Features of FANQUN ’s Air Heat Exchanger

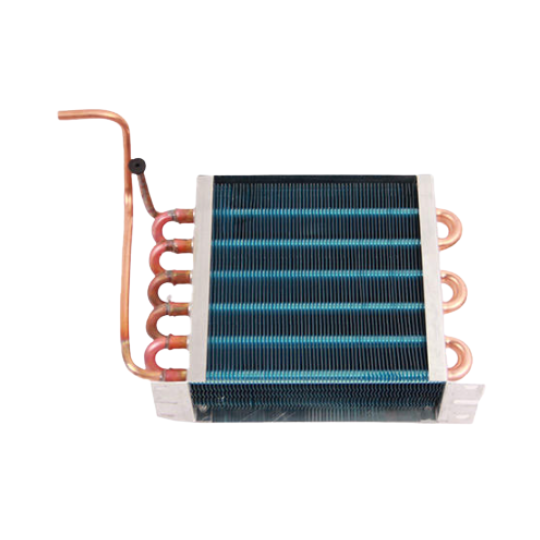

FANQUN ‘s SRZ and SRL spiral fin air heat exchangers use a mechanically wound fin design, providing a large contact area between the fins and heat pipes. This ensures stable and efficient heat transfer performance with minimal airflow resistance, delivering highly effective heating results.

- FANQUN air heat exchangers can achieve heating effects at 150°C.

- Suitable media include steam, hot water, or thermal oil, with steam operating pressure generally not exceeding 0.8MPa.

- The SRZ-type finned tube bundle employs a mechanical winding process where 0.5x10mm steel strips are wound onto 18mm seamless steel tubes. The steel strip or steel pipe can be processed with hot dip galvanizing.

- All FANQUN air heat exchangers have obtained ISO 9001 certification.

- FANQUN has secured ten technical patents, demonstrating reliable professional expertise.

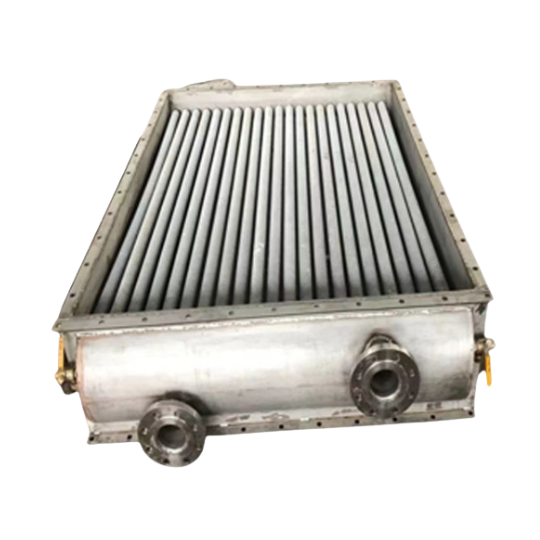

FQ-RJH Air Heat Exchanger

Model SRZ and SRL screw wing radiator manufactured by our company is mainly used for heating air in the system of drying and is mainly drying equipment in hot air device. The conducted heat medium adopted radiator may be steam, hot water or heat conducting oil. In general, the working pressure of steam is not more than 0.8MPa and the temperature of air will be below 150°C.

The wing radiator consists of three rows of paratactic screw wing pipe mainly. The paratactic screw wing pipe is made through winging 0.5×10mm of steel belt onto 18mm steel pipe and then zinc hot galvanized. It can also be made with full stainless steel pipe and belt. Model SRL radiator is made of steel pipe and aluminum belt through rolling. Its radiator area of the same length is more than Model SRZ.

Adopting mechanical wound piece, the contacting area between radiating wing piece and radiating pipe is large and its property of heat conducting is good and stable. The resist for air passing is small. The effect of heating or cooling air can be realized through heat condition between wing on steel pipe and air in the gap and wings.

