Features of the Single Belt Dryer

The FANQUN single belt dryer is specially designed for fragile materials, helping you achieve the gentlest and most even drying of wet materials.

- Maximum dry up to 30 tons of wet material per hour

- Mild drying keeps the nutrient retention rate at 90%

- Fully automatic control gives you a stable production quality

- A 60% thermal utilisation rate to save your energy cost

- Indirect heating or direct heating are both options.

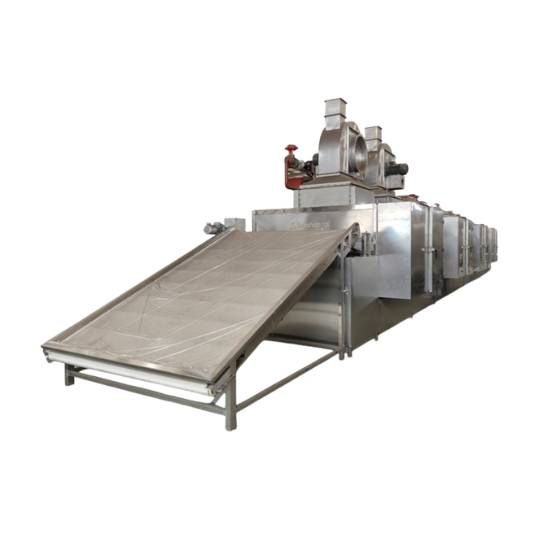

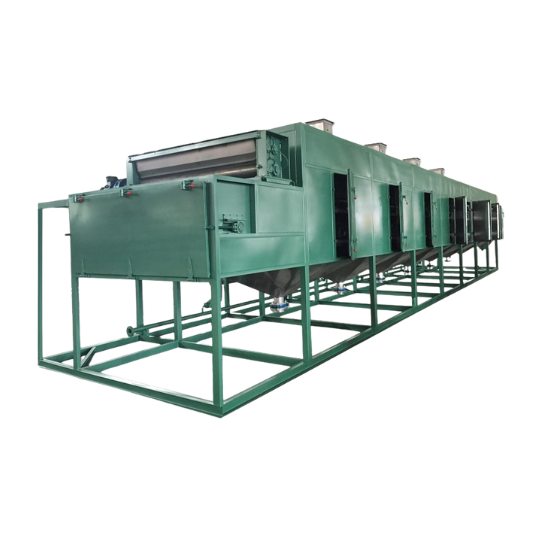

DW Series Single Belt Dryer

It is chamber constructed drying machine. In drying chamber, we equipped with multiple conveying belt. Those conveying belts moves in drying chamber. Wet material will uniformly separate on first layer of mesh belt. After the action of chains, wet material transferred from first layer to second layer. After conveying and heat exchanging in different layers, wet material is dried and finally drop on the last layer.

Air flow is counter current: High temperature and low moist air is blowing from bottom layer to upper layer and contact with wet material. When hot air contact with material, it will absorb moist inside and remove the moisture out of drying chamber by exhaust fan.

It is full automatic and continuous operating drying machine, in which raw material will turn over during falling down to next conveying belt that will ensure of uniformly drying result.

Low labor consumption and good working condition. This type of mesh belt dryer is also easy for maintenance. Bottom of the machine is designed of the swash plate and fast blanking cleaning door open, easy to clean inside the powder.

Small single belt dryer with UV curing for plastic processing, Drying and shrinking oven for plastic package.

Fast and responsive controllability, adjustable heat and belt speed. Explosion-proof and prevents erosion.

Electric power source and has a large application for dairy products. Temperature and Speed is adjustable to the preferable result.

Coated surface with mesh belt dryer in single row for Steam heating method, Food industrial application for thorough dehydrating process.

Automatic belt dryer with conveyor that ensures air drying temperature reaches thorough results. Has multiple features with adjustable volume.

Great vacuum control for packaging and plastic shrinking application, Versatile Industrial belt dryer with heat adjustment.

Coated with paint and durable exterior against any heavy impact and dent resistant. Customizable heat and pace.

Continuous belt with adjustable heat volume for various applications. The heat tunnel improved with high efficiency and excellent bactericidal effect.

