FANQUN Industrial Flash Dryer

FANQUN industrial flash dryer uses multiple feeding and drying equipment with high-temperature air flow to dry your materials within seconds.

- FANQUN flash dryer has over 20 technology patents to achieve high efficiency drying.

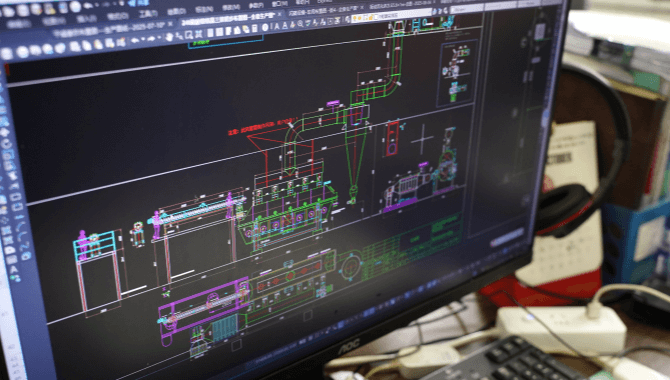

- We offer 3D modelling services to customize design industrial flash dryer of different sizes and functions.

- We provide various grades of stainless steel, duplex steels and other exotic alloys to meet your special needs.

- Our welders are certified to ASME & AWS standards with the highest standard of welding capability.

- Our industrial flash dryer both have Finite Element Analysis(FEA) certification with stable operation and long service life.

The Right Drying Solution for Your Material

Whether you are in the food industry, or other industry like chemical, pharma, energy etc, our flash dryer can always provide the right drying solution for your material.For example: calcium carbonate, kaolin, starch, pharmaceuticals, sludge, etc.

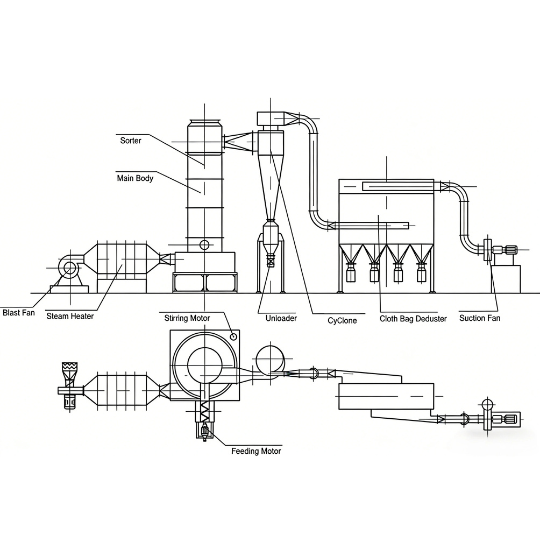

3D Structure & Airflow of Our Industrial Flash Dryer

This 3D view shows the internal structure and airflow behavior inside the flash dryer helping you better understand the drying process and material movement.

What is the Flash Dryer?

The flash dryer is a type of drying machine that uses high-temperature air flow to dry materials with high moisture content. This is one of the most efficient methods that can help you dry the feed within seconds.

How the Flash Dryer Works?

Step 1: Feeding

The first step is to feed the wet material into the feeding system of the flash dryer. Different types of materials have their own properties. You can choose a screw conveyor, a screw feeder or a rotary valve to send your material into the flash dryer.

Step 2: Intake

Then let the hot air into the drying chamber from the tangential air intake at the bottom of the flash dryer. The wet material will get into the high-speed hot air flow and the intense mixing, grinding, and stirring zone.

Step 3: Evaporation

After the material touches the hot air, the high-humidity material in the button of the flash dryer will be crushed by the blender. At the same time, the low-humidity materials on the surface will be driven up. The temperature and speed of the hot air are controlled accurately. This will form an intense heat transfer. And the material moisture will evaporate rapidly.

The turbulence helps to ensure the drying is even and prevents clumping. If you want to dry the slurry or paste form materials, then you can equip an atomizer or nozzle to atomize the material into tiny droplets; it’s a useful method to improve the drying efficiency.

Step 4: Micronization

Under the high-temperature environment, your wet material will be shearing, blowing, and mixing. Then the material will be micronized under the influence of the centrifugal force. During this period, the gas phase and the solid phase will undergo the rotational flow. Because the solid phase has greater inertia than the gas phase. The relative speed between the two phases is relatively large. This will help to enhance the mass transfer and heat transfer, and then achieve a high production strength.

