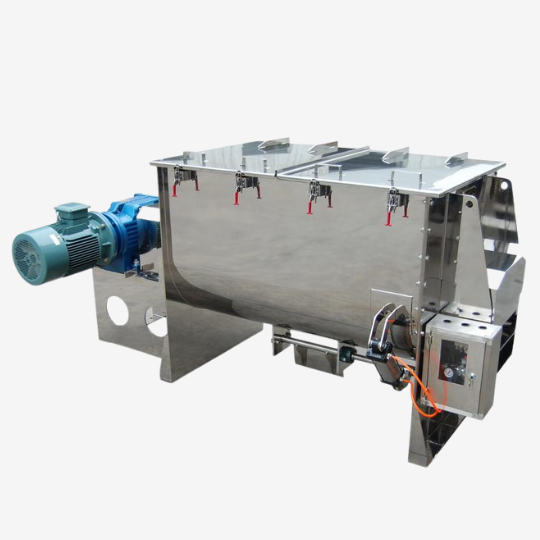

Features of FANQUN Horizontal Ribbon Mixer

The horizontal ribbon mixer delivers high efficiency and gentle mixing to help you produce stable product quality for large batches.

- Stainless steel, fully enclosed design

- No dead corners, easy to clean, complete discharge

- Deal with broad materials, such as particles, powder, and liquid

- Achieve high uniformity in a short time

- Each horizontal ribbon mixer of FANQUN undergoes a comprehensive testing, guaranteeing high performance before delivery

WLDH series Horizontal Ribbon Mixer

The model consists of container, spiral mixing blades and transmission parts; spiral blades are generally made of double or triple, the outer spiral will be the material from both sides to the center of the collection, the inner spiral will be the material from the center of the two sides of the conveyor, the formation of convection mixing. Generally used for viscous or cohesive powder and granular mixing as well as powder and granular add liquid and paste material mixing, due to the machine loading coefficient is large, the equipment covers an area of small and viscous materials cleaning difficulties, suitable for large output, not often change the varieties of occasions mixing.

Screw type horizontal ribbon mixer with customizable maximum production capacity and has a 220-480V.

A customizable voltage industrial horizontal ribbon blenders with high productivity and high accuracy performance.

A putty, paint, and dry materials horizontal ribbon mixer with static mixer type that has a high mixing efficiency.

A brushless motor type horizontal ribbon mixer with a high safety level feature and has a 2-24rmp range of spindle speed.

An automatic stainless steel material horizontal ribbon mixer with a 300-500 liter maximum production capacity per batch.

An easy to operate with high efficiency horizontal ribbon mixer capsule with a customizable size, dimensions, and capacity.

A various material compatible horizontal ribbon mixers with high precision and accuracy feature and has a maximum production capacity of 1000 liters.

A high quality 380V industrial horizontal ribbon mixer with a high safety level feature and a high production capacity.

- Our Factory

- Technical Parameters

| Model | WLDH-0.3 | WLDH-0.5 | WLDH-1 | WLDH-1.5 | WLDH-2 | WLDH-3 | WLDH-4 | WLDH-6 | WLDH-8 | petal |

|---|---|---|---|---|---|---|---|---|---|---|

| Mixed amount (kg) | 100~150 | 200-300 | 400~600 | 600~900 | 800~1200 | 1200~1800 | 1600-2400 | 2400~3600 | 3200~4800 | 4000~6000 |

| Parameter 1 (range) | 1.5-4 | 3-5.5 | 4-7.5 | 7.5-11 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1400 | 1900 | 2500 | 3100 | 3600 | 5300 | 6800 | 7800 |

What is a Horizontal Ribbon Mixer

The horizontal ribbon mixer utilizes a U-shaped cylinder and a double or triple-layer spiral ribbon, pushing materials in opposite directions to achieve uniform mixing in a short time. It can help you increase production capacity, deliver faster, and prevent your materials from degrading.

Suitable for large-scale and long-term operation.

Key Parts of a Horizontal Ribbon Mixer

- U-Shaped Container

It is used to hold powders, granules, or small amounts of liquid materials. The unique shape allows the material to be more easily pushed, turned, and diffused by the ribbon during mixing, thereby obtaining higher mixing uniformity.

