Features of FANQUN Multi Belt Dryer

The multi belt dryer can deliver even and gentle hot air to quickly dry materials, providing high-quality products in large quantities.

- Multi-layer belt makes drying even with high efficiency

- Made of stainless steel or carbon steel, solid and durable

- Energy saving, lower operating costs

- Precise temperature control produces high-quality products

- Enclosed structure prevents dust and cross-contamination

- FANQUN multi belt dryer undergoes strict inspection and obtains ISO9001 certification

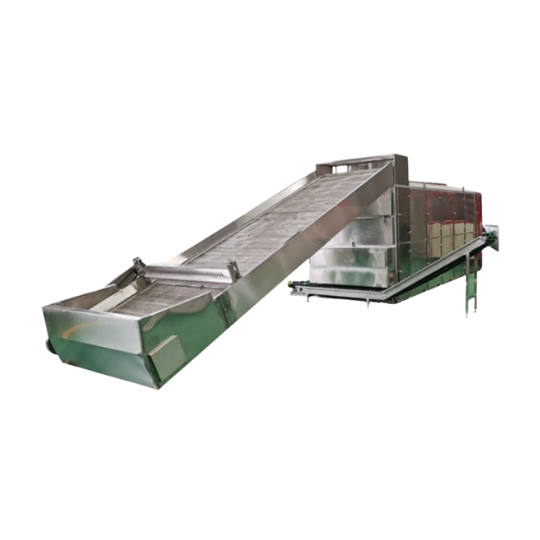

DFQ-DW-DC Multi Belt Dryer

It is chamber constructed drying machine. In drying chamber, we equipped with multiple conveying belt. Those conveying belts moves in drying chamber. Wet material will uniformly separate on first layer of mesh belt. After the action of chains, wet material transferred from first layer to second layer. After conveying and heat exchanging in different layers, wet material is dried and finally drop on the last layer.

Air flow is counter current: High temperature and low moist air is blowing from bottom layer to upper layer and contact with wet material. When hot air contact with material, it will absorb moist inside and remove the moisture out of drying chamber by exhaust fan.

It is full automatic and continuous operating drying machine, in which raw material will turn over during falling down to next conveying belt that will ensure of uniformly drying result.

Low labor consumption and good working condition. This type of mesh belt dryer is also easy for maintenance. Bottom of the machine is designed of the swash plate and fast blanking cleaning door open, easy to clean inside the powder.

Drying cabinet with auto-moving belt and constant temperature, has adjustable speed and heat volume, Low noise and great food processing.

Commonly used for drying sweet treats and Personalized customization for more efficient use.

A continuous multi-layer belt with hot air drying for organic materials, Has accurate temperature rate and explosion-proof steel.

Smooth flow mesh belt manufactured with stainless steel, Electric heating method. Air cooling and equipable enclosure.

Strong carbon steel material and high productivity, electric engine with energy saving move. Speed control is adjustable.

Automatic belt dryer with continuous moving belt through oven tunnel, Steam is used to heat up the products more efficiently.

Automatic belt dryer with continuous moving belt through oven tunnel, Steam is used to heat up the products more efficiently.

The machine is equipped with a conveyor store. Has excellent steam heating function with over 5 layers installed and easy to operate.

- Our Factory

- Technical Parameters

| Model | DW₃ -1.2-8 | DW₃ -1.2-10 | DW₃ -1.6-8 | DW₃ -1.6-10 | DW₃ -2-8 | DW₃ -2-10 |

| Unit number | 4 x 3 | 5 x 3 | 4 x 3 | 5 x 3 | 4 x 3 | 5 x 3 |

| Belt width (m) | 12 | 14 | 16 | 20 | 20 | 20 |

| Drying section length (m) | 8 x 3 | 10 x 3 | 8 x 3 | 10 x 3 | 8 x 3 | 10 x 3 |

| Thickness of the material to be covered (mm) | 10~80 | 50~150 | 50~150 | 50~150 | 50~150 | 50~150 |

| Temperature (°C) | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 | 0.2~0.8 |

| Steam pressure (Mpa) | 360~600 | 420~720 | 450~840 | 480~960 | 1510~1080 | 630~1350 |

| Steam consumption (kg/h) | 810 | 1020 | 1056 | 1320 | 1344 | 1680 |

| Heat exchange area (m²) | 150~450 | 240~650 | 220~600 | 280~750 | 300~600 | 350~850 |