Step 5: Separation and Collection

After the wet materials are totally dry, the dry particles and hot air will be separated by the process receiver or baghouse dust collector. The separated dry particles will be delivered to the storage tank and discharged through the rotary airlock.

Step 6: Exhaust Gas

The final step is to treat the exhaust gas. There is a large amount of water and particles in the exhaust gas. It is necessary to remove particulate matter before emission. On the one hand, removing particulate matter from exhaust gas is necessary according to environmental regulations. On the other hand, it is also possible to recover some useful particulate matter mixed in with the gas flow.

Flash Dryers We Make for Global Client

Spin flash dryer has various feeding devices, special cooling devices, and air distribution devices, which improve drying efficiency.

A 380V automatic food processing flash dryer made with stainless steel material and has a 9.55kW power.

An easy to operate carbon steel material flash drying equipment for food and chemical processing with customizable voltage.

A gas heating method automatic flash drying machine for cassava flour with high quality stainless steel and carbon steel materials.

A high efficiency drying 2.7kW power and 220V starch flash drying equipment with gas heating method for vegetable starch.

A stem and natural gas heating method coffee flash drying machine that is automatic and easy to operate.

A high quality stainless steel industrial continuous flash drying machine with an electricity heating method and has a customizable voltage.

A custom power and voltage stainless steel material industrial flash drying machine with a high safety level feature and can be customized with size and dimensions.

Test Your Material Before Order

We can provide you free material testing before order, we will confirm the drying performance, final moisture stability, energy consumption under real working conditions, and give you a final report, so you can check if it is the right drying equipment for you.

How FanQun Support Your Flash Dryer Order

- Design support: We will provide customized engineering designs based on your material properties and production capacity requirements to ensure optimal drying performance.

- Installation & commissioning:We offer detailed installation guidance and commissioning support to ensure the flash dryer operates safely and efficiently.

- Online support:Engineers will provide online support services such as operational guidance and troubleshooting throughout the entire lifecycle of the equipment.

- Spare parts supply:We ensure long-term spare parts supply to minimize downtime and support continuous production.

Warranty:We provide 1 year warranty service to ensure stable equipment operation.

Applications of the Industrial Flash Dryer

The flash dryer plays an important role in the renewable energy industry. It can effectively reduce the moisture content of the wood or agricultural residues, such as pulp sludge, lignin, and algae. On the one hand, it can improve your energy production efficiency and reduce the production cost. On the other hand, it can achieve the Sustainable Development Goals.

The flash dryer can quickly remove the moisture content of the ore. Furthermore, the flash dryer has a very high thermal efficiency, with an energy utilization rate of over 70%.

Whether it’s metallic ore, non-metallic ore, or tailings, flash dryers can dry wet slurry to a moisture content of less than 1-2%. Common minerals that require drying include copper concentrate and kaolin.

Flash dryers can be integrated with processes such as mineral processing, roasting, and grinding to improve the overall efficiency of mining operations.

Flash dryers are core equipment for the automated drying of chemical powders. Flash dryers are widely used in the chemical industry for various products, including inorganic and organic substances such as carbonates, calcium titanate, sodium sulfate, and silicon dioxide.

The food and feed industry also has a wide need for drying. The flash dryer can maintain product quality, nutrition, and taste while dehydrating. Whether it’s food, condiments, animal protein, plant-based products, or sugars, flash dryers can extend shelf life and prevent spoilage. Flash dryers are a crucial step in ensuring food meets safety standards.

