Features of Rotary Drum Dryer

FANQUN rotary drum dryer has a large-scale drying processing capacity and is suitable for a variety of industrial applications. Order now and choose the FANQUN solution that suits you best!

- High-strength materials and reinforced rollers are adopted to ensure long-term continuous operation.

- The large drum volume and continuous feeding and discharging design make it suitable for large-scale industrial production.

- Flexibly adjust the rotational speed, temperature and inclination angle to meet the drying requirements of different materials.

- It features a high degree of automation, ensuring stable and low-failure-rate operation throughout the year without interruption.

- Equipped with a dust removal system, it meets environmental protection requirements and enables product recycling.

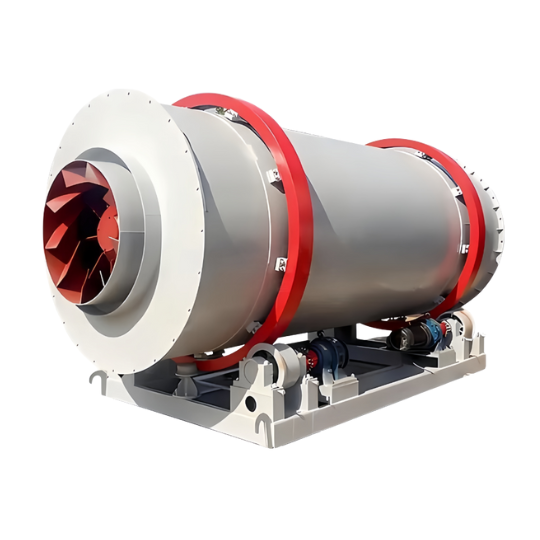

HZG Series Rotary Drum Dryer

The machine is mainly used in per tuning of rigid magnet oxygen pulverized powder. It is also suitable for the cement, metallurgy and chemical industry. It is consisted of main kiln body,supporting drive set cooling pipe, oil fuel system,electricity control,secondary air inlet set,exhaust dust set and warm-up kiln body etc.Main function of this dryer includes over temperature,over loading,auto control for working temperature,oxygen atmosphere is adjustable in the kiln etc.

Principle of HZG Series Rotary Drum Dryer

Wet material is loaded from one head of the dryer, and then it is stirred by the balliers that is uniformly distributed in the barrel.Material is uniformly distributed and dispersed in the dryer,fully contact the hot air in parallel for counterflows to the drying process is expedited and the impulsion power of media transfer is enhanced.During the drying process,material is under the effect of angled buffer and hot air and moves to the rotary valve that is at the other head of the dryer.

Features of HZG Series Rotary Drum Dryer

- The mechanical level content of rotating dryer is high and its productive capacity is large.

- Because the resistance when fluid passes through the cylinder is small,the consumption of power is low.

- Have strong adoptability to raw materials.

- Its operation is stability and the cost of operation is cheap.The homogeneity of dried product is good.

Application of HZG Series Rotary Drum Dryer

- Applicable for drying big particles,heavy particles in the field of chemical mining and metallurgical industry. For example:slag of blast furnace,cool,metallic powder,phosphorus fertilizer,thiamin and so on.

- For drying powder,grannite raw materials which have special requirements such as:HP vesicant,lees,preeplinated calcium carbonate,actived clay,magnetic powder,graphite,and residue medical and so on.

- For materials to be dried under low temperature and large production in line.

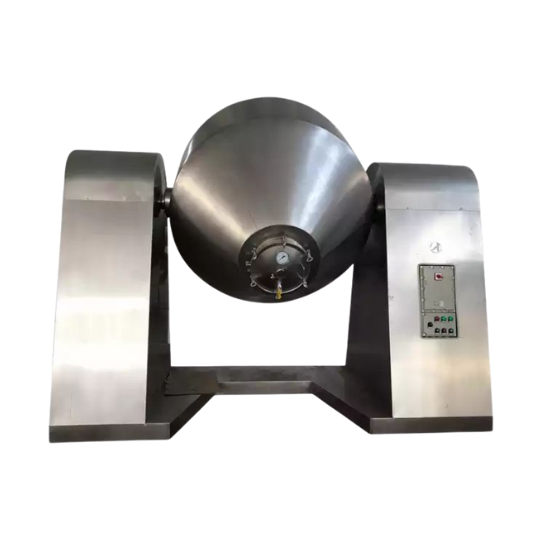

Auto chemical and food processing that has a dual cone mixer method. Non-stick interior design for easy clean.

