When processing industrial or municipal sludge, you have to select the proper drying technology. Your decision will influence energy consumption, the quality of the output, safety, and cost of operation. The paddle and thin film dryers are the most popular ones in wastewater and sludge treatment sectors.

Both systems dry sludge, but they apply various mechanisms, designs, and performance levels. This guide will assist you to know each of the options so that you can choose the best solution for your plant.

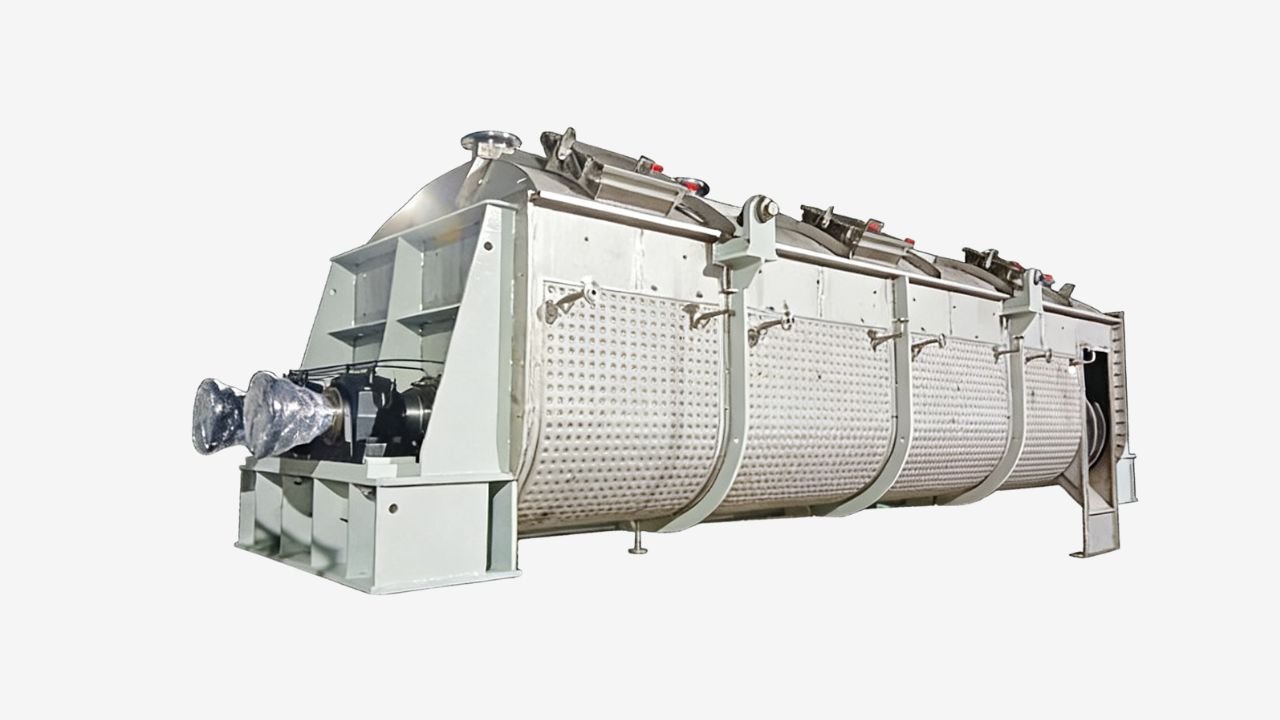

What Is a Paddle Sludge Dryer?

A paddle sludge dryer dries sludge by indirect heating. The unit employs two counter-rotating shafts with wedge-shaped paddles.

You warm the paddles and the jacket using steam, thermal oil, or hot water. The paddles stir the sludge continuously. Such mixing accelerates the process of drying by increasing contact with the heated surfaces.

Paddle dryers are ideal for sticky, pasty, and high-moisture sludge. You apply them to sludge in the municipal, chemical, and industrial by-products that require a stable and homogeneous drying process.

What Is a Thin Film Sludge Dryer?

A thin film sludge dryer has a rotating rotor with adjustable blades. The rotor spreads sludge into a fine coat on a hot wall.

Heat the wall using steam, thermal oil, or electricity. The thin film enhances the heat transfer and lowers the residence time.

Thin film dryers are effective for sludge that is of low viscosity or sludge that produces a manageable film. In petrochemical, food, pharmaceutical, and fine-chemical sludge, you frequently use them.

Differences Between Paddle Sludge Dryer and Thin Film Sludge Dryer

· Working Principle

A paddle dryer consists of two rotating shafts with hollow paddles attached to them. The paddles transport sludge in the hot trough. You rely on conduction heat. The paddles also stir the sludge at all times to enhance contact with hot surfaces.

A thin film dryer has just one rotor with mounted blades. These blades disperse sludge in a fine layer on a hot wall. You rely on fast surface renewal. The thin film guarantees quick evaporation and processing within a short period.

· Level of Automation

A paddle dryer may have a high level of automation. You also have sensors to control feeding, heating, mixing, and discharging.

Automation is also used in a thin film dryer. It, however, requires stricter control. You should ensure that you have the right film thickness and rotor speed.

· Sludge Dryer Design

A paddle dryer is one with a horizontal trough having two rotating shafts. The trough is heated by being jacketed. The design promotes heavy loads and high mixing.

You get even drying since the sludge flows steadily through the paddles.

A thin film dryer employs a vertical or horizontal cylindrical body. Its rotor has adjustable blades. These blades wipe sludge over the surface.

The body is small and occupies a small floor space. You acquire a simple flow path with minimal back-mixing.

· Mechanism of Heat Transfer

The paddle dryer operates on conduction. The heat passes through hollow paddles and the hot jacket. You obtain controlled, sluggish, and uniform drying.