- Our Factory

- Technical Parameters

| Model | DW₃ -1.2-8 | DW₃ -1.2-10 | DW₃ -1.6-8 | DW₃ -1.6-10 | DW₃ -2-8 | DW₃ -2-10 |

| Unit number | 4 x 3 | 5 x 3 | 4 x 3 | 5 x 3 | 4 x 3 | 5 x 3 |

| Belt width (m) | 12 | 14 | 16 | 20 | 20 | 20 |

| Drying section length (m) | 8 x 3 | 10 x 3 | 8 x 3 | 10 x 3 | 8 x 3 | 10 x 3 |

| Thickness of the material to be covered (mm) | 10~80 | 50~150 | 50~150 | 50~150 | 50~150 | 50~150 |

| Temperature (°C) | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 |

| Steam pressure (Mpa) | 360~600 | 420~720 | 450~840 | 480~960 | 1510~1080 | 630~1350 |

| Steam consumption (kg/h) | 810 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Heat exchange area (m²) | 150~450 | 240~650 | 220~600 | 280~750 | 300~600 | 350~850 |

| Drying strength (kg H₂O/h·m²) | 14 | 17 | 14 | 17 | 14 | 17 |

| The number of fans | 14 | 17 | 14 | 17 | 14 | 17 |

| Total power of the blower (kw) | 30.8 | 32.6 | 30.8 | 32.6 | 54.2 | 56 |

| Total power of the equipment (kw) | 35.3 | 37.1 | 35.3 | 37.1 | 58.7 | 60.5 |

| Overall dimensions (L × W × H) | 9.77 x 2.2 x 4.7 | 11.7 x 2.2 x 4.7 | 9.77 x 2.6 x 4.7 | 11.7 x 2.6 x 4.7 | 9.77 x 3.06 x 4.7 | 11.77 x 3.06 x 4.9 |

| Weight (kg) | 4900 x 3 | 5780 x 3 | 5400 x 3 | 6550 x 3 | 6350 x 3 | 7800 x 3 |

What is the Single Belt Dryer?

The single belt dryer is also called a continuous convection drying system. It uses a conveyor belt to deliver the wet material to the drying chamber, and then the equipment will mildly and evenly dry your materials into the final products. The single belt dryer is mainly used to dry products that are easily fragile.

How does the Single Belt Dryer Work?

The core working principle of the single belt dryer is to let the wet materials do the convective heat transfer and mass transfer in the hot air, finally achieving continuous dehydration. The specific working steps can be divided into 4 steps.

Step 1: Feeding

The first step is to feed your materials to the single belt dryer. The wet material will be spread on the belt by the feeding device. The feeder employs variable frequency control to deliver wet material onto the belt at a steady flow rate.

Then the oscillating distributor will repeatedly oscillate to sweep the material across the entire belt, achieving a uniform distribution in the lateral direction. After that, the leveling device will ensure that the materials are of the same thickness; it is an important device to make sure materials have even moisture.

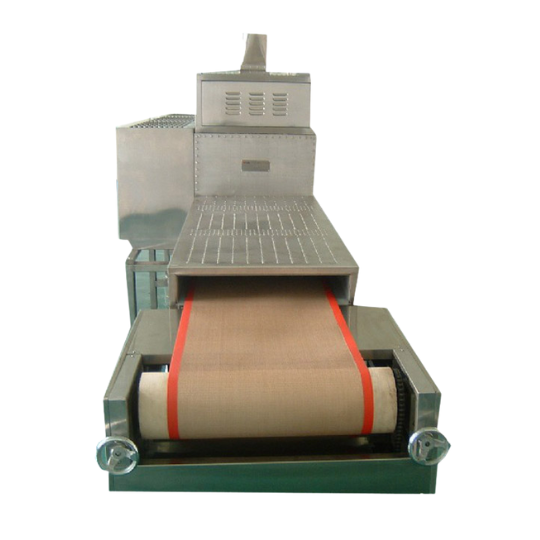

Step 2: Delivery and Heating

With the running of the belt, your wet materials will be continuously delivered into the chamber at a set speed. In the chamber, there is a heating system that can produce constant hot air to dry the materials. Commonly, you can choose steam heat exchange, electric heating, hot blast stoves or gas systems to do the heating work. The specific heating method depends on your needs.

Step 3: Drying and Cooling

The belt will deliver your wet material to the drying area, which has a heating plate at the bottom. Then the hot air will go through the materials layer from top to down or from bottom to up. When the hot air gets into the drying area, it will take away the moisture through full exposure to the materials. After the drying process, the dried materials will be delivered to the cooling section, where the cooling panel will cool the products while they are still on the belt.

Step 4: Discharging

Finally, the materials will be discharged at the end of the belt for further processing or packaging. The used energy, such as hot water or waste heat, can be recycled for other operations of equipment.

Advantages of the Single Belt Dryer

High-efficiency Drying

The high-efficiency drying does not mean drying fast. It uses a thin-layer material with continuous conveying to achieve continuous, uninterrupted drying. Usually, the materials layer is 10 to 80 mm controllable. Also, the convection heat transfer plus hot air penetration can maximize the effective heat exchange area.

In addition, the wind volume and wind pressure are controllable. The Single Belt Dryer does more than just blow air onto the surface of wet materials; it penetrates deep into the material for thorough drying. Compared to rotary dryers, single belt dryers ensure that every second the material stays in the container is dry. The evaporation water volume can reach up to 30 tons/hour.