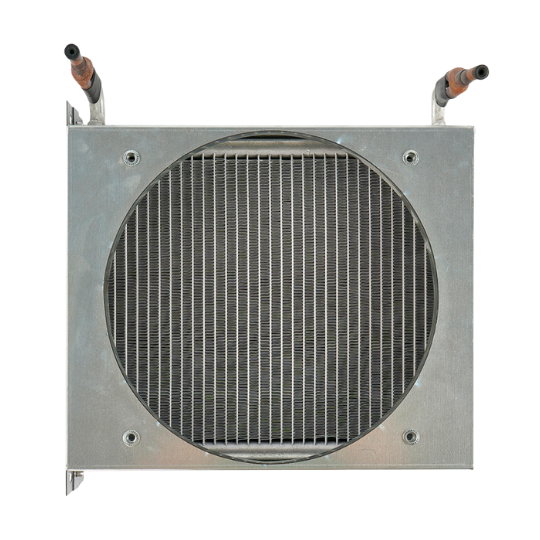

Manufactured with durable aluminum and stainless steel. Corrosion resistant with great heat control.

An eco-friendly and adjustable temperature, has great energy and heat recovery for various applications.

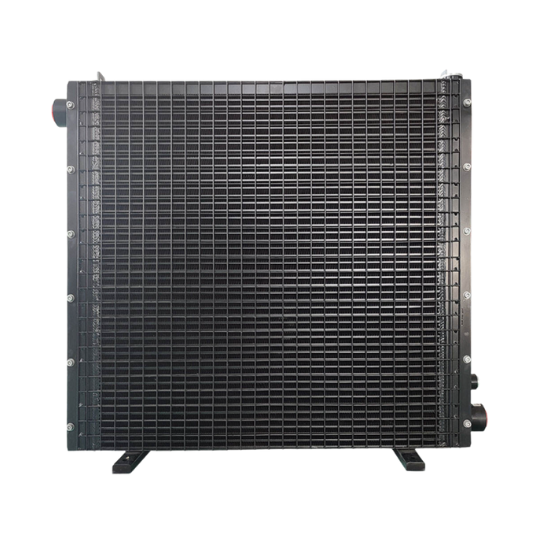

Great cooling control with durable stainless steel, temperature and pressure controlled with hydraulic oil.

Great cooling control with durable stainless steel, temperature and pressure controlled with hydraulic oil.

Great heat application and has great temperature control, Good quality and has great cooling capacity.

Features an excellent environmental control and high-accuracy. Has metal corrosion resistance and is waterproof.

Plate heat exchanger with energy saving feature, High efficiency and temperature accuracy.

Has an excellent energy-saving and aluminum alloy material with aluminum corrosion resistance, enhanced to withstand impact dents.

- Our Factory

- Specification of Fins When The Heat Source is Hot Water or Thermal Oil

| Item | Stainless steel | Carbonaceous steel | Al |

|---|---|---|---|

| Outer diameter specification (mm) | Ø18X2 | Ø19X2 | – |

| Diameter of fin (mm) | Ø38 | Ø39 | – |

| Thickness of fin (mm) | 0.24 | – | 0.4 |

| Factor of heat exchanging area (m²/m) | – | 0.64 | – |

What Is An Air Heat Exchanger?

Air heat exchangers are devices widely used in industrial applications for heat exchange between fluids. They use different media to promote the heat transfer with air to achieve the goal of cooling or heating.

Due to their strong heat exchange capabilities, air heat exchangers currently play a vital role in various fields such as industrial plants and modern buildings. They functions by maintaining the indoor temperatures while reducing indoor pollution. The most common types of them include finned and plate type air heat exchangers, each of them offers distinct heat transfer efficiencies.

FANQUN specializes in manufacturing finned air heat exchangers for heating applications. If you’re seeking a reliable air heat exchanger brand, contact us anytime for a quote.

How Does An Air Heat Exchanger Work?