| Drying strength (kg H₂O/h·m²) | 14 | 17 | 14 | 17 | 14 | 17 |

| The number of fans | 14 | 17 | 14 | 17 | 14 | 17 |

| Total power of the blower (kw) | 30.8 | 32.6 | 30.8 | 32.6 | 54.2 | 56 |

| Total power of the equipment (kw) | 35.3 | 37.1 | 35.3 | 37.1 | 58.7 | 60.5 |

| Overall dimensions (L × W × H) | 9.77 x 2.2 x 4.7 | 11.7 x 2.2 x 4.7 | 9.77 x 2.6 x 4.7 | 11.7 x 2.6 x 4.7 | 9.77 x 3.06 x 4.7 | 11.77 x 3.06 x 4.9 |

| Weight (kg) | 4900 x 3 | 5780 x 3 | 5400 x 3 | 6550 x 3 | 6350 x 3 | 7800 x 3 |

What is a Multi Belt Dryer

A multi-belt dryer is a continuous drying equipment and can process large quantities of materials. Through multi-layer conveyor belts, materials are dried evenly and quickly. It is simple to operate and takes up little space. You can apply it in the food, chemical, and agricultural industries.

How does a Multi Belt Dryer Work

First, the feeder evenly spreads the material on the upper conveyor belt. Subsequently, hot air passes horizontally or vertically through the layer inside the drying box. The multiple conveyor belts move downwards sequentially, gradually dehydrating material in different temperature zones. The entire process is gentle and easy to control.

A circulating fan repeatedly pushes the hot air, improving thermal efficiency. After that, the exhaust fan takes out the humid air. Finally, the material is discharged from the bottom outlet. You will obtain a high-quality, well-dried product.

Main Components of Multi Belt Dryer

- Feeder

The feeder is responsible for evenly feeding material into the dryer to improve the consistency of drying. Some common feeding methods include vibratory feeding, screw feeding, or belt feeding. When you are processing materials that are prone to sticking together, you can add a pre-dispersion device to enhance drying efficiency.

- Drying Box

The drying box features a sealed structure to diminish heat loss. The body is usually made of stainless steel or carbon steel, offering corrosion resistance and high strength. It can withstand continuous production for a long time. A reasonable internal air circulation makes even hot air flow between layers, improving the product drying effect.

- Heating Source

The multi-belt dryer supports various heating methods, including electric heating, oil, natural gas, coal, wood chips, and steam.

Electricity is cleaner and can help you precisely control the temperature. Oil is suitable for large-scale continuous production. Natural gas and steam are affordable and heat up quickly. But for agricultural product processing, wood is more suitable.

- Multi-layer Conveyor Belts

The material of conveyor belts is usually stainless steel or high-temperature resistant plastics, featuring corrosion resistance, high load-bearing capacity, and good air permeability. The multi-layer design increases space utilization rate, increases your productivity per unit area, and enables every piece of material to be fully exposed to hot air.

- Fan

Fans are key devices for hot air circulation and dehumidification. Circulating fans blow hot air onto the material surface, increasing convective heat transfer efficiency. It also makes for faster drying and lower energy use. Dehumidification fans are responsible for removing humid air to prevent moisture accumulation from affecting the drying effect.

- Discharge Port

The discharge port allows the dried material to flow out smoothly. For granular, powdery, or fragile products, a cushioning structure can be used to reduce damage caused by material drop.

- Control Pannel

The control panel allows for intelligent control of parameters such as temperature, speed, airflow, and humidity. You can also set drying formulas for different materials and retrieve them with a single click, reducing operation errors and significantly improving your production space.

Benefits of Multilayer Belt Dryer

Robust Modular Design

The multi-layer belt dryer adopts a modular design, occupies a small area, and is easy to install, making it ideal for workshops with limited space but pursuing high output. You don’t need to worry about difficulties in expanding production later. Just add modules as required, saving time and costs. Moreover, the entire machine, conveyor belt, and casing are made of stainless steel, delivering long-term corrosion and contamination-free operation, thus it is ideal for the food industry.