It is made of stainless steel SUS304 or SUS316L, and the inner surface is polished to Ra 0.4.

- Ribbon Agitator

The agitator consists of inner and outer double-layer spiral ribbons. The outer spiral belt pushes the material to both sides, while the inner spiral ribbon moves the material towards the center, helping to mix the materials quickly.

For lightweight or highly viscous materials, propeller-type, plow-type, or customized spiral ribbon can be used to improve your mixing effect.

- Drive System

Composed of a motor, reducer, and coupling, it drives the ribbon agitator to rotate stably. A high-quality drive system ensures your equipment can operate for a long time without vibrating or overheating.

According to the characteristics of different materials, frequency converters can also be used for stepless speed regulation to enhance your mixing efficiency.

- Discharge Valve

The discharge valve is used to discharge materials after mixing. And, the discharge port can be flexibly placed in the center or on the side, according to your specific requirements.

Additionally, commonly used pneumatic valves can help you precisely control the discharge speed and reduce material residue, accelerating your production progress. For materials with poor flowability, an arch-breaking device can be added to facilitate unloading smoothly.

- Control Panel

The control panel manages the machine’s operation, involving starting or stopping, timing, speed adjustment, and temperature monitoring. Equipping it with a PLC and touchscreen can help you manage the mixer more easily while significantly improving the mixing line.

- Safety Features

Safety features often include mechanical limit switches, interlocking devices, emergency buttons, overload protection, and tamper-proof protective covers, all of which help guarantee safer and smoother machine operation. Moreover, seals at the machine slots and shaft prevent dust leakage, enhancing your workshop environment and prolonging equipment service life.

Advantages of Horizontal Ribbon Blender

High Mixing Efficiency

The loading coefficient of the horizontal ribbon blender is usually between 0.4 and 0.6, so you can achieve a larger batch output with the same workshop area. At the same time, the counter-current convection of the double ribbons enables uniform mixing in a short time, saving your energy bills and avoiding equipment wear.

Just imagine, when your customers are urging for orders and production capacity is tight, which equipment can help you accelerate delivery without expanding your factory? Undoubtedly, it’s the horizontal ribbon mixer with its highly efficient mixing capabilities.

Borden Materials Handling

Using different equipment to handle materials of varying textures is not only troublesome but also increases your cleaning time and the risk of cross-contamination. Furthermore, if you’re using a high-speed paddle mixer, particles tend to be sheared and broken down.

Fortunately, a horizontal ribbon blender, with its gentle mixing force, minimizes particle breakage, solving this problem effectively. And the liquid spray system helps you mix powders and liquids without localized clumping.

One machine can deal with various formulations, decreasing the cost of purchasing additional equipment and the time for changing machines.

Comply with Hygiene Standards

If there are dead corners inside the mixer, it’s difficult to clean and easy to trigger cross-contamination, which may cause customer complaints.

To solve these problems, our horizontal ribbon mixer applies a fully welded process, a detachable, polished stainless steel tank. The gap between the blades is also precisely controlled, ensuring a smooth interior without accumulation points, so you can discharge the material quickly.

Meanwhile, a double-sealed design prevents dust escape, protecting the bearings and your workshop environment. The large cleaning door enables you to easily clean the interior, and with the optional CIP system, cleaning will be even more convenient, saving your time and costs.

Customizable

Our horizontal ribbon mixer supports a variety of customized functions, including the addition of heating/cooling jackets and optional explosion-proof motors.

Perfer enhance automation? It can be equipped with a weighing system, automatic feeding, and PLC control, reducing your employment costs and errors.

Therefore, it can perfectly integrate into your existing production line. Rather than buying a device that is frequently restricted, it’s better to choose a mixer that is tailored to your process. After all, equipment serves the process, not the other way around.

How to Select a Horizontal Ribbon Mixer

Volume

The optimal loading factor for a horizontal ribbon mixer is 60% of its total volume. Overloading will reduce mixing uniformity, while underloading wastes energy and increases equipment costs.

You can choose the volume according to your batch production, material bulk density, and other mixing needs.

