FANQUN Paddle Dryers

Benefiting from its unique hollow structure and uniform mixing capability, the paddle dryer delivers consistent and efficient drying for viscous, high-viscosity materials.

- The hollow structure of the paddle dryer enhances drying efficiency and energy efficiency.

- The paddle dryer possesses excellent self-cleaning capabilities.

- Jiangsu Fanqun Drying Equipment Factory possesses over 25 years of experience in paddle dryer production.

- Jiangsu Fanqun Drying Equipment Factory is IS09001 certified manufacturer

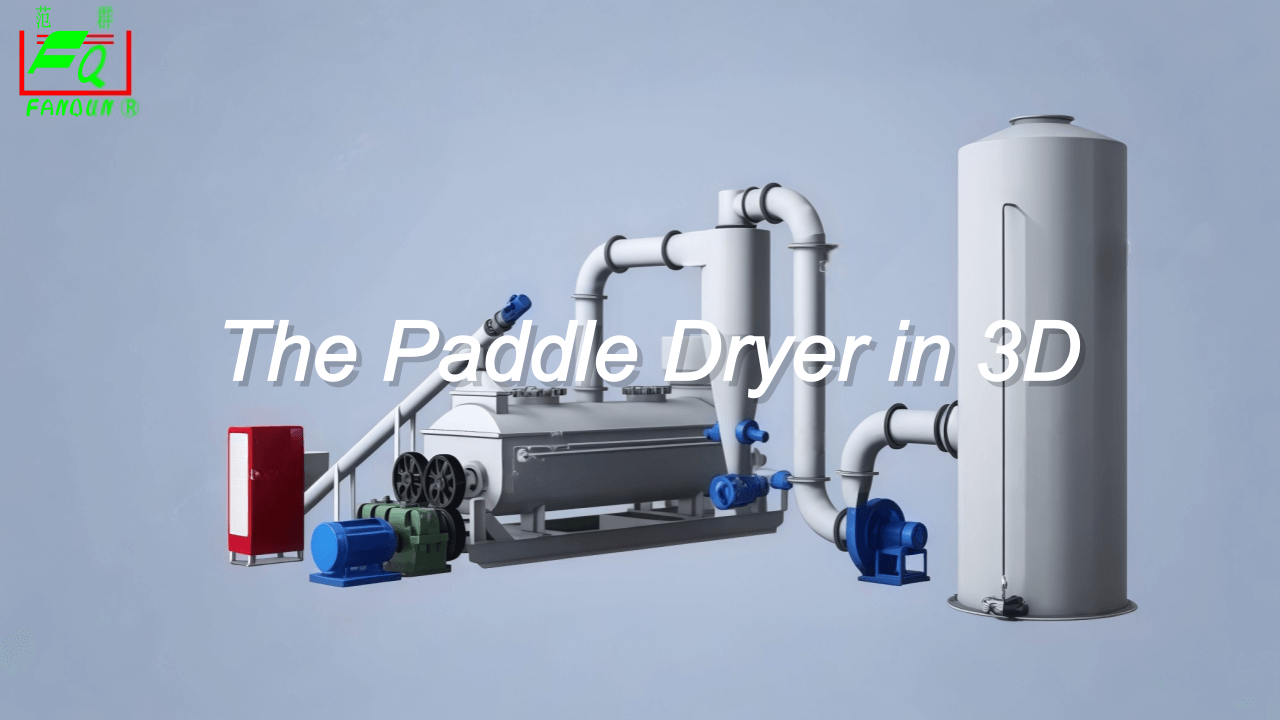

3D Structure & Airflow of FANQUN Paddle Dryer

This video shows the internal structure and heat transfer process of FANQUN paddle dryer. The rotating paddles continuously mix and convey material while heat is indirectly transferred through the paddles and jacket.This design ensures uniform drying, gentle material handling, and high thermal efficiency, making the paddle dryer ideal for drying sludge, paste, and heat-sensitive materials in continuous industrial applications.

What is the Paddle Dryer?