Produce High Quality Product

Our drying machine, equipped with a sealed drying box, can help you effectively isolate dust and contaminants to ensure the purity of your dried products. Hot air flows upwards through the conveyor belt, achieving uniform heat exchange and preventing localized over-drying or incomplete drying.

Meanwhile, it features adjustable temperature areas, letting you perform segmented fine control. Combined with a variable frequency speed control system, drying time can be flexibly adjusted according to your product characteristics. For example, fruit can be dried to below 10% moisture content while keeping its color and texture. Ensure your products truly realize high consistency and high quality, attracting more repeat customers.

Saving Energy and Operating Costs

Multi-layer belt dryers combine heat recovery and air circulation systems. Compared with conventional single-layer or box-type dryers, it can save up to 30% of energy consumption. Simultaneously, their enclosed structure eliminates heat loss and improves thermal efficiency, and your energy cost will be lower for the same output.

Furthermore, the entire line can be monitored by one operator, and with automatic feeding and unloading systems, your drying process is more stable and smooth. At this point, you can achieve higher output with lower employment and operating costs. So, what reason is there not to choose a multi belt dryer?

Large Output in a Short Time

When you pour materials into the dryer, they pass through multiple belts, and the moisture will evaporate quickly and thoroughly. Compared to conventional single-layer equipment, production capacity can be increased by 2–5 times within the same floor space, and processing time can be shortened by 35%. Meanwhile, the continuous conveyor belts can operate stably 24 hours a day, making it ideal for large-scale production.

In short, using a multi-layer belt dryer allows you to respond to customer needs quickly, accelerate delivery, and enhance your market competitiveness.

Applications of Multi Belt Dryer

Food Processing

Multi-belt dryers can gently dehydrate materials such as fruit slices, diced vegetables, herbs, and nuts. These foods are best dried at low to medium temperatures of 50–80°C, ensuring sufficient drying time while preventing problems such as blackening, stickiness, and nutrient loss. Furthermore, the airflow and temperature of each belt can be individually controlled, reducing scrap rates and improving overall production stability.

Pharmaceutical

These dyers are ideal for drying pharmaceutical granules, powders, and other similar materials. Constructed entirely of stainless steel, the surface is easy to clean and fully complies with GMP requirements.

Meanwhile, the multi-layered belts and enclosed structure also reduce cross-contamination risk and ensure consistent moisture content across batches. It will help you meet the stringent requirements of the pharmaceutical industry. Equipping with online monitoring will decrease operational errors and boost the drying effect.

Chemical

Using a multi-belt dryer can effectively prevent the thermal degradation of your materials, such as catalysts and resin particles. Multi-zone independent temperature control ensures that your product properties are not compromised, improving yield.

You also don’t need to worry about the dryer being corroded by acids or alkalis. The stainless steel material is the guarantee for your continuous and long-term processing.

Produce

Compared to high-temperature rapid drying, multi-belt dryers can prevent grains from overheating, cracking, or bursting, and allow the internal moisture to be evenly discharged, maintaining the natural color and nutrition. The equipment can also easily handle large quantities of material during harvest season. Moreover, precise moisture control enhances the safety of your product storage and diminishes the risk of mold.

We have more than 30 years of experience in the production and development of drying equipment, and we promise that each machine will be tested by our skilled technicians, ensuring optimal performance when you use it.

Don’t hesitate to contact us if you have any questions.

Although multi-layer belt dryers can save your floor space, they require a higher ceiling height in the factory. At the same time, the internal temperature and air volume control are more precise, and experienced operators are necessary.

Generally not. However, if the temperature is too high, the airflow is uneven in some areas, or the material layer is too thick, it may cause the product to discolor or become brittle. Furthermore, for extremely brittle and fragile products, deflectors or elastic receiving pads can be installed to prevent breakage caused by falling.

Single layer dryers have shorter drying paths, resulting in shorter drying times, making them more suitable for small to medium batch production. Multi-layer dryers, on the other hand, have higher heat utilization rates and can achieve continuous drying at different temperature zones, and are suited for processing large-scale materials.

You can select belts with a Teflon non-stick coating and spread the material evenly to avoid excessive moisture. Meanwhile, the belt should be cleaned regularly, and installing an automatic scraper can further decrease your cleaning time.

It may be caused by insufficient air distribution, which can also lead to a lower output and more energy expenses. You can adjust the distribution baffle to 45° to make the air flow on both sides equal.