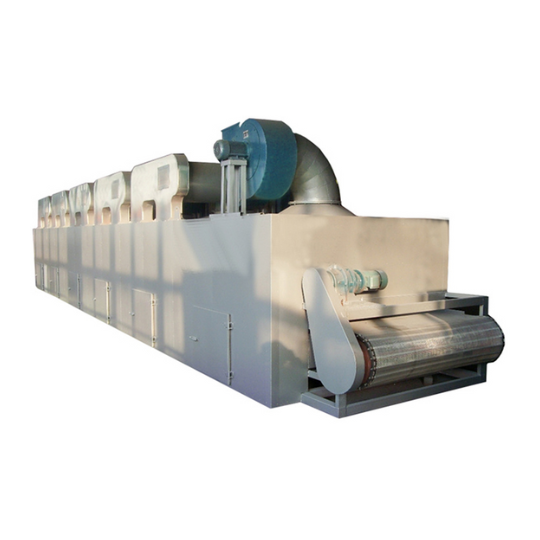

Features of FANQUN Belt Dryer

FANQUN’s belt dryer is used to handle various types of materials, offering a precise and safe drying process while also providing high production and energy efficiency.

- Feature multiple temperature zones(3- 5) to control the drying process precisely;

- Equipping with heat pump technology, reducing 30% energy consumption;

- The drying time of the belt dryer is around 10 mins to 8 hours and can be adjusted;

- Provide mild drying processes, which is especially suitable for heat-sensitive materials;

- The belt dryer offers 0.5m- 4m belt width to handle different sizes of raw materials;

- All of FANQUN’s belt dryers obtain CE and ISO 9001 certifications, while also meeting FDA and HACCP for food-grade applications.

Technical Specifications

| Model | DW Series | Temperature Zone | 3- 5 |

| Belt Material | 316L stainless steel, PTFE | Types | Single belt dryer, multi belt dryer |

| Belt Width | Around 0.5 to 4 meters | Design | Heat pump technology |

| Adjustable Parameters | Air volume, heating temperature, material residence time, and feeding speed | Energy Consumption | Can be reduced by 30%, most of the air is recycled |

| Drying Time | 10 mins to 8 hours (adjustable) | Certifications | CE, ISO 9001, FDA, HACCP |

| Heat Source | Steam, thermal oil, electricity or coal-fired (oil) hot air furnace | Applications | Food, timber industry, various pellets, cement, crops, renewable materials, etc |

It is full automatic and continuous operating drying machine, in which raw material will turn over during falling down to next conveying belt that will ensure of uniformly drying result.

Low labor consumption and good working condition. Bottom of the machine is designed of the swash plate and fast blanking cleaning door open, easy to clean inside the powder.

Low energy consumption and constant material, largely suitable for meat and organic material production. Size or dimension is customizable.

Tunnel belt air drying machine and easy to operate, Electric and gas heat source with stainless steel build. Adjustable temperature produces an energy saving feature.

Manufactured with a conveyor for material transfer into oven dehydration, the belt speed and oven temperature is adjustable for preferable results.

Has manual control panel and multifunction, wide application for food and plant dehydration, adjustable pace and temperature degree.

Fruit drying mesh process with adjustable pace and long lifespan. Energy saving and temperature control.

Ideal for organic materials and exits odor from ventilation. Creative belt dryer with automation control ensuring the preferable result of the product.

Manufactured for thorough drying faction, mesh tray belts for product transfers to rest or cooling before pushed.

Fast heat up and adjustable speed, Application is largely in rubber or metal packaging with electric heating method.

What is Belt Dryer

A belt dryer features a durable belt to build a mesh conveyor system, achieving precise partition control. Each zone has independent control capacity on temperature, air flow, and humidity. The belt dryer typically consists of mesh belts, a hot air circulation system, heating devices, control systems, and other components. FANQUN’s DW series belt dryer can be divided into single belt dryer and multi belt dryer to meet your different requirements.

How Does the Belt Dryer Work

- Step 1 – Material Conveying: Raw materials are feeded in the belt dryer and placed on the belt evenly. The thickness and uniformity of the material is directly connected to the drying speed and final product quality. Through the drive system of this machine, materials advance with a steady speed following the mesh belts.

- Step 2 – Hot Air Drying: The belt dryer is equipped with a hot air circulation system to output warm and mild air continuously. The hot air offers two different blowing directions including upward airflow and downward airflow. It can through the materials and heat the water contents to achieve the drying process.

- Step 3 – Stepwise Dehydration: The belt dryer can be divided into 3- 5 temperature zones to achieve precise control. Based on different conditions of the material, multiple temperature zones support adjusting airflow, temperature, and other parameters to handle the material. This design of the belt dryer is important to ensure an uniform drying process.