The paddle dryer is an industrial drying apparatus specifically designed for drying moist, viscous slurry-like materials such as sludge or pastes. It is a horizontally positioned, hollow-structured cylindrical unit equipped with agitation blades, heating elements, and a rotating shaft to achieve efficient drying. You may utilise it in industries such as the chemical and pharmaceutical industry, food production, and industrial wastewater treatment.

How does the Paddle Dryer work?

- Feeding the Material: Prior to commencing the drying process, you must place the moist material into the chamber of the paddle dryer.

- Agitating the Material: The rotating shaft drives the paddles to continuously stir the material, preventing the moist material from clumping or sticking together. Furthermore, during the heating process, the paddles continue to rotate to ensure more uniform heating.

- Heat Transfer: Heat transfer methods vary depending on the paddle dryer type. One method involves direct heat transfer, where hot gas contacts the material directly. The other employs indirect heat transfer, where hot gas transfers heat through a jacket and hollow paddles.

- Discharge of Finished Product: The material is continuously stirred to ensure even cooling. The paddle dryer discharges the dried material after complete drying.

JFQ-YQJ-ZK Paddle Dryer Series

The vacuum paddle dryer is used for the indirect heating and cooling of pasty, granular, powdered, and slurry materials. The disc-type paddles inside the equipment feature a large heat transfer area and high heat transfer efficiency.

The rotary vacuum paddle dryer features low dust generation during operation and high safety performance. The structure is compact, the overall dimensions are small, auxiliary equipment is minimal, and the system is simple.

Paddle Dryer Solutions by Application

High thermal efficiency, precise temperature control. Suitable for steam, water or oil as heading medium.

High safety level. Build with Stainless steel 304 / 316 materials. Easy operation and stability. ISO certified.

Ideal for temperature-sensitive material. Improved product quality due to low-temperatures drying system.

Applicable to slurry paste paste, powder materials. Adopts large area with large heat method.

Economical, robust multifunctional machine for industrial applications. Operation under vacuum and high pressure.

Easy to operate, low consumption high efficiency products. Materials usually graphite, carbide, and alloy.

Widely used in chemical and food processing. Energy-saving machine. We carefully design and produce with an experienced and skilled team.

Long service life. 220-415v voltage rating. Oil heating method. Easy to operate and control. Stainless steel and carbon steel material.

Full Project Support for Your Paddle Dryer

From material testing to long-term operation, we support your project at every stage.

We can provide you free material testing before order.By testing your material in advance, we help reduce technical risks, optimize paddle dryer configuration, and ensure stable operation under real production conditions.

What we evaluate during material testing:

- Initial and target moisture content

- Material viscosity and flow behavior

- Thermal sensitivity and drying temperature range

- Residence time requirements

- Suitable paddle dryer type and configuration

- Design Support: Customized engineering design based on material properties and capacity requirements.

- Installation & Commissioning: On-site guidance to ensure safe and efficient operation.

- Online Support: Remote technical support and troubleshooting throughout the equipment lifecycle.

- Spare Parts Supply: Long-term spare parts availability to reduce downtime.

- Warranty: One-year warranty for reliable and stable operation.