- Technical Parameters

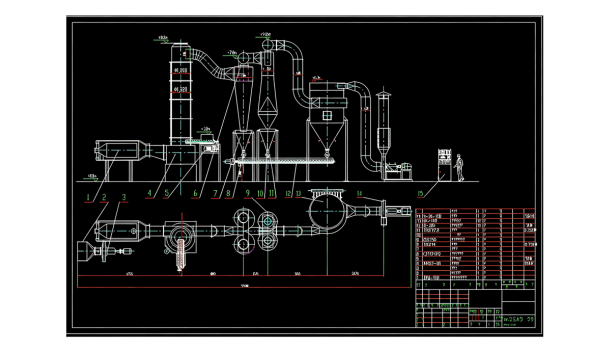

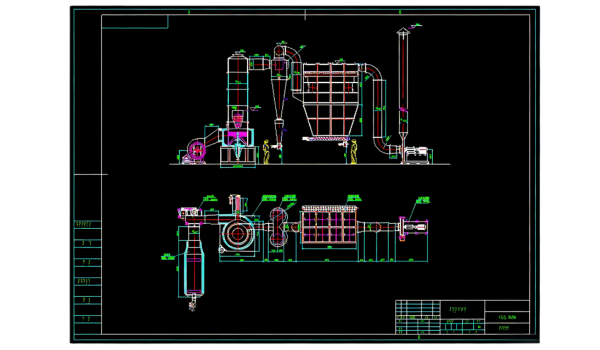

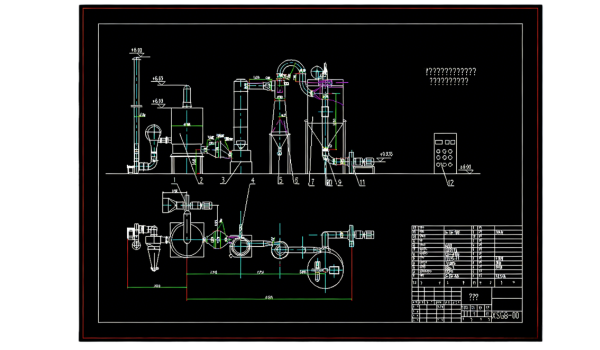

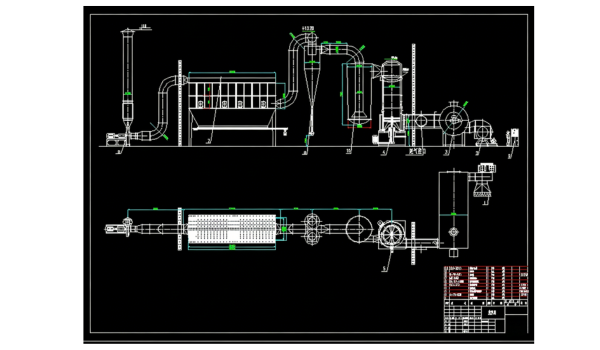

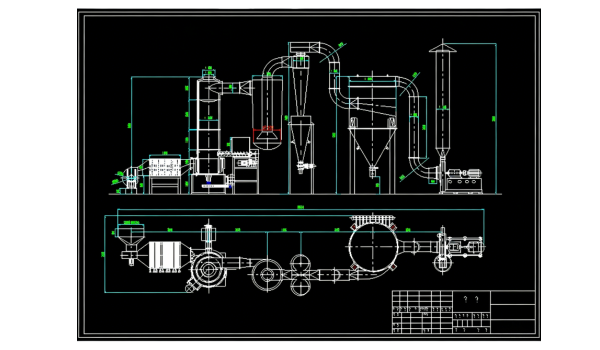

- Engineering Drawings

- Our Factory

| Model | ID of Main Machine (mm) | Air Amount (m³/h) | Evaporated Moisture (kg) | Max. Equipped Capacity (kW) | Max. Height (m) | Occupied Area (m²) |

|---|---|---|---|---|---|---|

| XSG-2 | 200 | 350–500 | 12–17 | 6–10 | 4.0 | 15 |

| XSG-4 | 400 | 1150–2000 | 40–70 | 12–20 | 4.8 | 20 |

| XSG-6 | 600 | 2450–4500 | 80–150 | 24–40 | 5.8 | 28 |

| XSG-8 | 800 | 4450–7550 | 150–250 | 38–65 | 6.4 | 35 |

| XSG-10 | 1000 | 7000–12500 | 230–420 | 55–90 | 7.1 | 40 |

| XSG-12 | 1200 | 10000–18000 | 300–600 | 80–135 | 7.8 | 52 |

| XSG-16 | 1600 | 18000–30500 | 600–1000 | 160–270 | 8.5 | 80 |

| XSG-20 | 2000 | 50000–78000 | 1000–1500 | 250–430 | 10.1 | 150 |

Notes:1.The evaporated moisture capacity is calculated with inlet air temperature of 180°C and outlet air temperature of 80°C.2. Equipped capacity is for reference and may vary depending on material properties.3. Occupied area may differ according to site conditions and layout.

Customer Feedback from Real Projects

We usually need: Material name and characteristics,initial and target moisture content,required drying capacity,heat sensitivity,site conditions,etc.The more detailed the information,the more accurate the solution.