The operation of an air heat exchanger fundamentally employs the principles of heat transfer and convection. During actual operation, air and the heat transfer medium achieve heat exchange through fins or plates, at the same time, the heat flows from the high temperature side to the other side, thereby achieving the purpose of heating the air. Meanwhile, convection occurs between the air and the heat transfer medium, this further accelerates the heat transfer and enhances thermal efficiency.

More specifically, the medium within the air heat exchanger determines the unit’s operational function. When circulating media such as high temperature steam, water, or thermal oil flow through the equipment, the heat exchanger provides heating. On the contrary, when low temperature air, chilled water or brine circulates internally, it delivers a cooling effect.

Components Of An Air Heat Exchanger

The Main Frame

The main frame of the air heat exchanger serves as the fundamental support structure. It must be stable and robust to bear the weight of the entire unit, thus it requires a coating to provide corrosion resistance to ensure a long service life in demanding environments such as industrial settings.

Fins/Plates

As mentioned earlier, air heat exchangers will be divided into finned or plate type heat transfer elements. Whether fins or plates, both of their functions are to increase the surface area of contact between air and the medium, thereby achieving ideal heat exchanges.

FANQUN offers finned air heat exchangers crafted from stainless steel, carbon steel, or aluminum. These materials deliver exceptional heat dissipation properties, effectively providing indoor heating.

Controlling System

For using and controlling the machine easily, an air heat exchanger is always equipped with a control system. This allows you to monitor the temperature of the medium inside the unit’s chamber in real time and maintain the entire heating or cooling process at a stable state, enabling long term operation within factories or warm air systems.

Advantages Of Using an Air Heat Exchanger For Heating

Energy Saving

The operation of an air heat exchanger involves using the heat source within the heat exchange tubes to come into contact with air, transferring heat to the surrounding atmosphere. Compared to active heating methods, this approach requires less electricity.

The design also can expand the surface area through fins or plates to achieve more thorough contact, thereby enhancing heating efficiency. Furthermore, an air heat exchanger can use residual heat from your industrial production processes to complete the heat transfer cycle. This not only improves energy utilization efficiency but also further reduces your overall energy consumption.

Maintain the Indoors Environment Dry

Air heat exchangers can heat air, this is a function that also helps remove moisture from the indoor spaces. Since damp environments can cause bacterial growth more easily, this ability to keep interiors dry maintains indoor comfort while preventing allergies or other health issues.

Simple Installation And Maintenance

Installing an air heat exchanger is straightforward. You just need to connect the power supply and the piping for the heat transfer medium. These steps won’t take much time.

Moreover, due to its simple operating mechanism, wear and tear on the components during operation is minimal. You’ll hardly need to spend much time or effort maintaining your air heat exchanger, and this results in a lower maintenance cost. In a word, whether it’s installation or maintenance, it’s a machine designed for enhanced operational convenience.

More Safer

In practical applications, the heating method of air heat exchange does not require open flames or high temperature heating. Therefore, it can effectively ensure operational safety in spark sensitive environments such as chemical plants and wood processing facilities.

More Stable

As mentioned earlier, the structure and operation of air heat exchangers are relatively simple. In terms of composition, they contain few complex mechanical components. During the operation, they only require the uninterrupted flow of the heat transfer medium and reduce the frequent wear on mechanical parts. Thus even in prolonged operation, they will maintain stable performance and can continuously deliver heat to indoor spaces.

Where Can An Air Heat Exchange Be Used?

Commercial Constructions

In HVAC systems within commercial buildings, air heat exchangers can assist heating by recovering residual heat from equipment. This enables more energy efficient maintenance of constant indoor temperatures, achieving long term, low energy temperature regulation in shopping malls or office buildings.

Automotive Manufacturing

In automotive manufacturing, the primary function of air heat exchangers is to maintain a dry factory environment. This prevents humidity from compromising machining precision and compromising the efficiency of painting processes. Simultaneously, these systems effectively reuse heat generated by automotive processing equipment, further conserving energy and reducing operational costs.

