tumble the product to mix and dry it. The moisture inside the product is heated and vaporised, turning into water molecules that enter the vacuum space. Commonly, the effective volume of a conical vacuum dryer can be from 10 litres to 10,000 litres.

The Composition of a Conical Vacuum Dryer

The Dome of the Dryer

The outer surface includes a vacuum port, sight glass, air outlet, filter, and feed inlet. The interior of the dome contains rotating cleaning nozzles and cleaning equipment.

The Body of the Dryer

The body materials are typically divided into three layers, which are the outer wall, the heat exchange interlayer, and the inner wall, from the outside to the inside.

The outer wall: the materials for the outer wall are stainless steel, carbon steel, or alloy materials. We offer a variety of alloy materials, such as 304, 316L, and C22 alloy. The outer wall of the conical vacuum dryer is polished, so it not only looks aesthetically pleasing but also provides excellent sealing and corrosion resistance.

Heat exchange interlayer: There are heat pipes and heat exchange devices in the heat exchange interlayer. This interlayer has a good airtight seal with the outer wall, preventing air leakage. Our conical vacuum dryers have a three-dimensional heat dissipation device, and the heat dissipation area is 10 times that of a dryer of the same volume. This device allows the dried material to contact a larger heat-receiving area, improving drying efficiency.

The heat transfer medium can be low-pressure steam, or fluids such as hot water, heat transfer oil, or electricity. The heat source pipes keep a distance from the vacuum system piping to prevent the temperature from affecting the vacuum pump’s pumping speed.

The inner wall: The smooth inner wall ensures a high discharge rate of 99.9%. When cleaning it, the smooth inner wall ensures that the cleaning liquid can be completely drained.

Agitator

The agitator is made of a central stirring shaft and a surrounding hollow spiral band. It has two types of conical and cylindrical cones. The surrounding hollow spiral band is usually made from corrosion-resistant materials such as stainless steel.

When mixing dried materials, the moisture can evaporate faster and be drawn away by the vacuum system, indirectly reducing the pressure inside the dryer.

The continuous tumbling action of the agitator increases the surface area of the dried material and the heating components, preventing the materials clumps or overheating due to uneven heating.

Dryer Chassis

It supports the entire conical vacuum dryer, ensuring that the machine does not shake during operation. The chassis is equipped with a discharge valve, and we use a ball valve-type discharge valve.

Sampling Device

The sampling device allows us to take samples from the dried material to test the effectiveness of the samples when drying.

Weighing Sensor

The weighing sensor can weigh the dried materials quickly and accurately. Accurate weighing is crucial for quality control of dried materials.

Backflush Device

During drying, the vacuum channels can easily be blocked by dried particles, reducing drying efficiency. We have equipped our equipment with a back-flushing device.

The Types of Conical Vacuum Dryers

Both the conical spiral vacuum dryers and vacuum rake dryers use internal agitators to rotate, but the dryer bodies don’t rotate. In contrast, the double cone rotary vacuum dryer uses the dryer body to rotate.

Conical Spiral Vacuum Dryer

It is the most common type of conical vacuum dryer. The body of the dryer remains silent, and the internal agitator rotates, making the product move continuously and come into constant contact with the inner wall for heating and drying.

The conical inner wall gives it a lower shear force. It is suitable for ultrasensitive powders in pharmaceuticals and fragile food in chemicals. Some thick and wet products can also be used for drying.

Vacuum Rake Dryer

Unlike traditional conical vacuum dryers, rake dryers have a special rake-shaped agitator, which is made of a central mounting shaft and a stirring rod on the shaft. The short rod at the end of the stirring rod resembles a rake. The ends of the stirring rods fit snugly against the inner wall of the dryer, leaving small gaps.

This dryer type offers a wider mixing range and uniformity. Compared to spiral vacuum dryers, its mixing method is gentler and can effectively protect the crystal structure of materials.

Double Cone Rotary Vacuum Dryer

It has two symmetrical, conical ends with a short, thick middle cylinder. The machine body rotates and causes the product to be continuously scattered inside, allowing it to naturally spread as the machine tumbles. This is suitable for materials that do not easily clump together, such as powders, crystals, and granules.

Advantages

Low-shear Drying

Shear refers to the pressure exerted on the dried material by the spiral or stirring rod of the agitator during the drying process, and is determined by the design and rotational speed of the agitator. Our conical vacuum dryer achieves low-shear drying and gentle stirring through its unique profile design, meaning that it can dry under very low power.

Full Discharge

Generally, paste materials with high viscosity have a low discharge rate after drying. However, our equipment has a very smooth inner wall with no dead corners, which can reduce adhesion. Some dryers with high value can achieve complete non-stickiness with PTFE coating in the inner wall.

The conical vacuum dryer is designed with a reasonable tilting angle to ensure even mixing and drying, preventing localised overheating or clumping.

High Containment

High containment ensures a recovery rate that is close to 99.9% of solids and solvents. The conical vacuum dryer is made from high-quality sealing materials such as silicone and fluororubber, and we check for wear and tear regularly.

High Vacuum

In an environment approaching a vacuum, the vaporisation point of water decreases significantly, allowing conical vacuum dryers to dry products at lower temperatures, which is suitable for temperature-sensitive products.

