Features of Rotary Kiln Dryer

The FANQUN rotary kiln dryer dries your materials through the heat conduction technology inside the kiln body, which is both highly efficient and easy to operate. Order now and choose the FANQUN solution that suits you best!

- It is suitable for processing difficult-to-dry materials such as high-moisture and high-viscosity pastes and blocks.

- It has a strong single-machine large scale processing capacity and can achieve industrial-grade continuous large scale production.

- While drying, heat treatment processes such as calcination and decomposition can be completed.

- The mechanical structure is sturdy and can operate stably for a long time, adapting to harsh working conditions.

- The materials are constantly being turned over, which ensures good uniformity.

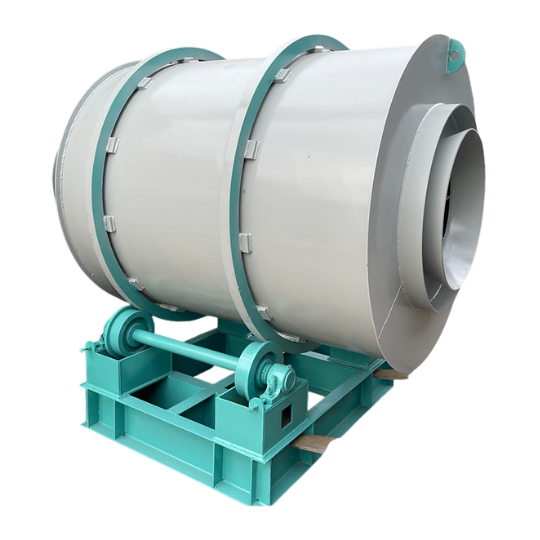

HG Series Rotary Kiln Dryer

Wet material is loaded from one head of the dryer, and then it is stirred by the bafflers that is uniformly distributed in the barrel. Material is uniformly distributed and dispersed in the dryer, fully contact the hot air of parallel (or counter) flow, so the drying process is expedited, and the impulsion power of media transfer is enhanced. During the drying process, material is under the effect of angled baffler and hot air, moves to the star shape unloader that is at the other head of the dryer.

Features of HG Series Rotary Kiln Dryer

- The high motorization level of the barrel and the great production capacity.

- The small resistance of the material passes through the barrel, and the low power consumption.

- The high adaptation to different characters of materials.

- The stable operation, the low operation fee, and the good uniformity of product drying.

Applications of HG Series Rotary Kiln Dryer

- Applicable for drying big particles, heavy particles in chemical, mining, and metallurgy, such as mining area, cinder of blast furnace, coal, powder of metal, phosphate fertilizer and thiamine.

- For drying the powder or particles with special requirements, such as HP foaming blowing agent, residue of alcohol, light calcium carbonate, active clay, magnetic powder, graphite, and residue of medicine.

- For materials to be dried under low temperature and large lot continuous production.

Has various industrial application and versatile heat source with energy controlled process, Advantages includes professional

Manufactured to have an excellent energy saving feature that also improved the drying process for different types of materials.

Ideal application for sand drying with multiple drums for thorough evaporation of damp sand, leaving no moisture build-up.

Commonly used to dry coal, An easy to operate rotating kiln with wide applications that supports both chemical and dry food production.

This equipment is manufactured with low consumption and high efficiency, the heating source is versatile.

The kiln is manufactured for application for energy or mining industries, longer lifespan and heat is various that includes oil or coal.

Great heat drying for sand or sawdust, It involves food production or agricultural materials.

Commonly used in chemical production and uses electricity for heating methods with features largely on production capacity.

- Our Factory

- Technical Parameters

| Item | Form | direct heating clockwise flow spec | direct heating clockwise flow spec | heat directly countercurrent spec | heat directly countercurrent spec | complex heat |

| Kinds of raw material | ore | vesicoant | cinder of blast furnace | ammonium sulfate | phosphorus fertilizer | coal |

| Amount to be treated (Kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Primary moisture (%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final moisture (%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| Average diameter (mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Bulk density of raw material (kg/m³) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Amount of hot air (kg/h) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Temperature of air at inlet (℃) | 600 | 165 | 500 | 180 | 650 | 570 |

| Temperature of raw material at outlet (℃) | 42 | 100 | 70 | 80 | 75 | |

| Way of heating | gas | steam or electric heating | heavy oil | coal fuel hot furnace | heavy oil | heavy oil |

| Loading efficiency (%) | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Revolution (rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Gradient (mm) | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Quantity of stirring-up rake | 12 | 24 | 12 | 22 | 16 out of cylinder, 6 in cylinder | 6, 12 |

| Diameter of dryer (m) | 2.0 | 1.5 | 2 | 2.3 | 0.84 out cylinder, 2 in cylinder | 2.4 out, 0.95 in |

| Length of dryer (m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power (kw) | 22 | 7.5 | 15 | 11 | 11 | 16 |

What is a Rotary Kiln Dryer?

The FANQUN rotary kiln dryer is a large-scale equipment that uses a low-speed rotating inclined drum to dry your materials.

Usually, wet materials are repeatedly lifted and scattered inside the cylinder, fully contacting the counter-current or co-current hot air flow, which will cause the moisture to evaporate rapidly. Its core features are large processing capacity and strong adaptability, which is especially suitable for handling sticky and wet filter cakes, granular and blocky materials such as minerals, chemical products, and municipal sludge.

The Working Principle of the Rotary Kiln Dryer

- Step 1: Wet materials are continuously and stably fed into the interior of the rotary kiln dryer cylinder. Special rakes are installed on the inner wall of the cylinder. As the cylinder rotates, these rakes continuously lift your materials, evenly distributing them across the cross-section of the cylinder and increasing the contact area with the hot air.