Food Industries

Within the food industry, air heat exchangers primarily serve to maintain humidity, temperature, and environmental cleanliness within processing plants. For baked goods such as cookies and potato chips, a dry environment is crucial for preserving quality and texture. It also prevents moisture in the air from causing bacterial growth and food spoilage, thereby enhancing safety and hygiene throughout all stages of food processing.

Chemical Industries

Within chemical plants, air heat exchangers play a crucial role by recovering heat from equipment cooling systems for heating purposes. Their stable, flameless operation offers enhanced safety and reliability in these flammable and explosive environments, significantly contributing to the plant’s secure operation.

Agriculture

Air heat exchangers are indispensable across all stages of agricultural production. Take agricultural greenhouses as an example, these devices maintain a constant internal temperature to support year round cultivation. In grain storage, they also dehumidify warehouses, preventing crop mold and ensuring long term preservation.

How To Choose An Air Heat Exchanger?

Heat Transfer Area Coefficient

When selecting an air heat exchanger for your project, the heat transfer area coefficient is a crucial parameter. It represents the effective heat transfer surface area per unit volume or length of the heat exchanger, typically expressed in m²/m. A higher value indicates greater heat exchange capacity. In space constrained conditions, choosing equipment with a larger heat transfer area coefficient achieves superior heating performance. Generally, brand product specifications include this value with accompanying explanations. You may directly contact the manufacturer for confirmation.

To learn more about our finned air heat exchangers, contact FANQUN’s dedicated customer service team for consultation immediately.

Air Volume and Air Velocity

Airflow volume and velocity are also critical factors when selecting ventilation or heat exchange equipment, and their specific values must align with the application environment. Larger spaces require equipment with higher airflow volume and velocity; otherwise, heating efficiency will be compromised. On the other hand, smaller spaces need not employ equipment with excessively high specifications, as overly large airflow volumes may impose unnecessary strain on the heating system, leading to wasteful energy consumption. Generally, an air velocity range of 1.5 m/s to 3 m/s is considered reasonable and offers broad adaptability.

Materials Of The Frame

The thermal conductivity of air heat exchangers is closely related to the materials used in their construction, as different materials exhibit varying thermal conductivity coefficients. Generally, carbon steel offers higher thermal conductivity at a lower cost, making it suitable for most environments. However, in more demanding industrial settings, stainless steel proves more appropriate due to its superior corrosion resistance and durability. It is also better suited for the food industry, where high safety and cleanliness standards are required.

FANQUN is a professional manufacturer of drying equipment in China. With 25 years of production experience in the drying industry and extensive export expertise, we reliably deliver a wide range of high performance products to your region. Regarding product quality and safety, we provide product inspection certificates and ISO9001 certification. Our after sales service includes on site guidance for equipment installation and commissioning, as well as technical training, ensuring you have no worries after the purchase.

Indeed, compared to most industrial equipment, air heat exchangers require simpler and less labor to keep the maintenance. However, this does not mean they don’t need maintenance entirely.

Essential maintenance you need to take include regularly inspecting fins for dust accumulation and checking components for wear. In chemical applications, you must also verify the integrity of pipe connections and inspect the unit for corrosion. One of its advantages is that you don’t need to check it frequently and can prolong the maintenance cycle.

When installing an air heat exchanger, you need to first locate an area with good airflow and ensure sufficient space for future maintenance. Next, you can inspect the unit’s seals and verify the integrity of all components. Finally, you should connect the piping and power supply, configure the operating parameters and modes within the control system, and the unit will be ready for normal operation.

In comparison, fin type air heat exchangers offer a larger surface area, enabling more efficient heat exchange capabilities and achieving higher heating temperatures. They perform better in industrial environments. On the other hand, Plate type air heat exchangers are able to exchange the air in large area and with higher airflow rates, you need to know that they are unsuitable for high pressure or high temperature conditions.

However, it is impossible for us to conclude which type of heat exchanger is superior, the choice depends on your specific application environment.