The high vacuum level also ensures a rapid heat transfer rate, shortening the drying time and improving drying efficiency. For dryer manufacturers having requirements for low energy consumption, a high vacuum level is a crucial parameter that must be considered.

Under a vacuum environment, the pressure difference between the product’s interior and surface is significant, causing moisture to quickly move to the surface and avoiding surface hardening. Traditional atmospheric pressure hot air drying can cause surface hardening.

Energy saving and environmental protection

Unlike vertical mixers, it doesn’t have a transmission system and doesn’t have to worry about the product contamination problem caused by lubricating oil leakage.

Conical vacuum dryers are equipped with vacuum drying technology and achieve drying at lower temperatures to save energy. Solvent recovery devices reduce emissions. With technological innovation, vacuum dryers may use even more energy-efficient and environmentally friendly solvents and materials.

Applications

The drying process is important for product quality and production efficiency. The conical vacuum dryer is especially suitable for powders and granules with high hygiene requirements, viscous liquids, and thick, wet materials.

Pharmaceuticals Industry

Some medications have heat-sensitive ingredients and can only be dried through a vacuum dryer.

Active pharmaceutical ingredients in Western medicines such as antibiotics, protein drugs, and sterile raw materials. Among them, sterile raw materials have high requirements for hygiene standards. When drying, we ensure that steam permeates every corner of the pharmaceutical vacuum dryer, creating a sterile environment.

Traditional Chinese herbal extracts, such as extracts of Astragalus membranaceus and Salvia miltiorrhiza. Traditional oven drying can lead to the loss of active ingredients of Chinese herbal medicine. A conical vacuum dryer ensures the quality of important extracts.

Chemical Industry

Chemical materials are easy to generate volatile organic compounds, so the conical vacuum dryer used must avoid localised overheating during the drying process.

High-viscosity polymers, such as polyvinyl alcohol (PVA) and polyacrylamide.

Speciality chemicals have higher value and functions compared to ordinary chemicals, requiring careful temperature control during heating to prevent chemical reactions.

Fine chemical intermediates, such as dyes, pigments, catalysts, rubber, and plastics. These products need a stable environment to be kept.

Easily oxidizable materials, such as organometallic compounds.

Foods

Dairy products, such as milk powder and cream. When drying dairy products, excessively high temperatures are avoided. High temperatures cause fat oxidation, damaging the flavour and taste of the dairy products.

Dried fruit, vegetables, meat, etc. Drying food can prevent it from getting mouldy and extend its shelf life.

Natural extracts, such as juice powder and flavourings. Vacuum drying can preserve natural substances such as anthocyanins, retaining their original colour and nutrients.

Functional food, such as probiotics and dietary fibre. Probiotics are live microorganisms, and their bacterial proteins are highly sensitive to temperature. The drying temperature must be kept below 45°C to retain their activity. Our dryers can achieve stable drying at temperatures below 40°C, ensuring temperature fluctuations are less than 2°C.

Metallurgical Industry

Some metals and ores: The moisture in metals and ores can affect purity, and removing moisture using a dryer can improve their purity. Commonly, higher purity means higher value.

Electronics Industry

Moisture can cause damage to electronic materials during manufacturing. Drying these electronics improves the quality and reduces the failure rate.

Precursors for lithium-ion battery cathode materials, such as nickel-cobalt-manganese hydroxide (NCM).

Nano-oxides such as titanium dioxide.

FANQUN is a supplier that is committed to the manufacture of conical vacuum dryers with 34 years of experience and a professional manufacturing team of 500 employees. Click the free consultation button below, and you will get a preliminary drying plan for your product or material.

The delivery time is determined by many factors, like equipment model and specification.

Equipment model: the conical spiral dryer of the standard model has a shorter delivery time, and the customised one has a longer delivery time.

Specification: The conical spiral dryer with standard specification has a shorter delivery time, while the complex specification needs a longer time to prepare. A complex specification means the equipment has more complex parts and requires more time for production and testing.

The structure and materials of a dryer influence the noise. To reduce it, the rotating structure of the dryer needs to be strengthened, and the outer wall should be made of sound-absorbing or vibration-damping materials. The noise when our dryers are operating is below environmental standards.

The drying speed is related to many factors, including the condition of the material itself and the performance of the dryer.

The condition of the dried materials: Temperature, density, viscosity, and moisture content.

Pretreatment of dried materials: Pre-treating materials can shorten the drying time and reduce product loss. For example, if there are some large particles in the material, you can crush them appropriately or undergo granulation treatment. If the viscosity of the dried material is high, you can add an anti-sticking agent.

The vacuum level of the dryer: The common vacuum level is not less than 1*104 Pa. Generally, the higher the vacuum level, the lower the temperature required for vaporisation. However, excessively high vacuum levels are unfavourable to heat conduction.

The inner wall of the dryer needs to be in contact with dried material, so keeping the inside of the equipment clean is crucial to prevent pollution. The hygiene standards of our conical spiral dryers all meet GMP requirements.

The situation of your dried materials: Moisture content, density, viscosity, and heat sensitivity.

Solvent: Composition, boiling point, and corrosiveness.