Steam heating rotary with adjustable drying efficiency and wide application from food processing to pharmaceutical products.

Electric-powered vacuum dryer with easy to operate manual and environmental friendly control.

Great usage for dry grains and has energy-efficiency, large output and is high-quality. Simple operation and automatic temperature control.

Energy-efficient control and has a large capacity, Multiple heating methods and application. Sand drying application.

One of the commonly used for sawdust or wastes with less environmental usage, The design ensures air dry and client satisfaction.

Dries grains with high temperature and the speed of the drum is adjustable and evaporates moisture faster.

Great temperature control and has multiple heating sources that can ensure continuous rotation.

- Our Factory

- Technical Parameters

| Model | Direct heating co-current type | Direct heating co-current type | Direct heating counter-current type | Direct heating counter-current type | Compound heating | Compound heating |

| Kinds of raw material | Geo | HP vesicant | Feature | Feature | Feature | Feature |

| Amount to be treated(g/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Primary moisture(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final moisture(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| Average diameter(mm) | 6.5 | 0.05 | 4.7 | 0.5–1.7 | 0.5 | 5 |

| Bulk density of raw material(g/hr) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Amount of hot air(g/h) | 39000 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Temperature of air inlet(℃) | 600 | 165 | 500 | 180 | 550 | 570 |

| Temperature of raw material outlet(℃) | 42 | 100 | 70 | 80 | 75 | 75 |

| Way of heating | Gas | Steam electric heating | Heavy oil | Coal fuel hot air furnace | Heavy oil | Heavy oil |

| loading efficiency(%) | 6.3 | 7 | 7.5 | 7.8 | 18 | 2 |

| Revolutions(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Diameter of dryer(m) | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Length of dryer(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

What is a Rotary Drum Dryer?

FANQUN rotary drum dryer is an industrial drying equipment.

Wet materials enter from the high end and are repeatedly lifted and scattered as the drum rotates. Meanwhile, hot air passes through the drum, conducting thorough heat exchange with your materials, causing the moisture to evaporate rapidly. During this process, the material moves towards the lower end under the action of gravity and completes the drying process, and is finally discharged from the discharge end.

It is widely used in various industrial drying processes due to its large processing capacity, stable operation and wide adaptability.

The Working Principle of the Rotary Drum Dryer

- Step 1: Wet materials are continuously fed into the high end of the drum through the feeding device. As the drum rotates slowly, the materials at the bottom will be lifted and carried to a certain height.

- Step 2: Under the effect of its own gravity, the material is thrown off, forming a dispersed and uniform material curtain across the entire cross-section of the drum, which greatly increases the surface area of the material.

- Step 3: The hot air driven by the fan passes through the drum and thoroughly mixes and comes into contact with the falling material curtain. Heat is rapidly transferred from the hot air to the wet material, causing the surface moisture to evaporate and vaporize quickly.

- Step 4: The exhaust gas, which has completed heat exchange and carries a large amount of water vapor, is discharged from the drum exhaust system and then enters the subsequent dust removal system. After the fine dust carried is recovered, the clean gas is discharged into the atmosphere.

- Step 5: The dried material will be discharged from the bottom of the rotating drum desiccant, and you can then proceed to the next processing step.

The Features and Advantages of Rotary Drum Dryers

Cylinder Structure

The FANQUN rotary drum dryer is equipped with a long cylindrical drum. This structure ensures that the heat of your materials is evenly distributed during the drying process. In addition, our rotary drum dryers are available in both single-drum and double-drum configurations. You can choose the appropriate configuration according to your application and the scale of the material.

