A vast majority of the solid products you use, ranging from pharmaceutical drugs to fertilizers, are produced with the help of rotary dryers.

These handy systems have been a mainstay across multiple industries, where they are primarily used to extract moisture from pasty products or at least reduce their moisture content. But how do they achieve this? Here are the answers you need.

What is a Rotary Dryer?

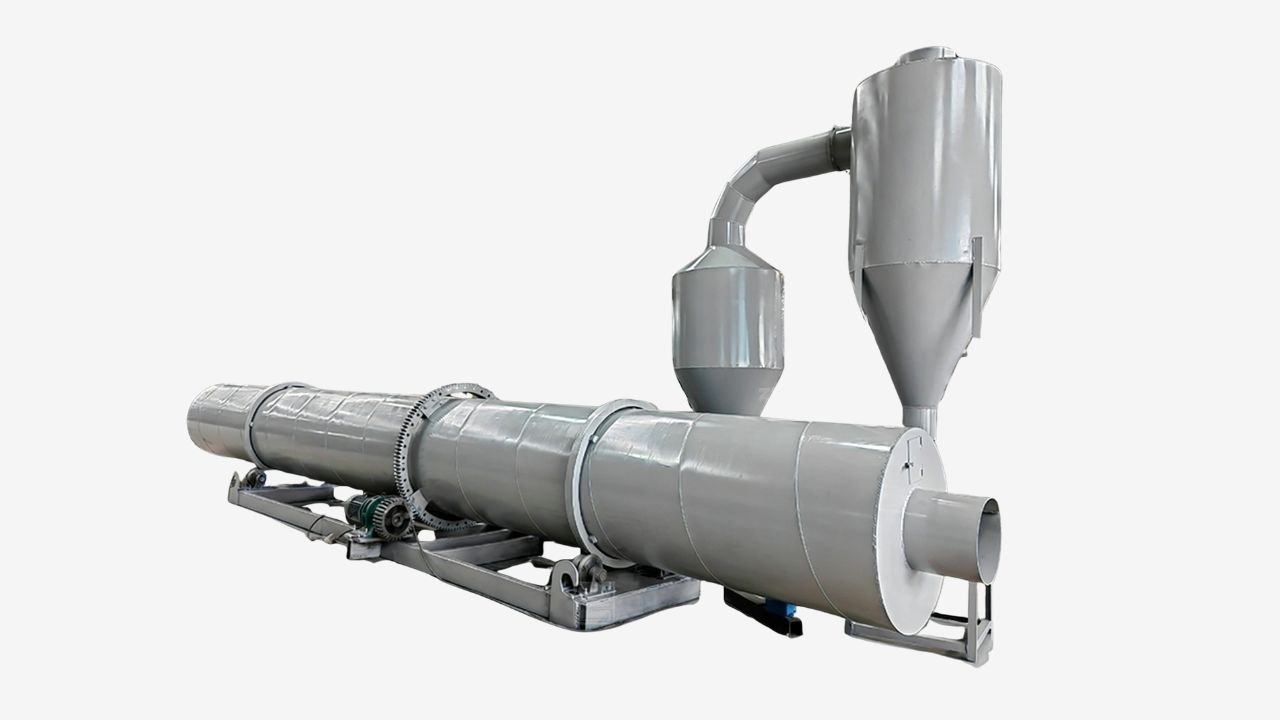

A rotary dryer is a unique drying machine that is essentially a large revolving drum that dries varying materials such as minerals and chemicals by bringing them into contact with the heated walls of the drum. This continuous yet controlled heating forces the solvent in the feed material to evaporate, leaving you with solid or powdered products.

Parts of a Rotary Dryer and Their Respective Roles

To fully grasp how a rotary dryer works, you must first gain a clear understanding of the distinct parts that make it a functional and efficient drying machine. These parts include:

| Rotary Drier Parts | Function |

| Rotating Cylinder | A large stainless steel tube tasked with rotating your wet products as it dries them. |

| Support Structure | Sturdy frame or posts that hold the rotating cylinder. |

| Heat Source | Generates the heat required to evaporate the moisture or solvent in your wet products. |

| Drive Mechanism | Typically, a motor system tasked with providing the power needed to spin the rotating cylinder continuously. |

| Feed System | An inlet system that allows you to inject your wet product into the rotary drying machine. |

| Internal Flights | Metal fins found on the drum’s inner wall, and tasked with agitating the feed material. |

| Discharge System | Provide an exit route for your dried product, often delivering them to a connected packaging system. |

| Exhaust System | Gets rid of the vaporized solvents generated once heat is applied to the wet material. |

Rotary Dryer Working Principles

Rotary drum driers simply generate dried or powdered products, such as fertilizers and minerals, by extracting the solvent in them via evaporation. They exploit numerous heat exchange principles, key amongst them being:

· Convection

Most rotary driers rely on convection to transfer heat onto the feed material, prompting evaporation. Hot gas is introduced into the rotary drum, where it comes into contact with your feed material. Heat is then transferred to the particles of your material, leading to rapid evaporation. The hot air also acts as a carrier of the extracted moisture, leaving you with solid or powdered goods.