The thin film dryer utilizes conduction as well as fast surface renewal. The thin sludge layer enhances evaporation. You get higher drying rates with a lessened amount of contact time.

· Operating Temperature

A paddle dryer operates at low and medium temperatures. Your typical operating temperature is 100 -250°C. This helps in preserving delicate sludge and lessens the formation of odor.

Higher temperatures can be used in a thin film dryer. You run to 300°C depending on sludge. The thin film eliminates overheating by distributing material evenly.

· Energy Efficiency

A paddle dryer is highly energy-saving. Its conduction heat system minimizes the loss of energy. You reutilize the heat in the jacket and paddles.

The slow movement reduces the consumption of power.

A thin film dryer is also efficient, but does not act in the same way. The heat transfer resistance is minimized by the thin layer. You can obtain quick evaporation with average power consumption.

Nevertheless, sticky sludge may elevate rotor power.

· Product Characteristics

The paddle dryer has granular, uniform output. You achieve uniform size of particles because of uniform mixing. The product can be used in incineration, composting, and fuel uses.

In a thin film dryer, fine powder or flakes are produced. You get dry solids of minimal moisture content. The output is good in chemical feed, fuel preparation, and stable storage.

· Residence Time

A paddle dryer aids in the long residence time. You carry sludge for long durations. This assists you in drying hard, sticky, or high-moisture sludge.

A thin film dryer has extremely short residence time. Sludge remains in the chamber for several minutes. You achieve high drying rate, but have poor capability of treating very wet feeds.

· Final Dry Solid Content

A paddle sludge dryer permits a long residence time, such that you can dependably obtain 90 percent or higher dry solids in sludge. Constant mixing provides even and deep drying.

Thin film sludge dryers are focused on rapid evaporation of surfaces. Most sludge cases contain 50%-80% dry solids, though higher levels are uncommon.

· Capacity

A paddle dryer works with high volumes. You deal with heavy sludge with constant throughput. Its design is appropriate for industrial and municipal plants.

A thin film dryer deals with average capacity. It suits chemical sludge and specialty applications. You apply it when it is more important to have precision than capacity.

· Noise Level

A paddle dryer is a low-noise appliance. The system rotates slowly. You get a low vibration and less mechanical noise.

A thin film dryer rotates a bit faster. Rotor speed generates a little noise. Quiet surroundings might require you to have noise control.

· Maintenance Requirements

A paddle sludge dryer requires less frequent maintenance. But when internal components require a replacement, the cost is high, and the time spent is longer.

A thin film sludge dryer requires more frequent maintenance. Nevertheless, replacement of the blade is easy, cheap, and normally done by the plant personnel.

· Risk of Explosion

A paddle dryer has a low risk of explosion. You utilize indirect heating with no direct flame. The closed system is used to manage dust and vapor.

A thin film dryer is also not risky. However, hot weather could raise vapor load. You have to make sure that there is adequate ventilation and supervision.

· Sludge Type and Its Suitability

A paddle dryer can work with various types of sludge. You work with municipal, chemical, industrial, oily, and sticky sludge. Wide applications are supported by the strong mixing action.

A thin-film dryer is appropriate for free-flowing or moderately adhesive sludge. You apply it to chemical sludge, solvent sludge, and organic material. It does not suit heavy mineral sludge.

· Continuous Operation

A paddle dryer facilitates constant flow. You work long hours and with few interruptions. The system manages the change of sludge consistency.

A thin film dryer also operates continuously. It must, however, have consistent feed quality. You should not just change the viscosity or load abruptly.

· Dual Auger vs Single Rotor Configuration

A paddle dryer has two augers. They combine and press sludge continuously. You obtain regular movement and constant goods.

A thin film dryer operates with a single rotor. It only distributes sludge without mixing it back. You have quicker drying and minimal control in making back-mix.

FAQs

What Are the Advantages of the Paddle Sludge Dryer?

You can expect a high energy efficiency, intensive mixing, high drying uniformity, and stable operation. Paddle dryers are also capable of handling sticky sludge.

What Are the Advantages of the Thin Film Sludge Dryer?

For your needs, thin-film dryers provide quick drying speed, high thermal efficiency, and applicability to heat-sensitive or viscous materials because of the short residence time and compact design.

How Does Paddle Sludge vs Thin Film Sludge Price Compare?

Paddle dryers might provide a capital cost per capacity that is lower, particularly for high quantities, while a thin film dryer might carry a high capital cost, but blade maintenance cost is low.

Why Is Sludge Reduction Important in Wastewater Treatment?

Reducing sludge decreases the cost of disposal, minimizes potential dangers such as odors, in addition to increasing the efficiency of the plant.

You also minimize storage requirements, as well as complying with environmental regulations.

Which One Is More Efficient Between Paddle Sludge and Thin Film Sludge?

The thin film sludge dryer is typically more energy-efficient because it has a very high rate of heat transfer.

The paddle sludge dryer is generally more electrically efficient, thanks to the slow speeds involved and low power demand.

What Are the Main Applications of Paddle Sludge and Thin Film Sludge?

You employ paddle dryers in municipal wastewater treatment plants, chemical plants, refineries, and industrial by-product processing plants. You apply thin-film dryers in the pharmaceutical sector, the petrochemical sector, the agro-chemicals, and food-processing waste.

FanQun is your Trusted Dryer Systems Manufacturer in China

FanQun has been designing and manufacturing paddle sludge and thin fil, sludge dryers for over 10 years. At the moment, we have partnered with over 500 waste water treatment companies in both the U.S.A and Europe.

With very sludge treatment equipment, we customize every equipment to meet your unique process needs and specifications – send your dryer design now.