- Our Factory

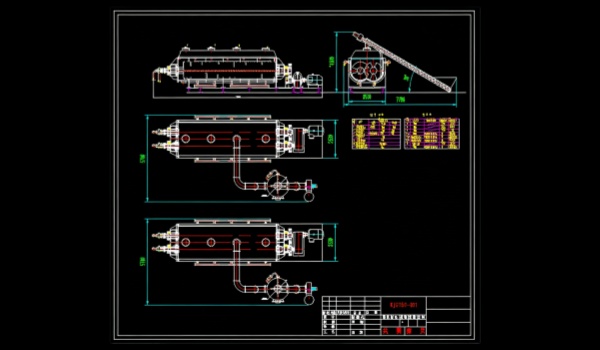

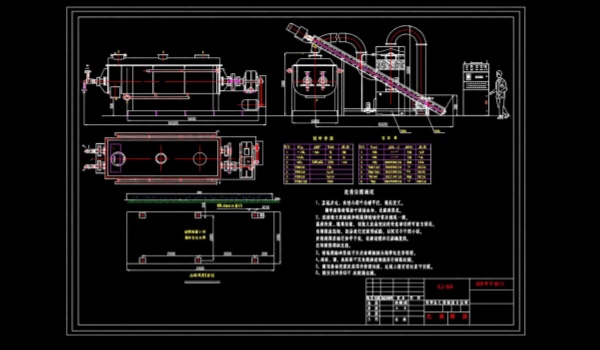

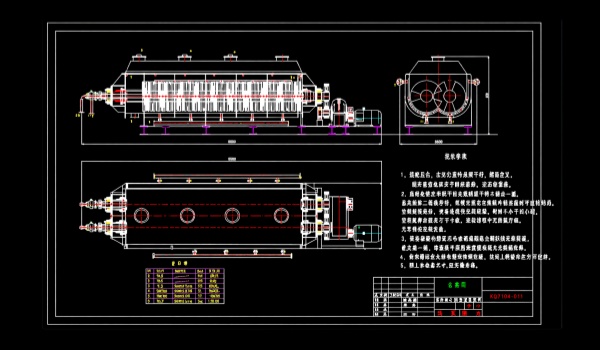

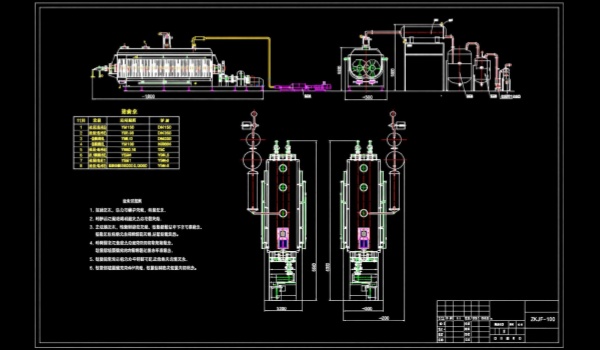

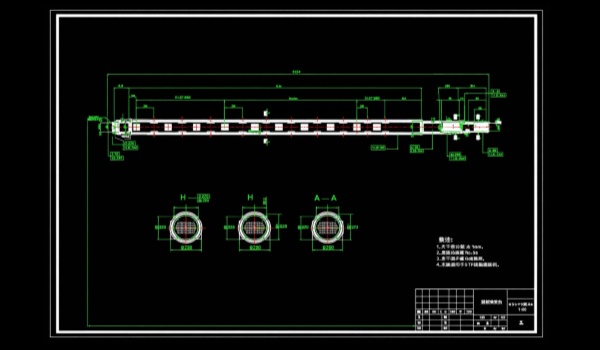

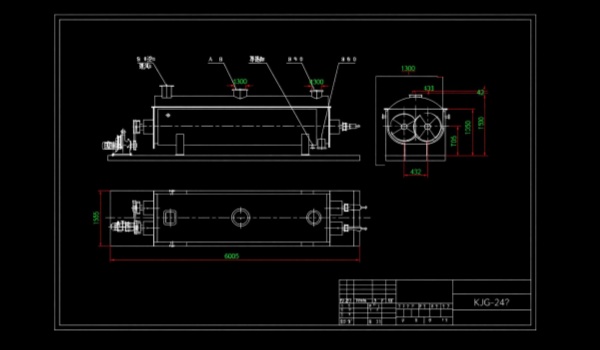

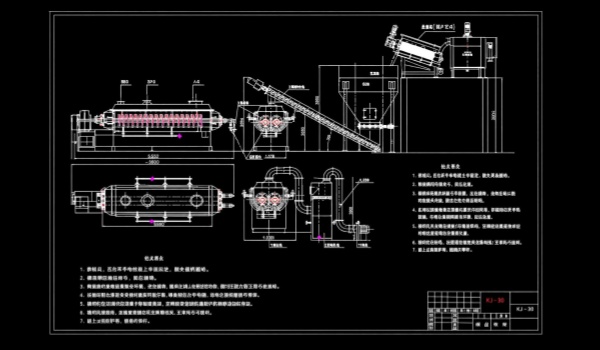

- Engineering Drawings

Customer Feedback from Real Projects

Applications by Material Type

Helping you quickly identify the right paddle dryer for your specific material and process.

