FANQUN Spray Dryer Granulator

FANQUN provides spray dryer granulators that enable rapid mixing, granulation and drying within a single container, helping you shorten the production cycle and enhance batch stability.

- Flexibly handle different types of product, including solutions, suspensions, or paste-like materials, making you effortlessly meet diverse product formulation and process requirements.

- Effectively controls final product moisture content, particle size distribution, and flowability, keeping consistent quality standards for every batch.

- Supports customized spray drying solutions encompassing atomizing nozzle design, airflow patterns and powder recovery systems, enabling machines better aligned with your production processes.

- Constructed from 304 or 316L stainless steel and combined with reinforced insulation and wear-resistant design to offer long-term stable performance under continuous operation.

- Provide you a one-stop service covering equipment selection, process confirmation, installation and commissioning, as well as operation training.

YPG series;PGL-Bseries Spray Dryer Granulator

The set is an apparatus that can finish drying and granulating at the same time. The needed ball granule with certain size and ratio can be got in accordance with requirements of process by adjusting pressure flow and size of atomizing hole.

The working process of the set is as follow: the liquid of raw material is pumped through high-pressure pump, the liquid of raw material atomizes to small drops, then it gathers with hot air and falls off. Most parts of powder material will be collected through the outlet of discharge at the bottom. The wasted air and fine powder will be separated through cyclone. The waste air will be exhausted through draught fan and powder will be collected at the bottom of cyclone. At the outlet it can also be equipped with two grades of duster. Its ratio of recovery will be over 96%-98%.

The tower body, pipes, separator of the set which will contact with raw material are made of SUS304. There is enough layer of heat preservation between inner and outer of tower body. The filled material is fine glass cotton. The tower body is also equipped with observation door, sight glass, lamp-house and control instruments that are controlled and displayed through electric control panel.

The heat source of the set may be steam or electric heater. Its features are convenient in operation, quick in start, compact structure, clean of hot air and so on. Moreover being installed control and regulating device inside electric control cabinet, the inlet temperature can be controlled through stepless regulation. The steam, coal fuel can be applied to the place where has not electricity. It can replace electric heating locally or fully. The factory can provide different heating method in accordance with the practical condition of customer.

Application of YPG series;PGL-Bseries Spray Dryer Granulator

- Chemical industry: organic catalyst, resin, synthetic washing powder, oils, thiamine, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

- Foodstuff: Amino acid and similar substances, flavoring, protein, starch, dairy products, extractive from coffee, fish powder, extractive from meat and so on.

Pharmaceutical: Chinese traditional medicines, pesticide, antibiotic, medical drinking and so on. - Ceramics: Magnesium oxide, kaoline, all kind of metallic oxide, dolomite and so on.

- Granulating through atomizing: All kinds of fertilizer, aluminum oxide, ceramics powder, pharmaceutical, heavy metallic super hardness steel, fertilizer, washing powder, Chinese traditional medicines and so on.

- Chemical industry: organic catalyst, resin, synthetic washing powder, oils, thiamine, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

Features of YPG series;PGL-Bseries Spray Dryer Granulator

- The drying speed is fast, the surface area of raw material liquid after atomized will be increased greatly, 95%-98% of moisture can be evaporated at moment, the time of drying needs about ten seconds to several-tens seconds, it is suitable for drying material particularly.

- The finished product is ball granule with uniform size, its fluidity and solubility are good, the purity of product is high and its quality is good.

- Its applied scope is wide. According to the characteristics of raw material, it can use hot air to dry or use cool air to granulate, it has strong adaptability to raw materials.

- Its operation is simple and stable, control is simple and convenient, and easy to realize automatic operation.

A large scale centrifugal granulator with great drying and temperature control, spray dryer with various applications.

Steam heating method with scratch-resistant polished surface, Chemical and food processing granulator.

Has great temperature control, Built with stainless steel and largely on industrial use with electric heating method

Can be applied for liquid food and fertilizers, Has great gas and electric heating. Has a high safety level with great granulation.

A great multi-functioning control for drying with cycle, using electricity as heating method for temperature control and ensures low energy consumption.

Has great productivity and is manufactured with motor core components, Heating source is steam, electricity and gas.

Chemical processing and great steam heating method for granulation to drying, low energy consumption and great high efficiency record.

Has equipped with a fluid bed dryer, Most applicable for the chemical industry. Granulation has cycles for thorough drying.