Yes. We offer free material testing before order.Our factory is equipped with experimental machines specifically designed to do drying tests on various materials and provide a testing report for your reference.

It typically takes 5-8 weeks, depending on the level of customization of the equipment you order.

Each industry flash dryer is designed to control the final moisture content by adjusting airflow design, temperature control, and other measures according to the material characteristics.

Generally, heating methods include steam, natural gas, diesel, and electricity. We will provide a specific solution based on your site conditions and operating costs.

We provide a one-year warranty for the flash dryer,technical support and spare parts supply are available beyond the warranty period.

Advantages of the Flash Dryer

High-efficiency Drying

The flash dryer has a high-efficiency drying ability because of the combination of the hot air and the mixer. It can quickly evaporate the water in your wet material. Then shorten the residence time of the powder in the drying chamber. One drying cycle is within seconds. In addition, there is a cooling device at the bottom of the hot wind entrance, which can help prevent your heat-sensitive products from deterioration in the high-temperature zone at the bottom.

Controllable

The flash dryer is totally controllable. The drying chamber has the graded rings and swirl vanes, which can help to control the air volume, temperature and humidity during the drying period. Different drying parameters can adjust the fineness and moisture content of your materials. The moisture in the calcium carbonate can be adjusted to less than 0.1%.

Multifunctional

Whatever the powder, particles, slurry, or paste, the flash dryer has high versatility to dry different forms of materials from different industries. If your drying business needs to dry various materials in one production cycle, then the flash dryer is your best choice.

Automation

The flash dryer can be equipped with the PLC control system and online moisture content testing mold to achieve automatic temperature control, feeding and discharge. Fully automatic flash dryers can minimize manual operation. If you want to dry minerals, automatic operation devices can greatly improve the efficiency of mineral processing.

Safe

The flash dryer has a safety system to ensure total safety during the drying process. The flash dryer has standardized fire safety technology, an explosion-proof pressure relief valve, and an automatic carbon dioxide monitor to strictly ensure the operator’s personal safety. You can also equip an enhanced system in the flash dryer to prevent the dust explosion.

If you need to dry the hazardous feed materials that will produce non-aqueous solvent residues, it’s better to install an extra closed-loop hydrocyclone system. This will dry the material in the inert gases and improve the purity of your materials, such as chemical intermediates, pharmaceutical raw materials.

Types of Flash Dryers

Flash dryers can be divided into three types according to different hot air flow methods: the heated rotary flash dryer and the fluid bed flash dryer.

Rotary Flash Dryer

The heated rotary flash dryer is the most commonly used type of flash dryer now. It is a combined internal helical blade with an inclined rotating cylinder. The heated rotary flash dryer can directly contact the wet material with the drying medium, and then form two flowing methods: parallel and countercurrent. It is widely used to dry the material with low density, such as straw and leaves, or fine powders, granular materials, and pellets.

Fluid Bed Flash Dryer

The fluid bed flash dryer is a similar operation process to the heated rotary flash dryer. It can deliver the wet power, particles or flaky material to a multi-hole bed equipment. Then adjust the hot air flow speed to keep the material layer in a fluidized state. This method forces hot air through the material and dries it. So it has a strong advantage in drying the material with high-density, like wood chips or sawdust.

In the past 40 years, FANQUN has been deeply rooted in the drying equipment industry and has successfully applied for more than 20 technology patents. As a one-stop customized drying equipment solutions supplier, FANQUN offers a variety of process equipment function options for you to choose from, including drying, sterilization, calcination, shot blasting, pulverization, etc. If you need custom drying services, choose FANQUN as your manufacturer!

The flash dryer can be custom-designed for different sizes of processing power according to your needs. The largest flash dryers can process hundreds of tons of feed per hour. Also, flash dryers have evaporation capacities ranging from a few kilograms per hour to over 40 tons per hour.

No. For heat-resistant chemical products, flash dryers offer energy efficiencies of up to 70–85%. This is because the material spends a short time inside the drying chamber, reducing energy loss. If you want even higher efficiency, you can configure heat pump technology and waste heat recovery systems. This not only improves energy efficiency but also increases recycling rates.

Flash dryers are made of over 90% stainless steel, making them easy to clean. You can also achieve automatic cleaning by installing an automatic in-situ cleaning system. The automatic cleaning systems can shorten cleaning time while reducing the use of water and chemicals. This not only reduces wastewater discharge, but also saves your costs on wastewater treatment.