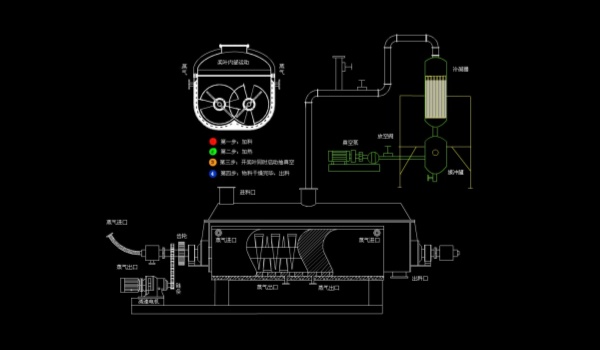

Components of the Paddle Dryer

Heat Transfer and Agitation System

- Rotary shaft: The rotating shaft of the paddle dryer drives the paddles to agitate the material during the drying process. It is typically hollow, allowing hot gas or other heat transfer media to pass through the shaft, thereby transferring heat to the material.

- Paddles: The paddles come into direct contact with the material during stirring. Consequently, they are also designed with a hollow structure to facilitate the flow of hot gas, enhancing drying efficiency. The rotation of the paddles ensures uniform drying of the material. Additionally, their wedge-shaped design achieves a self-cleaning effect, preventing material adhesion and clumping on the blades.

- Housing: The casing of the paddle dryer protects the internal components. It contains the material and features a sealed design. It is also hollow to increase the heat contact area and prevent direct thermal damage to the material.

Power and Fuel

- Motor: The motor serves as the primary power source for the paddle dryer, enabling high-torque rotation of the paddles to ensure efficient drying.

- Fuel: Heat for paddle dryers is primarily generated through thermal oil, hot water or steam. Additionally, to support environmental sustainability, some paddle dryers utilise biomass for heating.

Sealing Structure

To prevent heat and material leakage, paddle dryers incorporate sealing mechanisms. Furthermore, sealing is essential for vacuum paddle dryers to prevent disruption of the vacuum environment.

Emissions Control

Moisture emitted within the paddle dryer must be promptly discharged; otherwise, drying efficiency will diminish. The discharge system incorporates a condenser and cyclone separator to prevent material wastage and achieve efficient emissions, thereby ensuring stable equipment performance.

Feed and Discharge Apparatus

Material may be introduced into the paddle dryer via its hopper, with the dried product discharged from the rear end of the unit. This is typically equipped with a rotary airlock valve or other separation device to ensure stable discharge.

Types of Paddle Dryer

Direct and Indirect Paddle Dryers

- Direct Paddle Dryer: The heated gas produced by the direct paddle dryer’s heating system enters the chamber directly to contact the moist material, evaporating the moisture within for drying.

- Indirect Paddle Dryer: The vessel walls and paddles of an indirect paddle dryer are hollow. The hot gas heats these components, which then transfer their temperature to the moist material to achieve heat dissipation. Consequently, this permits the use of indirect paddle dryers for temperature-sensitive materials such as foodstuffs and pharmaceuticals.

Batch and Continuous Paddle Dryers

- Batch Paddle Dryer: A batch paddle dryer can only process a fixed quantity of wet material per operation. It is typically employed for small-batch drying projects and can provide more precise time control.

- Continuous Paddle Dryer: The continuous paddle dryer is the ideal drying equipment for large-scale drying projects. It permits continuous feeding of material into the unit during operation, enabling uninterrupted drying and discharge for non-stop processing.

