FANQUN Centrifugal Spray Dryer

FANQUN ‘s centrifugal spray dryer can evaporate over 95% of moisture within seconds, making it suitable for drying heat sensitive materials.

- A centrifugal spray dryer can evaporate 95% to 98% of the moisture from a liquid feed within seconds.

- For raw materials with moisture content between 40-60%, a single drying step can produce powder or granular products.

- You can modify the product’s properties including particle size, bulk density, and moisture content by adjusting the atomizer speed and inlet air temperature and other parameters.

- Our centrifugal spray dryers have achieved ISO 9001 certification.

- We have ten product patents.

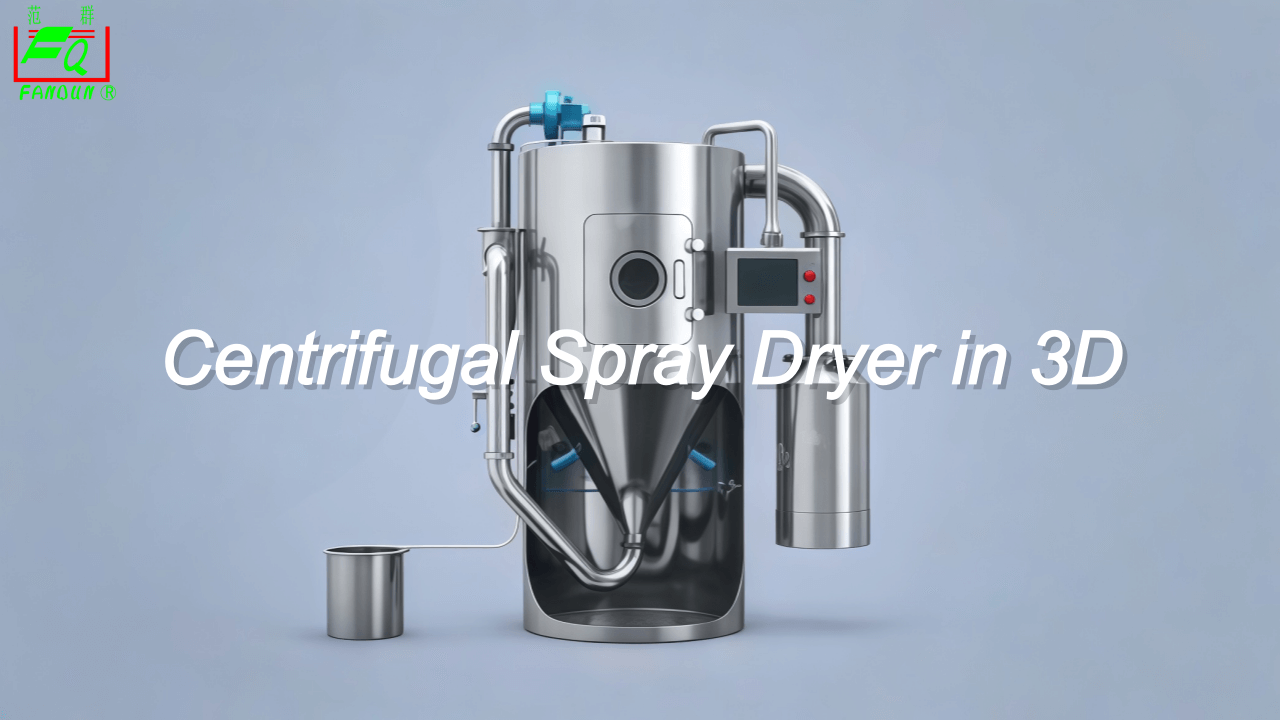

3D Structure & Airflow of FANQUN Centrifugal Spray Dryer

This video shows how liquid feed is atomized by the high-speed centrifugal spray dryer and efficiently dried through controlled hot air circulation, ensuring uniform particle formation, high drying efficiency, and stable operation.

LPG Series Centrifugal Spray Dryer

LPG series high-speed centrifugal spray dryer is a special equipment and is suitable for drying emulsion,suspending liquid,liquor and so on.Particularly it has unique advantage for drying polymers and resins; dyestuff and pigment; ceramics,glass; derust agent; pesticide;carbohydrate,dairy products; detergent and surfactant; fertilizer,organic compound,inorganic compound and so on.