- Step 4 – Exhaust Humid Air: The humid air generated during the drying process can be exhausted through a dehumidification fan. This process just removes humidity of the materials and machine, keeping hot air circulate within the belt dryer. The dehumidification structure of the dryer improves evaporation efficiency and reduces heat loss.

- Step 5 – Energy Recovery: After the drying process, the belt dryer can recover most of the hot air and reuse it. Some machines also support installing exhaust heat recovery systems for further energy savings. Then the final product materials are cooled and packaged.

Advantages of Belt Dryer

Excellent Product Quality

The belt dryer provides continuous and warm air for raw materials, ensuring the hot air through materials evenly. This efficiently prevents localized overheating or insufficient drying to ensure high consistency of the final products. Unlike traditional drying methods, the belt dryer offers mild processes to maintain completeness of the materials, thereby enhancing product commercial value. It is also suitable for heat-sensitive materials by adjusting processing temperature, preserving the active components of raw materials.

High Efficiency

Mesh belts of the belt dryer are mainly made of 12- 60 mesh stainless steel wire mesh, offering good ventilation and temperature resistance. This type of stable structure ensures a reliable operation process, reducing downtime rate to achieve continuous production. The belt dryer supports assembly line production to handle multiple processes, such as feeding, drying, and more. This means it does not need many operators to achieve the drying process, which can decrease your labor cost and enhance the stability of the machine. The belt dryer is also suitable for large-scale projects to improve capacity per unit time.

Adaptability and Flexibility

The belt dryer offers high compatibility to handle different materials from feed pellets, sliced fruits to sludge cakes, herbal paste, and chemical filter cakes. It also supports drying various types of materials to meet different industry requirements. The core parameters of the belt dryer such as the number of layers, belt width, operating speed, airflow direction, and more, can be customized to adapt to different processes.

Low Cost

Multiple independent temperature zones of the belt dryer achieve precise control to meet different demands during different stages of the drying process. This minimizes energy consumption, but also ensures high production efficiency. The belt dryer also features a hot air circulation system to collect and reuse a large amount of heats, reducing heat loss and improving the energy efficiency. In addition, it is equipped with various functional components to achieve different processes, which can reduce your equipment purchasing costs.

Environmentally Friendly

The belt dryer features enclosed structure to prevent dust leakage while also protecting the products. By the recovery system, humid air and other exhaust gases can be removed to meet the environmental emission standards. If your project involves flammable and explosive materials, the belt dryer can be also equipped with explosion-proof structures or other designs. For the food and medical industry, the machine also meets the demands of sanitary.

Applications of Belt Dryer

Food Industry

The belt dryer features hygienic design and is made of food-grade materials to meet FDA and HACCP demands thereby being used in the food industry. It offers a mild drying process with low temperature to handle fruits, vegetables, and seafood. For active components or nutritional content, the belt dryer provides efficient protection to keep completeness. It is also suitable for pet food, ensuring excellent flavor and nutrition.

Chemical Industry

Materials used in the chemical industry typically feature complex properties such as high viscosity. The belt dryer offers stable drying processes to handle different materials, including resins, catalysts, adsorbents, pigments, chemical powders, and more. It efficiently prevents chemical property changes caused by overheating issues. And the dryer can be also equipped with inert gas to enhance the safety of the drying process.

Wood Industry

You can also use the belt dryer to handle dry wood chips, sawdust, and biomass pellets. It efficiently removes water contents of the wood and other wood products to produce fuel or composite materials. Some high-end wood materials can be dried by the belt dryer to improve their service time and added value.

Pellet Industry

The belt dryer is also widely used for the pellet industry, such as biomass, feed, or fertilizer pellets. It offers precise control and uniform drying processes to achieve high consistency of the pellets. The belt dryer also ensures active ingredients remain intact, which makes it very suitable for the medical industry. It also maintains clean operation based on the stainless steel structure to meet cleanliness requirements.

As a professional dryer supplier, FANQUN features a mature production line and advanced technology to ensure high machine quality. We have accumulated more than 30 national patents to provide reliable belt dryers for you. If you have any questions about the belt dryer, please feel free to contact us for professional solutions.

The belt dryer is suitable for various materials, such as sheet-like, strip-like, granular, and thin-layer materials. It can be also used to handle some high-viscosity materials and partially formed materials.

The biggest difference between a single belt dryer and a multi belt dryer is their capacity to handle different materials. The single belt dryer is suitable for drying thin materials within a medium-scale project. While a multi belt dryer achieves higher production capacity in the limited footprint, improving the drying efficiency.

You can select the most suitable one for the dryer based on actual requirements. When choosing the heat source, you can consider comprehensive factors, including local energy price, temperature demands, and more. In general, the food industry typically uses steam as the heat source. While for projects that are sensitive to energy cost, the natural gas or heat pumps are good choices.

Yes. The belt dryer is equipped with IoT-enabled monitoring systems to ensure it can be integrated into your smart factories. It is easy to connect the belt dryer with other smart equipment due to its high automation level.