Mildly Dry

Compared with other dryer machines, the single belt dryer is milder in drying materials. You can set the drying temperature to low or mid-range; this can help to reduce the rotational speed to prevent your materials from overheating. At the same time, the gentle air cycle can keep the health status of food and other items.

By the way, you can choose to equip your single belt dryer with a vacuum technology to provide extra protection. The vacuum technology can help to protect your products in good color, mouthfeel and nutritional information. The suitable belt and airflow setting are important issues to protect fragile items from damage during drying.

Highly Flexible

The single belt dryer is a modular design with high flexibility. Although it has only one belt, it can be equipped with extra belts to suit various kinds of applications and a capacity range. Heating also offers considerable flexibility. You can choose indirect or direct heating to dry the wet materials.

- Indirect Heating

The hot water, steam or thermal oil will heat the cycle air through the heat exchanger, then the hot air will use convection heating to heat the wet material.

- Direct Heating

You can burn gas or diesel to form high-temperature smoke gas. Then the smoke gas can mix with the air to get into the drying chamber directly.

Fully Automatic

The single belt dryer is a fully automatic system with PLC control. You can use the sensor to monitor the temperature, air flow, and other physical parameters continuously. You can smartly control the drying temperature, drying time, wind speed and wind direction to make your machinery suitable for wet materials with different features.

The fully automatic system can maintain consistency during the drying process. It can ensure your product quality is under the same standards and improve your production efficiency.

Energy Saving

First, the single belt dryer is very energy-efficient. The thermal utilisation rate of the single belt dryer is typically over 60%. You can equip a waste heat recovery system to improve the system’s COP(Coefficient of Performance) in the next step. Which means you can use a single belt dryer to dry more wet materials with less energy. It’s a cost-reducing method by recycling waste heat or hot water.

Applications of the Single Belt Dryer

The single belt dryers are widely used in various industries. It is suitable for the industry that has high quality in drying uniformity, temperature control and continuous production.

Food

The single belt dryer plays an important role in the food industry. Whether it’s fruits, vegetables, or grains, the single belt dryer can achieve fast and even drying through a perforated conveyor belt and hot air. It can keep the color, taste and nutritional content of food. In addition, drying can also prevent food from spoiling and extend its shelf life.

According to the experimental results, the processing capacity of food drying can reach a maximum of 2 tons each hour. The color retention rate of the food color is about 95%. Most importantly, the nutrient retention rate can reach 90%.

Biomass

The single belt dryer can also be used to dry biomass. Such as wood shaving pellets, crop pellets and organic waste. The biomass has a high moisture about 30-65% with irregular shapes. Furthermore, the drying process of biomass generates a large amount of powder, which can easily lead to explosions. Therefore, the selection of equipment is crucial when drying biomass.

Biomass, such as waste, dried using a single-belt dryer, can become a cleaner energy source. Furthermore, when used to dry materials like sludge or wood waste, the moisture content can be reduced from 40–60% to 8–12%.

Chemical Pharmaceuticals

In the chemical pharmaceutical industry, the single belt dryer is often used to dry the extracts, active pharmaceutical ingredients. The biggest advantage of the single belt dryer is that it can control the drug water content within ±0.2%. The single belt dryer usually operates in a closed system to prevent the powder from running out.

This can protect your staff’s personal safety. The single belt dryer is mainly made from stainless steel, compliant with GMP requirements, which removes the risk of cross-contamination. The single belt dryer meets strict production standards and dries the active ingredient and other components without damage.

As a professional dryer manufacturer, FANQUN focuses on offering a one-stop dryer solution all over the world. In the past 10 years, FANQUN has successfully installed 350 drying production lines worldwide.

The belt will wear down during continuous transmission, so it is necessary to check the situation frequently. After daily working of the single belt dryer, you need to adjust the belt tension and clean the system to prevent the grime. You can choose a cleaning manual or equip the CIP system to do the automatic cleaning.

- Single Belt Dryer: The structure of the single belt dryer is simpler. Therefore, the amount of material that can be processed is relatively small, ≤ 3–8 tons/hour. The single belt dryer has the flexibility that can be replaced with new materials at any time.

- Multi-Belt Dryer: The multi-belt dryer usually has 2 to 6 belts with complex structures, which means it can support continuous large-scale production. It can dry over 10 tons per hour. If you need to dry a single material for a long time, then a multi-belt dryer is suitable for you.

The most economical heating method always depends on your specific drying situation. If you have residual heat, then the waste heat recovery system is the best choice. If you can use steam, then the steam heat exchange is a stable choice. The cheapest choice is natural gas, which has a high cost-performance on direct combustion. If you only need to dry small-scale wet materials, then electric heating is a good choice.