- Our Factory

- Technical Parameters

| Model | Evaporated Amount (kg/h) | Diaphragm pump Power (kW) | Diaphragm pump Pressure (MPa) | Heating way | Diameter of tower body (mm) | Total height of equipment (mm) |

|---|---|---|---|---|---|---|

| YPG-25 | 25 | 0.35 | – | Electricity | 1300 | 7800 |

| YPG-50 | 50 | 4 | – | Electricity+steam | 1800 | 9200 |

| YPG-100 | 100 | 7.5 | – | – | 2400 | 11600 |

| YPG-150 | 150 | 11 | It can be regulated from 0.6 to 5, and generally, it will be from 1 to 3. | – | 2600 | 14000 |

| YPG-200 | 200 | 15 | – | – | 2800 | 15300 |

| YPG-300 | 300 | 22 | – | Electricity+coca fuel(oil) hot air furnace | 3200 | 17100 |

| YPG-500 | 500 | 30 | – | – | 3800 | 19000 |

Working Process of Spray Dryer Granulator

Spray drying granulation directly converts liquid materials into solid particle powder within a system. The entire process consists of three core steps: atomization, rapid drying, and particle formation.

Preparation: The liquid materials need to be adjusted in advance to the concentration, viscosity and temperature suitable for spraying to ensure stable atomization effect and high drying efficiency.

Atomization: Materials are dispersed into small droplets of tens of microns through nozzles. You can choose different methods such as high-pressure nozzles, rotary atomizers or dual-fluid nozzles according to your process to meet different rheological properties and particle size control requirements.

High-temperature drying: After being heated to the set value by the heater, the air enters the drying tower and comes into full contact with the atomized liquid droplets. Moisture evaporates rapidly within seconds (usually from 5 to 30 seconds), and the material is dried at a low retention time.

Particle formation: After drying, solid particles gradually form in the airflow, and it controls the final particle size through collision and adhesion between particles or layer-by-layer deposition on seed nuclei. The typical particle size range can be stabilized at 20-500 μm to meet your different formulations requirements.

Collection: The particles are separated from the airflow by devices such as cyclone separators and bag filters and then collected to the finished product silo. The exhaust gas enters the dust removal and purification system to ensure compliance with environmental protection emission requirements.

Advantages of Spray Dryer Granulator

Single-step Continuous Operation

The spray dryer granulator can achieve evaporation, drying and granulation continuously in the same equipment, which reduces intermediate transfer steps, improving the overall production line efficiency, and lowering your labor and environmental risks.

Fast Drying Speed

The droplet has a huge surface area, which enables water to evaporate rapidly. This entire drying process is usually completed within 5 to 30 seconds. It is conducive to increasing production capacity and avoiding degradation of heat-sensitive materials due to prolonged exposure to thermal cycling.

Precise Quality Control

You can precisely adjust the final moisture content of the particles (the moisture content of the finished product is usually ≤0.5% – 5%), particle size distribution and morphology by precisely adjusting the inlet air temperature, atomization method, airflow path, and drying curve. This ensures your product keeps the stability and consistency in each batch with good fluidity.

Uniformly sized particles and easy to handle

The production particles show a concentrated distribution and good fluidity, which is convenient for transportation, packaging and storage. And they can significantly improve the stability of subsequent processes (such as mixing, tablet pressing and filling).

Lower Cleaning Cost

The structure of the spray system is simple and the nozzles are easy to disassemble and clean. It can also require lower water consumption, the decreasing cleaning chemicals consumption and the shorter downtime of equipment. This machine is suitable for industries with high hygiene requirements.

Extensive Material Compatibility

The spray dryer granulator can process heat-sensitive materials such as dairy products, enzyme preparations, and plant extracts, and is also suitable for various raw materials in different states such as solutions, suspensions, and pastes.

Types of Spray Dryer Granulator

Laboratory Spray Dryer Granulator

It is mainly used for research and development, formula testing and small-batch trials. The laboratory spray dryer granulator offers more flexible temperature control and more delicate atomization adjustment, it is suitable for you to optimize parameters and develop products.

Co-current Spray Dryer Granulator

The materials and hot air flow in the same direction. As the hottest air comes into contact with the wettest particles, it can effectively protect the activity of heat-sensitive materials and is suitable for products such as food additives, flavors, heat-sensitive drugs, and probiotics.

Counter-flow Spray Dryer Granulator

The atomized material and the hot air flow in opposite directions. The counter-flow design maximizes thermal efficiency, which is extremely high. However, it exposes the dried particles to the hottest air to make it more suitable for high-temperature resistant and non-heat-sensitive materials such as inorganic salts, ceramic powders, or some chemical products.

If you need low energy efficiency and the material does not have high requirements for thermal stability, the counter-flow structure is your ideal choice, as it can effectively reduce operating costs.

Closed-loop Spray Dryer Granulator

It uses Inert gases (such as nitrogen) as the drying medium, which is then cooled, dehumidified and recycled. Closed-loop spray dryer granulator can safely handle flammable and organic solvent systems, reduce oxidation risks, protect oxygen-sensitive components, and is suitable for solvent-containing formulations, apis, intermediates, highly active materials and high value-added products. This machine is usually used for handling organic solvents or hyperoxygen-sensitive products.

