FANQUN Niro Spray Dryer

FANQUN’s Niro spray dryer system,based on mature rotary atomization technology, provides customers with efficient,stable and customizable drying solutions. We are a professional Niro spray dryer manufacturer.

- FANQUN’s Niro spray dryer system’s professional design philosophy and mature engineering experience ensure the long-term stable operation of your production line.

- This spray dryer system perfectly resolves the problem of material sticking to the walls. Its superior tower design and air distribution system ensure uniform drying of the material, guaranteeing powder consistency. This also reduces downtime for cleaning,ensuring production continuity and indirectly lowering your production costs.

- FANQUN’s Niro spray drying equipment protects the activity of heat-sensitive components in materials, perfectly preserving the flavor of spices and the activity of products such as enzymes.

- We can customize high-efficiency thermal energy utilization and closed loop drying systems to meet your needs. This can help you reduce product energy consumption and improve overall economic efficiency.

What is a Niro Spray Dryer?

Our Niro style spray dryers represent exceptional reliability, precise process control and top tier powder quality. Their core lies in the combination of high speed rotary atomization technology and tower airflow design, producing extremely uniform atomized droplets and achieving highly efficient heat exchange instantaneously. FANQUN’s Niro spray dryers are widely used in the pharmaceutical, probiotic, plant extract and fine chemical industries.

If you require a repeatable,cost effective and customized solution, choose FANQUN Niro spray dryer. Choosing us means choosing proven and professional process technology validated by countless projects.

Working Principle of Niro Spray Dryer

The essence of FANQUN Niro spray dryer lies in its ability to transform complex drying processes into stable, repeatable, and industrial production through uniform atomization, precise airflow control, and flexible modular design. This reliably converts your liquid formulations into high-quality powder products with market competitiveness, while maximizing the preservation of the activity of heat-sensitive components.

The workflow in operation is as follows:

Step 1: Precision atomization

Atomization of liquid material into billions of uniform droplets is the most crucial step in determining the final powder particle size.The liquid material is delivered to the center of a high-speed rotating atomizer, where it is shaped into uniformly sized fine droplets by the immense centrifugal force of the high-speed rotating disc (speeds up to 15,000-20,000 rpm).

Step2: Instant drying

Filtered and heated clean hot air enters the top of the spray dryer tower in a stable and uniform spiral or laminar flow state through a unique air distributor. The atomized material droplets mix instantly with the hot air at the top of the tower. FANQUN Niro spray dryer’s design where the hot air moves in the same direction as the droplets, ensures that the wettest droplets contact with the hottest air. Subsequently, the particle temperature drops rapidly due to moisture evaporation, which perfectly protects heat-sensitive ingredients of material.

Step3: Gas powder separation for efficient collection of powder

The airflow carrying the dried powder enters the cyclone separator from the bottom of the spray dryer tower, where centrifugal force separates most (>95%) of the coarser particles.The exhaust gas containing fine powder enters a bag filter for final, highly efficient collection, achieving a collection efficiency of over 99.9%, ensuring product yield and compliance with environmental emission standards.

Suitable for small batch experiments, the evaporated amount of moisture is within 5 kg/h-25 kg/h, the temperature can precise control.

With industrial grade centrifugal atomizer,PLC automatic control,applicable to small batch continuous production.

Heating with multiple methods,the evaporated amount of moisture is more higher,operating stably in large-scale.It is widely used in food,chemicals,etc.

We can customize large production lines based on your feed material,factory layout and production capacity.

Suitable for multiple product categories,powder with uniform particle size distribution,offering large processing capacity.

The output powder has a finer particle size, making it suitable for functional foods and chemicals to create a refined product roadmap.

It is suitable for heat-sensitive materials, but its low feed rate and high energy consumption make it more suitable for experiments and small-scale production.

This device is uncommon and is mainly used for scientific research.It utilizes ultrasonic atomization to form ultrafine droplets.

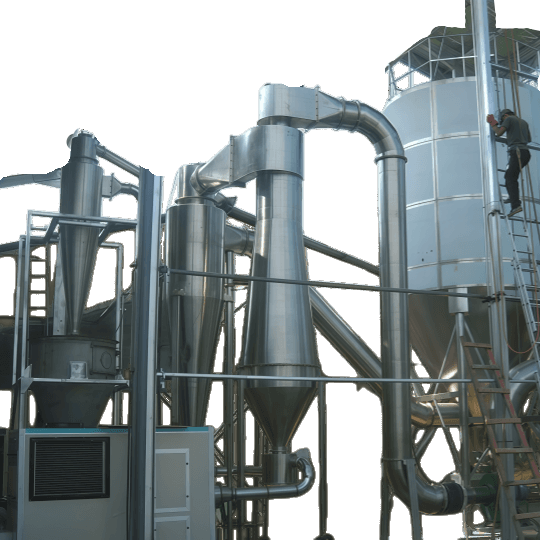

- Our Factory

- Technical Specifications

| Model | N-25 | N-50 | N-100 | N-150 | N-200 | N-300 | N-300-5000 |

|---|---|---|---|---|---|---|---|

| Evaporated Moisture (kg/h) | 25 | 50 | 80 | 100 | 150 | 200 | 300–5000 |

| Inlet Air Temperature (°C) | 150 – 300 | ||||||

| Outlet Air Temperature (°C) | 70 – 110 | ||||||

| Atomization Method | Centrifugal Atomizer / High-Pressure Nozzle | ||||||

| Final Moisture of Product (%) | Typical final moisture: 3–5% (depending on material and process conditions) | ||||||