For instance, if you need to mix 300 kg of powder in each batch and the bulk density is approximately 0.6g/cm³, a mixer with a capacity of 800–1000 L is recommended to ensure sufficient turning space. And, reserve 10–20% of the capacity as a margin for future expansion.

Ribbons Number

The double-ribbon configuration is very popular. The outer ribbon pushes to one side, while the inner ribbon pushes in the other direction, producing bidirectional flow, suitable for mixing powders and granules. The triple-ribbon mixer with an additional central ribbon, providing stronger shear and propulsive forces, is suitable for materials that are difficult to mix or have significant differences in weight.

If your material is fragile or requires gentler mixing, consider a hybrid mixer. This combines ribbons with impellers, providing both conveying and gentle agitation.

The more agitators you have, the higher the horsepower required; therefore, you should balance the mixing uniformity and energy use.

Material Characteristics

For heavier materials such as metal powders, choose a machine with a stronger structure and higher horsepower. Lightweight powders like expanded powder, on the other hand, it is best to install an arch-breaking device to avoid bridging and dead corners. You can also select a mixer with an anti-stick inner wall or a higher drive force to handle materials that are prone to clumping and sticking.

Horsepower

Poor horsepower can lead to starting difficulties, uneven mixing, and accelerated gear wear, but excessive horsepower will increase the energy expenses.

Wider ribbons and higher material densities require greater horsepower. Generally, 7.5–15kW is sufficient for lightweight powders. For heavier materials or contain liquids, 18.5–30kW or even higher is recommended.

You had better maintain a 10–20% power redundancy to handle material fluctuations and long-term load variations.

Discharge Valve

Full-length Drop Bottom Gates

It can open almost completely when operating, so it discharges material fast with minimal residue. It is ideal for factories with high production volumes and frequent batch changes. However, slight powder leakage may occur if the seal is poor, so you should choose reliable sealing strips and pneumatic actuators to prevent it.

Pneumatic Slide Gates

The pneumatic slide valve has a sliding structure. It can open partially, and the materials will fall gradually. And it is ideal for packaging lines and weighing systems. It also offers good sealing, reducing the risk of powder leakage.

But you should note that the slide valve outlet is relatively narrow. And, if the material contains particles or is prone to clumping, it may cause blockage.

Knife Gate Valves

If you are working with dry powders, solid additives, or similar materials, a knife gate valve is the preferred choice. It cuts the material with a sharp gate and can discharge them quickly, with low cost and easy maintenance. But it is not suitable for mixing wet or fibrous materials.

Ball Valves

Ball valves usually have a small discharge port and are often used for small-scale, precise material feeding or materials requiring a complete seal. The disadvantages are slow discharge speed and a tendency to jam when facing larger particles. They are well-suited for customers with high hygiene requirements or materials with high costs.

As an equipment manufacturer, we have been engaged in this for over 40 years. Our horizontal ribbon mixer has obtained ISO9001 certification and supports customization to meet your requirements for materials and production volumes. Contact us now, and you will get a competitive offer.

Vertical ribbon mixers are suitable for small-scale material processing in confined footprints and perform well for lightweight powders.

On the other hand, horizontal ribbon mixers are often used for large-scale continuous production, offering faster mixing efficiency and higher uniformity. It can handle powders, granules, and small amounts of liquid.

Ribbon mixers are widely used in the food, chemical, feed, cosmetic, and pharmaceutical applications. It can be used for blending additives and flour, preparing powders, and mixing pharmaceutical excipients. Using a ribbon mixer can significantly increase speed and output in these applications.

Generally, the machine needs CE certification and ISO 9001. The food industry requires the FDA, and the pharmaceutical industry may require GMP or cGMP-related certification. ATEX or explosion-proof rating certificates may also be needed in some cases.

Uniform mixing often takes 5-10 minutes, and sometimes even 2-3 minutes to achieve the desired effect. However, it should be noted that over-mixing may cause material separation. Therefore, the best time should be determined through testing to balance the efficiency and quality of the product.

Of course. However, you had better reduce the stirring speed or use a special coating, like a PFA liner, to lower the risk of breakage.