- Step 2: The high-temperature hot air flow comes into full direct or indirect contact with the wet material particles. Heat is rapidly transferred to your materials through convection and conduction, enabling the moisture on their surfaces and inside to gain energy and vaporize, and the water vapor is carried away by the hot air flow.

- Step 3: Under the combined effect of gravity and the slight inclination of the cylinder, the material that has been turned over and gradually dried moves slowly towards the discharge port. This movement process ensures that your materials stay long enough and are dried evenly and thoroughly.

- Step 4: When the material is moved to the discharge port, its moisture content has dropped to your requirement and can be discharged and collected through the discharge device. The low-temperature exhaust gas carrying a large amount of water vapor and a small amount of dust is discharged and enters the subsequent dust removal and purification system for treatment. It is only discharged after meeting the standards.

Features and Advantages of FANQUN Rotary Kiln Dryer

Strong Adaptability

The FANQUN rotary kiln dryer can not only efficiently process common granular and block materials, but also handle municipal sludge, chemical slurry and other materials with high water content and high viscosity. Through the lifting plates inside the cylinder, these sticky and wet materials can be crushed and lifted, achieving uniform drying.

Large-Scale Processing Capacity

As a heavy-duty continuous equipment, our rotary kiln dryer has a large processing capacity and stable operation. Its cylinder can be designed according to your requirements, with a diameter of several meters and a length of tens of meters. It can handle materials ranging from tens to hundreds of tons per hour for you, which makes it highly suitable for industrial fields such as mining, metallurgy, and large-scale chemical industries that require large-scale continuous production.

Drying and Heat Treatment Functions

Our rotary kiln dryer can not only achieve simple dehydration and drying, but you can also control its high-temperature environment and longer material residence time, which enables it to complete light calcination or chemical reaction processes while drying. This characteristic not only simplifies the process flow but also gives it a unique advantage in the treatment of inorganic salts, minerals, catalysts and other materials.

Stable and Reliable Operation

Due to its sturdy mechanical structure and relatively simple working principle, the FANQUN rotary kiln dryer can achieve long-term and highly reliable continuous operation under correct maintenance, which has strong tolerance to fluctuations in working conditions and has a long service life.

Operational Flexibility

You can conveniently adjust the final moisture content and output of your materials within a certain range by changing the rotational speed, inclination angle or hot air parameters of the rotary kiln dryer to meet different production requirements.

Heat Source Adaptability

Our rotary kiln dryer has a strong adaptability to various types of heat sources. You can flexibly choose natural gas, coal, fuel oil, biomass fuel, or even utilize process waste heat or residual heat according to the on-site conditions.

Applications of Rotary Kiln Dryers

Mineral Industry

Our rotary kiln dryer is highly efficient in drying ores, clays, bentonite, limestone, etc. It not only reduces transportation and grinding costs but also seamlessly integrates with subsequent calcination or sintering processes, which provides you with stable and qualified dried raw materials.

Chemical Engineering Field

Rotary kiln dryers are often used for drying inorganic salts such as calcium carbonate and magnesium hydroxide, as well as for drying chemical fertilizer products like ammonium phosphate and compound fertilizers after granulation. Its moderate drying intensity can not only effectively dehydrate but also maintain the integrity of the particles, making it an important piece of equipment in many continuous chemical production lines.

Sludge Treatment

The FANQUN rotary kiln dryer can stably dry the sticky and wet sludge with a moisture content as high as 80% to 10%-40%, making the sludge meet the requirements for subsequent incineration power generation, building materials utilization or landfill, which achieves harmless and resourceful disposal of sludge.

Agriculture Field

High-moisture agricultural by-products and biomass such as distiller’s grains, soybean meal, straw and sawdust can be dried by rotary kiln dryers. The dried products can be used as raw materials for high-quality feed or biomass fuel. Drying has effectively enhanced the utilization value of these resources and promoted the development of a circular economy.

FANQUN, as a well-known enterprise in China’s drying industry, is committed to the research and development of drying, pharmaceutical, chemical, food and other equipment. It is one of the largest drying equipment manufacturers in China with the most complete product range and the highest quality.

The FANQUN rotary kiln dryer enables wet materials to evaporate moisture through heat conduction in a low-speed rotating kiln body, which is both highly efficient and has the capacity for large-scale processing. If you need a rotary kiln dryer, FANQUN is your ideal choice.

If you have any other questions about FANQUN dryers, please feel free to contact us at any time.

Our core components adopt heavy-duty design and wear-resistant materials. The key transmission system is equipped with long-lasting lubrication. The structure is sturdy and reliable, which can ensure long-term continuous operation and significantly reduce your long-term comprehensive maintenance costs.

We have significantly improved the thermal efficiency by optimizing the kiln body insulation, hot air circulation and waste heat recovery system of exhaust gas. While processing high-moisture materials, it achieves lower unit energy consumption than traditional rotary kilns.

By adjusting the rotational speed, inclination angle, hot air temperature and internal raking, our equipment can flexibly adapt to the changes in the moisture content, viscosity and particle size of your materials within a certain range, which ensures the continuity and stability of your production line.

Our equipment is equipped with mature dust removal, dehumidification and exhaust gas purification systems. The dust emission concentration and other indicators can all meet the strict domestic and international environmental protection standards. At the same time, we also provide customized solutions.

Our rotary kiln dryer is equipped with an intelligent PLC control system, allowing you to achieve fully automatic interlocking adjustment of temperature, rotational speed, air volume and feed volume. In addition, it also supports remote monitoring and data traceability, which can significantly reduce human errors and labor costs.