| Electric Power (kW) | 50 | 82 | 117 | 150 | 238 | 320 | Depends on actual situation |

| Heating Method | Electric Heating / Steam / Gas Heating | ||||||

| Automatic Control | PLC automatic control system with real-time monitoring of inlet/outlet air temperature, exhaust air humidity, and safety interlocks | ||||||

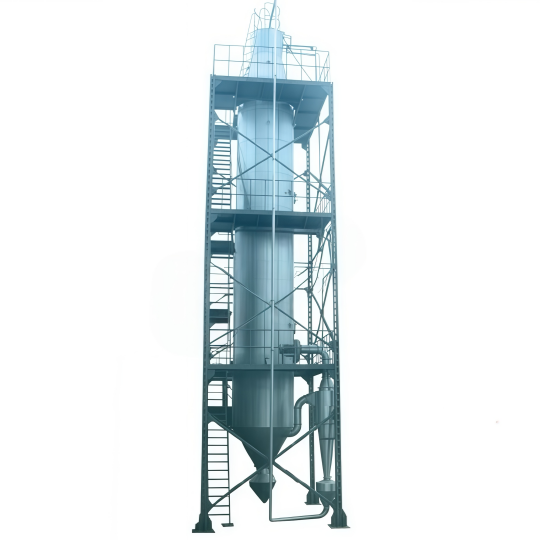

| Overall Dimensions (L×W×H) (mm) | 6145×1500×9300 | 6875×1700×11300 | 7765×1980×14500 | 8785×2650×17000 | 9700×2800×18700 | 10900×3000×21000 | Depends on actual situation |

| Note: This is a NIRO-type spray dryer designed based on NIRO spray drying principles. | |||||||

Key Components of a FANQUN Niro Spray Dryer

Liquid material feed system

A stable and continuous feed system contains raw material type with agitation and high pressure feed pump. It stably and controllably delivers the liquid (solution, suspension, emulsion) to the atomizer. Liquid material feed system ensures uniform droplet formation and stable consistent powder quality.

Atomization system

This system is configured with centrifugal atomizer(rotary atomizer) and high pressure nozzle atomizer. The centrifugal high speed rotary atomizer breaks the liquid into uniform and fine droplets, greatly increasing its surface area for instant drying. FANQUN Niro spray dryer’s atomization system is good at droplet size controlling and it is adaptable to different viscosities and solid contents. Precise atomization directly determines particle size distribution, bulk density and solubility of the final powder.

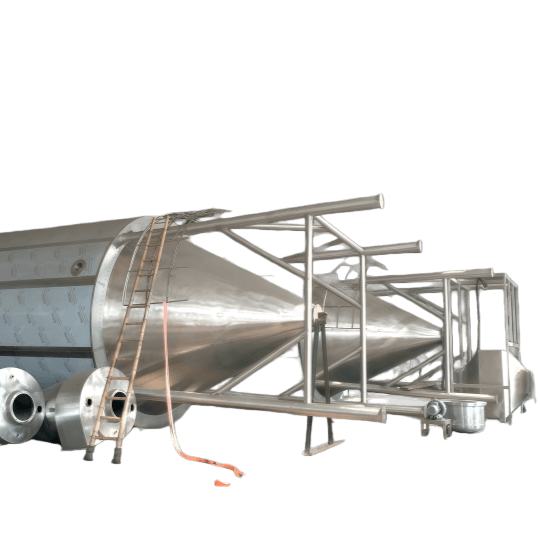

Niro spray dryer chamber

Niro spray dryer chamber is a large vertical cylindrical cone-shaped structure chamber. It provides sufficient residence time for the droplets to dry completely.The FANQUN Niro spray dryer chamber’s cone angle design,smooth inner wall, thermal insulation performance and observation cleaning ports are all designed to optimize powder flow, prevent adhesion and facilitate cleaning.

Air Heater&Distribution System

The air heater system includes steam heater, direct gas heater, electric heater, or thermal oil heater. It heats the intake clean air to the precise process temperature (typically 150°C – 300°C, depending on the material). The hot air system precisely controls inlet air temperature. It ensures efficient drying and prevent overheating or product degradation.

Advantages of Niro Spray Dryer

Compared with the traditonal spray dryer, the Niro type spray dryer has the following advantages:

Niro Spray Dryer for Heat Sensitive Materials

Once the material is heated for too long, its structure will be damaged. The material will deteriorate and the product will be completely useless. The hot air from Niro spray dryer comes into instant contact with the droplets, which shortens the residence time of the material. The moisture in the material will evaporate in an instant. This ensures that the material will not deteriorate.