Principle of LPG Series Centrifugal Spray Dryer

Air is turned into hot air filter and heater and enter into hot air distributor at the top of dry chamber and then enters into dry chamber spirally and evenly.At the same time liquid of raw material is sent to centrifugal atomizer at the top of dry chamber pumped by pump through filter.In which liquid of raw material atomizesting droplets.Air and liquid of raw material flows and contacts each other fully.The moisture vaporizes rapidly.Liquid of0 raw material is dried into finished product in a short time.The finished product is discharged through cyclone separator at the bottom of dryer.The wasted air is exhausted through fan.

Features of LPG Series Centrifugal Spray Dryer

- Its dry speed is very fast.In general,it needs 5-15 seconds.It has feature of momentary dry.

- Material can be dried momentarily,it is suitable for drying thermal sensitive raw materials .It can maintain color,smell and taste of materials.

- Production process is simplify.Its operation and control is very convenient It is easy to continuous controlled production.

- The distribution,fluidity and solubility of product are good.

Particle size control. Steam heating or electric heating method. Movable liquid without any viscidity.

Regulation and control is very convenient. Purity and quality of products output are excellent. Stable and simple.

Commonly used in the food, pharmaceutical and chemical industries. Known for its high efficiency and reliability.

Rapid evaporation moisture and efficient drying products. Precise temperature control system. Easier installation.

Energy-saving, low energy, high efficiency. Ensure products with high-quality and pre-commissioning.

Widely used in the production of micro particles powder. Made of 304 stainless steel material. Temperature controls adopts real-time.

Widely used in the liquid processing and drying industry. We are offerring customize machine upon request.

Advanced heat technology. Automated controls adjust drying parameters same time for consistent powder quality and energy savings.

- Our Factory

- Technical Parameters

| Model | Inlet Temperature (℃) | Outlet Temperature (℃) | Max.Evaporated Amount of Water (kg/h) | Driving Style of Centrifugal Nozzle | Max.Revolution (rpm) | Diameter of Atomizing Disk (mm) | Heat Source | Max.Power of Electric Heater(Kw) | Recovery Rate of Dry Powder (%) | Overal Dimensions (LxW×H)(m) |

| 5 | 140~350 self-control | 80~90 | 5 | compressed airdrive | 2500 | 50 | electricity | 9-18 | ≥98 | 1.8X0.93X2.2 |

| 25 | 25 | mechanical driven | 18000 | 120 | steam plus electrloity | 9-18 (45-72All electric) | ≥98 | 3X2.7X4.26 | ||

| 50 | 50 | 18000 | 120 | steam plus electricity oil coal fuel hot air furnacion | 36electric meke-up | ≥98 | 3.5X3.5X4.8 | |||

| 150 | 150 | 15000 | 150 | 72electric make-up | ≥98 | 5.5X4X7 | ||||

| 200~5000 | 200~5000 | ~8000 15000 | 180~240 | hot air furnace | ≥95 | decide in accordance with practical conditlon |

Note:the evaporated amount of molsture is related to characteristics of material also inlet and outlet temperature of hot air.When outlet temperature is 90℃,Its curve of molsture evaporation is shown in above.(for reference when you choose Model).With renew of products unceasingly,the relevantparameterswill be changed,forgive we won’tannounce In advance.

Drying Industries

Focusing on core industries such as chemicals, pharmaceuticals, and food, we provide mature and reliable customized drying solutions.

What is a Centrifugal Spray Dryer

In many industries today, you may find that drying has become a necessary processing step. Whether in the food, textile, or chemical sectors and so on, materials in these fields require drying to form the final product. The centrifugal spray dryer is the equipment designed to accomplish this drying step. It uses the principle of centrifugal force to separate moisture from the product through spraying. It is suitable for drying various liquid forms such as solutions and suspensions and can extract the powdered or granular solids. If your application demands precise specifications for finished particle size, density, or dryness level, the spray dryer is an ideal process.

If you’re seeking a reliable centrifugal spray dryer for your project, consider FANQUN. Our professional team and advanced technology deliver efficient product drying solutions.

How Does a Centrifugal Spray Dryer Work?