Vacuum and Dual-Zone Paddle Dryers

- Vacuum Paddle Dryer: The vacuum paddle dryer operates within a complete vacuum environment. This vacuum reduces the boiling point of moisture within the wet material, enabling drying at lower temperatures. This effectively protects heat-sensitive materials from damage while achieving superior drying efficiency.

- Dual-Zone Paddle Dryer: The dual-zone paddle dryer is also frequently employed for drying heat-sensitive materials. In addition to its heating system, it incorporates an independent cooling zone to regulate temperatures throughout the drying process.

Advantages of Paddle Dryers

Exceptional Drying Performance

Firstly, the paddle dryer maximises heat transfer efficiency through both direct and indirect drying methods, yielding satisfactory drying performance for both viscous and powdered materials. Also, its drive shaft powers the paddles to rotate efficiently, ensuring uniform heating and preventing localised overheating or incomplete drying.

Friendly for Temperature Sensitive Materials

For drying sensitive materials, paddle dryers deliver outstanding performance. Unlike conventional drying methods, paddle dryers do not utilise thermal convection for drying. Instead, they employ indirect heating or achieve low-temperature drying through vacuum environments and cooling systems, thereby preventing damage to your heat-sensitive materials.

High Cost Effectiveness

Although paddle dryers entail a higher initial investment, they deliver superior drying efficiency while consuming less energy (achieving energy savings of 20% to 40%). Furthermore, paddle dryers provide stable drying performance for large-scale drying projects. Consequently, they generate greater overall benefits, despite the higher purchase cost.

Scalability

Paddle dryers are a highly flexible and scalable drying system. As drying requirements evolve, you may expand the system to enhance its overall drying capacity and capability without replacing existing equipment. This flexible scalability eliminates the need for substantial initial investment, energy consumption, and maintenance costs.

Low Maintenance Costs

The paddle dryer features a simple structure with few moving parts during operation, resulting in enhanced durability. This extends its service life while reducing maintenance requirements and minimising downtime and damage.

Applications of Paddle Dryers

Environmental Protection

You can use the paddle dryer to treat sludge. Consequently, they deliver highly efficient drying performance, enabling their use in industrial, municipal, and agricultural applications to treat industrial waste, municipal sludge, animal manure, and similar materials.

Chemical and Pharmaceutical Industries

Certain chemical products (such as polymers and catalysts) are also highly suitable for processing using your paddle dryer. They permit precise temperature control and ensure stable, round-the-clock operation for consistent drying. Certain pharmaceuticals are highly temperature-sensitive; employing paddle dryers enables low-temperature drying, preventing damage to your drugs and associated cost losses.

Food Processing

You can also use paddle dryers in food drying applications. Their enclosed design and cleaning protocols guarantee food hygiene and safety. Opting for a vacuum paddle dryer further isolates the process from external air, enabling low-temperature drying to prevent spoilage caused by excessive heat.

Jiangsu Fanqun Drying Equipment Factory possesses over 25 years of production expertise within the drying industry, with products exported to the United States, Japan, and numerous other countries worldwide. Should you be seeking high-quality drying solutions, our paddle dryers are well-suited to meet your requirements.

Paddle dryers commonly employ hot air, steam, or thermal oil. Owing to its superior temperature control capabilities and efficient heat transfer, steam is the most frequently utilised heating medium. Thermal oil offers excellent heat transfer performance but requires more maintenance, whereas hot air presents a lower-cost option.

Paddle dryers can process viscous sludge or sticky products containing particles. They are also suitable for drying materials sensitive to high temperatures.

Regular cleaning is required, encompassing both the dryer surface and paddles. Periodic inspection of hollow components and seals for leaks is also essential to ensure airtight integrity. Additionally, you must regularly check the supply pressure to ensure the paddle dryer operates at optimum performance.

Firstly, the paddle dryer is sealed, effectively shielding against contamination from the external environment. Secondly, for applications with high standards of hygiene, a vacuum paddle dryer can be selected to further block external polluted air for you.