Cost Savings

The machine can operate continuously for 24 hours without interruption, with a high mechanical utilization rate. This reduces the losses caused by idle machines. Machine operation is simple. It usually need only 1-2 people to start and stop.The Niro spray dryer can record operating data, and perform normal inspections. This also saves labor costs.

More stable product quality

Our Niro spray drying equipment’s atomization system can choose different atomizers to determine the different sizes of powder particles. The continuous feeding system ensures even droplet distribution during operation. At the same time, it also ensures consistent powder quality and minimal differences in product batches.

Application of Niro Level Spray Dryer

Our Niro type spray dryer can be used for chemical, pharmaceutical and food (dairy products, milk powder) industries.

Niro Spray Dryer in Food Industry

In the food industry, preserving the color, taste, and nutritional content of food is our top concern. Our Niro spray dryer focuses on the activity retention and flavor locking of thermosensitive materials. Our equipment ensures that products such as whole milk powder or skimmed milk powder, whey protein, probiotics, instant beverage extracts, etc. Our Niro type spray dryer maintain solubility, biological activity, and natural flavor. And meanwhile it achieves extremely low moisture content. Niro spray dryer has a long history of application in dairy products, milk powder and other fields.

Niro Spray Dryer for Pharmaceutical

We can provide compliant closed drying solutions for APIs (active pharmaceutical ingredients), traditional Chinese medicine extracts, antibiotics, enzyme preparations, vaccine adjuvants, etc.

If you need medicine spray dryer, traditional Chinese medicine extract drying, antibiotic drying production line, enzyme activity protection drying, sterile spray drying, etc., our Niro spray dryers are your good and clever choice. The Niro spray dryer system supports the complete recovery of organic solvents to ensure the consistency of drug purity, active ingredient retention, powder batch quality and absolute production safety. This is particularly important for the pharmaceutical industry.

Niro Spray Dryer for Chemicals Industry

FANQUN Niro spray dryer can be customized more flexibly, with strong controllability and many adjustable parameters. These characteristics can solve the problem of large material differences in the chemical industry. It is widely used in advanced ceramic powders, lithium battery materials, pigment dyes, polymer resins and other fields. Niro type spray drying is a key process step for obtaining high-performance terminal materials.

How to Choose Niro Type Spray Dryer

Choosing a Niro type spray dryer requires your budget and the required equipment size. And there are comprehensive evaluation of various factors. The Niro type spray dryer is a higher standard spray dryer, so you must ensure it meets your actual needs before purchasing. Below are some summarized steps for your choice.

Step 1: Material Properties

Before purchasing you need to clarify certain characteristics of your material, such as solid content, viscosity, and thermal sensitivity. Different materials require different atomization methods, chamber designs, and drying temperatures.

Step 2: Target Powder Characteristics

The Niro spray dryer does not merely remove moisture from materials.It is designed to control parameters such as particle size distribution, bulk density, flowability, dispersibility, and final moisture content. Niro spray dryer for pharmaceuticals and dairy ensure more stable product quality. It is particularly important.

Step 3: Selection of Atomization System

The Niro spray dryer atomization system is divided into centrifugal atomizers and high pressure nozzles. We usually select centrifugal atomizers if a large amount and uniform particle size of target powder are needed. High pressure nozzles are more suitable for producing smaller particle size powder.

Step 4: Evaluate the drying chamber and heat flow design

Here are three questions we have summarized when we evaluate the Niro spray dryer chamber and heat flow design:

- Can airflow design protect heat sensitive materials while ensuring dryness?

- Is the duration of material stay in Niro spray dryer chamber controllable?

- Is the distribution of hot air uniform?

Step 5: Stability of Niro spray dryer and engineering experience of the factory

The equipment needs to keep running continuously without intermission. The Niro spray dryer supplier needs to provide long-term technical services. We has a certain ability to customize the Niro spray dryer based on the characteristics of raw materials.

Jiangsu Fanqun is a professional drying equipment factory,having over 25 years extensive experience in food,pharmaceutical and chemical industries.We provide niro level spray dryers designed based on proven niro spray drying concept,offering customized capacity,flexible configuration, and reliable performance. If you need a drying solution,please contact our team,we will give you a free technical solution.

No, it is a synonym for high standard spray dryers. Most of the Niro spray dryers in the market are self-designed and manufactured. And these spray dryer’s structures and concepts come from Niro.

Choosing Niro spray dryer means that you have higher requirements for powder quality and stable operation. We can design the Niro spray dryer system for you according to your materials and requirements. Our clients’ common industries include traditional Chinese medicine extracts in pharmaceuticals, infant milk powders in dairy products, and catalysts in the chemical industry.

Yes.The Niro spray dryer use a mature atomization system to ensure a stable particle size of the powder during a long time of operation. The Niro spray dryer can control the solubility and bulk density accurately.

Yes. We need your basic process data and on-site conditions. Our experienced and professional engineers will discuss with you for free and determine a Niro spray dyer system solution that suits you.