Centrifugal spray dryers operate based on the physical principle of centrifugal force. The liquid feed can be atomized into minute droplets with the effect of centrifugal force within a high speed centrifugal atomizer. The moisture on the surface of these droplets rapidly contacts and evaporates with the hot air entering the drying tower, transforming the liquid feed into dry solid particles. After the completion of the drying process, the humid air is finally discharged through an exhaust fan.

The Main Components of a Centrifugal Spray Dryer

Feed Tank

The liquid storage tank serves as the reservoir for the material solution requiring drying. During machine operation, the solution is pumped from this tank into the high speed centrifugal atomizer positioned above the drying chamber, where the drying process is carried out.

Air Heating and Filtration System

The air heating and filtration system is where air enters the machine for heating and filtration. After this process, our heated air will enter the drying chamber and comes into contact with atomized droplets, facilitating moisture evaporation.

Drying Chamber

Within the centrifugal atomizer at the top of the drying chamber, the feed liquid is spun by centrifugal force into an extremely fine mist of droplets. This mist enters the drying chamber where it comes into contact with hot air for an extremely brief period. Under high temperatures, the moisture rapidly evaporates into steam, thereby achieving the drying of the raw material.

Cyclone Separator

Once the raw material is dried, a cyclone separator is required to separate the resulting solids from the gases, then you will get the desired dry solid powder.

Exhaust System

Finally, the exhaust system’s function is to expel the final moist air from the machine.

What are the Advantages of Using a Centrifugal Spray Dryer?

Faster Drying Speed

Compared to other types of spray dryers, it can rapidly dry the liquids into powder, this is a process that can be completed in a few seconds. The atomization process increases the contact area between moisture and hot air, enabling rapid evaporation and removal of water, thereby boosting the producing efficiency.

Simplify The Operating Process

It can produce high purity powdered finished products in a single step, reducing the need for additional grinding or screening operations, this also offers significant operational convenience.

Can Work Continuously

A centrifugal spray dryer enables continuous operation, it can automatically perform uninterrupted drying of materials and liquids. This is a crucial feature in industries such as food processing and chemical manufacturing to ensure consistent production efficiency and product quality. Moreover, you needn’t worry about energy consumption during this process. Compared to intermittent operation that requires preheating each time the machine is started, continuous operation is actually more energy efficient.

Can Deal With Materials That Are Sensitive To Heat

Due to the rapid evaporation characteristic of centrifugal spray dryers, your raw materials experience very brief contact with high temperature air. This is crucial for drying heat sensitive materials, as prolonged exposure to high temperatures could cause denaturation, while this brief contact minimizes the significant adverse effects.

The applications of a Centrifugal Spray Dryer

Textile industry

In the textile industry, centrifugal spray dryers can be used to dry dyes, making them easier to store and transport while improving the dyeing uniformity.

Chemical industry

In the chemical industry, centrifugal spray dryers can process materials such as detergents, polymers, and catalysts. Taking catalysts as an example, they can transform these substances into porous spherical powder solids. This structure enhances their reactivity in chemical processes, enabling more complete reactions and improving processing efficiency.

Food industry

In the food sector that is highly relevant to people’s daily lives, centrifugal spray dryers efficiently dry common powdered foods such as coffee powder, milk powder, and seasonings. Food powders dried by this method achieve uniform particle size, dissolve easily, and eliminate the need for subsequent granulation operations, making them suitable for large-scale production.

Medical field

In the medical field, pharmaceuticals also rely on centrifugal spray dryers to produce uniformly sized, stable drug powders. These powders are subsequently used in tablet compression and capsule manufacturing, ensuring therapeutic efficacy.

Ceramics

In ceramic manufacturing, it can also dry common materials such as alumina and talc powder, ensuring the subsequent powder’s fine texture for easy mixing in sintered ceramics to form exquisite ceramic products.

Chinese Medicine

The high speed centrifugal spray drying apparatus for Chinese herbal extracts is a specialized centrifugal spray dryer designed for drying herbal extracts. It preserves the purity and medicinal properties of plant-based solutions during drying while preventing coking and degradation, ultimately producing uniformly textured, easily soluble powders.

All components of FANQUN ‘s ZLPG series herbal extract spray dryer are constructed from stainless steel. Equipped with a three stage purification system, the filtered air meets Class 100,000 clean room standards, achieving over 95% powder collection efficiency. Contact us immediately for a quote.