· Conduction

Conduction is mainly exploited by indirect rotary drum driers, which dry your pasty products by heating them once they come into contact with the rotating drum. Once your inlet feed is introduced, it is distributed along the rotating cylinder, whose inner walls are heated. Once the material comes into contact with the heated walls, the held solvent vaporizes and is subsequently discharged from the machine via an exhaust system.

· Evaporation

Rotary driers simply produce powdered or solid goods by removing the solvent (e.g., water) through evaporation. They apply heat to the wet product directly or indirectly, forcing the solvent to vaporize. The vapor is then disposed off, leaving you with dried products.

· Mechanical Agitation

The material driven into the rotary cylinder is continuously rotated while the lifting flights agitate the material as it dries. This ensures that heat is distributed evenly across the wet material and also keeps the material from sticking to the walls of the rotary drum.

Step-by-step How a Rotary Dryer Works

Whereas the operation of rotary dryers boils down to evaporation, the process is slightly more complicated. The application of heat must be carefully controlled to avoid damaging the feed material or messing with its structural integrity. Here are the steps that come into play;

· Introduction of the Wet Material

The material to be dried is injected into the rotary dryer through the inlet feed, which is typically located at the raised end of the rotary drum. This can be done manually or automatically with the help of an infeed conveyor. The feed is introduced continuously, and it spreads around the inner walls of the drum via gravity.

· Drum Rotation

The introduced material is subsequently distributed around the rotary cylinder, where it comes into contact with the inner walls. The rotating cylinder ensures that the heat is uniformly distributed across the material, leading to consistent drying. The rotating motion is driven by motors connected to the rotary cylinder.

· Cascading Action

As the wet material spins around in the rotary drum, the lifting flights installed on the drum’s inner wall open and close, constantly agitating the material. First, they open, subsequently lifting the feed material and exposing it to a stream of hot gas. This ensures uniform drying and keeps your product from sticking to the inner walls.

· Direct Heating

In direct rotary drum driers, a stream of hot air or gas is introduced into the rotating cylinder holding your feed material. The hot gas interacts with the wet material directly, leading to the transfer of heat. Once the material is adequately heated, the harbored solvent turns into vapor, which is subsequently discharged from the material. This greatly shrinks the material’s moisture content, leaving you with powdered products or solid goods.

· Indirect Heating

Indirect rotary drum driers get rid of the moisture in the feed material without subjecting the material to direct heat. Instead, they rely on heated walls to provoke evaporation. The walls are typically heated using steam, and heat is consequently transferred to the wet material via conduction. These dryers are preferred when drying products that are quite sensitive to heat or can be easily contaminated by the application of hot gases.

· Airflow Direction

In rotary dryers reliant on hot gases, these gases can assume either co-current flow or counter-current flow. The latter sees the hot air flow in the opposite direction to the flow of your feed material. In co-current flow driers, the hot gas, conversely, flows in the direction your feed material flows. That is from top to bottom, leading to rapid evaporation.

· Moisture Extraction

After the material has been subjected to heat, the solvents in the material turn into vapor, which is consequently ejected from the rotary drum via a dedicated exhaust system. This exhaust system often comes with filters, which ensure that only unwanted solvents are extracted from your feed product.

· Discharge

Moisture is driven out of the feed material continuously as it flows down the rotary cylinder. Once it reaches the inclined end of the drum, it is driven out of the rotary dryer and ferried to the next production stage. At this point, its moisture content is deemed desirable.

FAQs

What are the Advantages of Rotary Dryers?

Rotary dryers come with a myriad of benefits, hence they feature prominently in most production facilities. They boast a high evaporation rate ranging between 30 and 70 kg/(m.h) and a high thermal efficiency of up to 90%.

What is the Operating Temperature of Rotary Dryers?

The operating temperature of rotary dryers depends on the type of product being dried. However, most dryers operate at temperatures ranging between 90°C and 1200°C.

What is a Rotary Dryer Used for?

Rotary dryers are primarily tasked with helping you shrink the solvent content in your wet products, consequently generating dry or powdered goods such as fertilizer and various minerals.

What Issues Are Common in Rotary Drum Dryers?

Rotary drum dryers remain one of the most heavily utilized drying machines thanks to the myriad of rewards they promise. However, they are not devoid of limitations such as mechanical stress and material constraints.

How Long Does it take a Rotary Dryer to Dry Wet Material?

Different materials have different moisture content, and this means that they need different residence times to dry. However, for most materials, the drying time ranges between 30 minutes and 2 hours. When setting your rotary dryer, ensure that you get the drying time right to avoid damaging your feed material.

FanQun is your Trusted Rotary Dryer Manufacturer in China

At FanQun, we customize every rotary dryer machine to meet the specific drying requirements of our clients. With every dryer, we optimize performance variable to ensure your final products have the right moisture content.

Therefore, if you are looking for a rotary dryer manufacturer you can trust in China, FanQun is your trusted partner – contact our sales team now.