Continuous Feeding and Discharging

Our equipment adopts a mechanical feeding device to continuously feed wet materials from the high end, while the dried products are continuously and automatically discharged from the low end. It can efficiently handle your large quantities of materials and is perfectly adapted to industrial large-scale continuous production processes.

Sturdy Structure

The rotary drum dryer adopts high-strength materials and a reinforced drum structure. This solid mechanical construction endows the equipment with outstanding load-bearing capacity and fatigue resistance, enabling it to withstand heavy loads and achieve continuous and stable operation without interruption.

High-Efficiency Heat Transfer

The materials inside the drum are repeatedly lifted and scattered, causing a sharp increase in the surface area of the materials. This enables the high-temperature gas flow to have full and direct contact with the surface of the materials, which accelerates the efficiency of heat transfer and water vapor evaporation.

High-Efficiency Dust Removal

The exhaust gas produced after drying will enter the matching high-efficiency dust removal system, which can capture and separate the vast majority of dust carried in the exhaust gas, ensuring that the final emission meets environmental protection requirements and effectively recovering valuable products.

Operational Stability

Due to its robust mechanical structure and continuous working principle, the FANQUN rotary drum dryer can operate stably for a long time and handle a large amount of materials, making it particularly suitable for industrial scenarios that require large-scale drying.

Strong Adaptability

By adjusting parameters such as the drum speed, inclination, and hot air temperature, our rotary drum dryer can handle various materials, including granules, blocks, and filter cakes, with a large operational flexibility and a wide range of applications.

Uniformity of Drying

The materials are constantly scattered and mixed inside the cylinder, avoiding local overheating or uneven drying, thus ensuring that your final product has a good and consistent drying effect.

Applications of Rotary Drum Dryers

Mining and Building Materials Sector

FANQUN rotary drum dryers are often used for large-scale processing of raw materials such as ores, slag, clay, quartz sand and limestone. It can effectively remove the moisture from these materials to meet the subsequent processing procedures such as crushing, grinding or calcination, making it an ideal choice for drying materials in your production line.

Chemical Industry

Our equipment is widely used in the chemical industry, especially suitable for drying fertilizers, catalysts and various inorganic salts. Its operational stability and controllability ensure that these industrial products meet specific quality indicators such as crystallinity, moisture content and particle strength.

Agriculture Field

In agriculture, rotary drum dryers can be used to dry grains, feed and agricultural waste, etc., which is convenient for long-term storage and transportation.

Environmental Protection Field

Rotary drum dryers are indispensable equipment for sludge treatment. They can dry municipal or industrial sludge with high moisture content into granules, which can be used for incineration power generation, composting or utilization in building materials, achieving sludge reduction and resource recycling and reuse.

FANQUN, as a well-known enterprise in China’s drying industry, is committed to the research and development of drying, pharmaceutical, chemical, food and other equipment. It is one of the largest drying equipment manufacturers in China with the most complete product range and the highest quality.

The powerful drying processing capacity of the FANQUN rotary drum dryer enables your materials to achieve large-scale and completely thorough drying effects. If you need a rotary drum dryer, FANQUN is your ideal choice.

If you have any other questions about FANQUN dryers, please feel free to contact us at any time.

Our equipment is particularly suitable for handling large quantities of bulk granular materials, such as slag, fertilizers, feed, etc. In addition, some paste-like materials with certain viscosity can also be processed through customized techniques.

We offer fully automatic control system solutions, which can monitor and automatically adjust key parameters such as temperature, air volume and rotational speed in real time, which significantly reduces its reliance on you and human errors.

Sure. The rotational speed can be steplessly adjusted by the frequency converter. During installation, the inclination can be adjusted within a certain range through the gasket to control the residence time of the material in the cylinder and precisely control the drying degree of the material.

Our core load-bearing components are made of high-strength materials and undergo special heat treatment processes, featuring extremely high hardness and wear resistance on the surface. Meanwhile, we offer replaceable wear-resistant liners, which greatly extend the service life of the main body of the equipment.

By optimizing the insulation of the cylinder and adopting a waste heat recovery system for exhaust gas, we can effectively reduce the flue gas temperature, enhance the thermal efficiency of the system, which significantly lower your operating costs.