What are the Key Parameters that Need to be Monitored During the Spray Drying Process?

During formal operation, you must also monitor certain parameters to verify the machine’s operational status. These may include the temperature difference between intake and exhaust air, the feed rate, etc.

Inlet And Outlet Temperatures

First, you need to monitor the temperature difference between the inlet and outlet air. This indicates whether the dryer is functioning properly. If the temperature difference exceeds the normal operating range compared to usual conditions, it may indicate insufficient drying of the material or overheating causing gelatinization. In such cases, you should immediately shut down the machine for inspection.

Feed Rate

During operation, you also need to ensure the feeding process remains constant and steady. Overfeeding can result in insufficient drying of the material, while underfeeding may lead to reduced production capacity and energy waste. Therefore, when initiating spraying, we recommend gradually increasing the feed flow rate from low to high. This ensures smooth and orderly material delivery while preventing wall adhesion.

Atomizer Speed

The atomizer’s speed is a key parameter that directly affects the droplet size. The rotational speed of its disk determines the fineness of the droplets, for example, higher speeds produce smaller droplets and finer powder. It is important to note that the disk speed must be matched to the feed rate; otherwise, uneven atomization may occur.

How to choose a proper Centrifugal Spray Dryer?

Particle size requirements

When making your selection, the required particle size is a fundamental factor to consider. If you require a dried product with finer particles, a high speed centrifugal spray dryer will better meet your needs. On the other hand, if you require a powder product with larger particles, a low speed spray dryer can achieve satisfactory results.

Material Heat Sensitivity

Depending on the heat sensitivity of the material you need to dry, you must also carefully select the centrifugal spray dryer. For example, plant extracts in the pharmaceutical field and catalysts in the chemical industry may not tolerate high temperatures. Therefore, you need to pay attention to the type of heating system to achieve a lower inlet air temperature.

Production Scale

You should also select based on your specific processing requirements. If the location where you need to use the dryer is a large factory, you may require a centrifugal spray dryer with a higher drying capacity. If you are selecting a laboratory or small to medium sized facility, a smaller unit may be more suitable for your application.

FANQUN is a long established enterprise in China’s drying industry. We boast a team of technical professionals with over forty years of experience and extensive export expertise. Our factory uses state of the art production equipment to manufacture high quality machinery for you. In terms of service, we can develop specialized product design solutions tailored to your needs. Our after sales support includes on site guidance for equipment installation and commissioning, as well as technical training, ensuring you have complete peace of mind.

When using a centrifugal spray dryer, you may encounter these issues: If you notice uneven particle size in the produced powder, you can resolve it by inspecting the atomizer’s wear condition and adjusting the atomization disc speed and feed flow rate.

If agglomeration or clumping occurs, this may result from excessively high inlet air temperature or inadequate atomization. Prompt adjustments are necessary.

Then, if you find that the production output decreases, this could indicate clogging of the filter screen or cyclone separator. Immediately shut down the machine for cleaning and establish consistent, proper operating practices during routine use.

Centrifugal spray dryers can process a wide range of materials, covering substances commonly used across numerous industrial sectors. These include materials frequently found in the food industry such as milk powder, coffee powder, and instant tea beverages; materials required in the ceramics industry like alumina, magnesium oxide, and talcum powder; as well as substances used in the plastics industry such as ABS, polyethylene, and polyvinyl chloride. This list is inclusive but not exhaustive.

Just like other types of machinery, maintaining a centrifugal spray dryer also relies on proper operating practices. After shutdown, you need to promptly clean the cyclone separator and feed liquid pipelines to prevent clogging from dried residue. Regularly inspection of the wear condition of components such as the atomizer nozzles and ensuring all other parts are in good working order are important, too. These measures help prevent and resolve issues in a timely manner, extending the service life of your equipment.

Before use, you must ensure the machine is placed in a well ventilated environment, as the equipment inevitably generates high temperatures during operation. Its working nature requires contact with various types of materials and liquids, which may produce significant dust. Additionally, grounding must not be omitted, this is a critical safety measure. In emergencies, it enables immediate disconnection protection to prevent sudden accidents such as dust explosions.