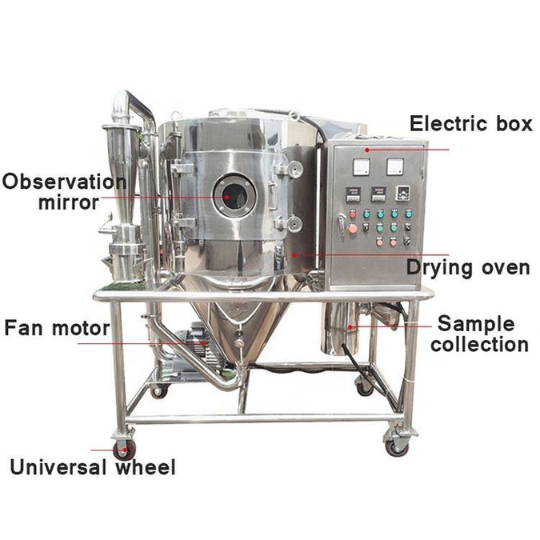

Parts of Spray Dryer Granulator

Feeding system

The feeding system transfers the liquid solution to the atomizer at a stable and controllable rate.

Atomizer

The atomization effect determines the productions’ particle size, shape and moisture content of the particles.

Centrifugal atomizer: Under the action of centrifugal force, the liquid forms a film and breaks into uniform droplets. Centrifugal atomizers are suitable for high-viscosity materials, with uniform particle size distribution of the products. They are commonly used atomization methods in most medium and large-scale production lines.

Pressure atomizer: The liquid passes through a small hole nozzle under high pressure (usually 2-20 MPa) to form a conical spray. The pressure atomizer has a simple structure and relatively low energy consumption, but the nozzle is prone to wear and requires regular maintenance. So pressure atomizers are more suitable for solutions with low viscosity and good fluidity.

Air flow atomizer: It uses high-speed air flow (usually compressed air or steam) to tear liquids into fine mists. Air flow atomizers are more suitable for atomizing materials with high viscosity or containing solid particles, but they show relatively high energy consumption.

Drying Chamber

The material is fully in contact with hot air to complete the drying and granulation in the drying chamber. The working temperature is generally between 80 and 300°C and you can precisely set according to the heat sensitivity of the material.

Heating System

This system heats the incoming air to the required drying temperature. They are commonly used heating methods including steam, heat transfer oil or electric heating.

You can choose the appropriate heating method according to your needs.

Powder Collection System

The collection system can separate dry powder from the airflow, typically using cyclone separators, bag filters or electrostatic precipitators. Among them, the most commonly used one is the cyclone separator, which separates powder from the airflow by utilizing centrifugal force.

For very fine or high-value products, you can use bag filters for efficient recovery.

Auxiliary system

Waste gas treatment system: This system filters and purifies the tail gas to ensure your production meets environmental protection requirements and maintains a safer operating environment.

Heat recovery system: It recovers the residual heat in the exhaust gas and uses it to preheat the intake air, which can significantly reduce your energy consumption. This is suitable for production lines that pursue low operating costs.

Control system: Control system can monitor and regulate key process parameters such as temperature, feed rate, atomization pressure, inlet/outlet air temperature, and so on during running. Some advanced systems can display functions such as formula management, trend analysis, and fault diagnosis, which help you more easily to maintain consistent product quality in production.

Technical Specifications of Spray Dryer Granulator

| Type | spray dryer granulator | heating method | Gas Heating, Electric Heating, Steam Heating |

| Pellet Diameter | 5μm~5mm | Certification | ISO9001 |

| Primary Material | 304、316L | Application | Pharmaceuticals, Food, Chemicals |

| Moisture Removal Rate | 95—99.5% | Principle | From liquid to powder |

| Hot air temperature | 80-300 ℃ | Warranty | 1 year |

| Temperature Control Accuracy | ±1℃ | Atomization Methods | Centrifugal, Pressure, Airflow |

| Feed rate | 1-5000 L/h | OEM/ODM Service | Provided |

How to choose Spray Dryer Granulator

Material Characteristics

Before selecting equipment, you must first identify the key characteristics of the material to choose the appropriate atomization method, tower structure, and hot air distribution pattern. Parameters to consider include: viscosity, solid content, heat sensitivity, and whether the material contains fibers or abrasive particles.

For example, if material is high viscosity, it is recommended for you to choose a spray drying granulator equipped with a centrifugal atomizer.

Product Specification

You also need to clear the quality requirements of the product, such as the particle size range, the uniformity of moisture content, etc. All of these directly affect your machines’ configuration.

Production Capacity

Capacity planning determines the core specifications of the equipment, including the size of the tower body, evaporation capacity, air volume configuration, etc.

So if its application scenario mainly involves research and development, you should choose experimental equipment, which is more convenient for adjusting process parameters.

Cost

There are significant differences in energy consumption among different atomization methods and hot air systems.

If you are concerned about long-term operating costs, you may give priority to models equipped with a heat recovery system. Heat recovery adopts the waste heat from exhaust air to preheat the intake air, which can significantly reduce the consumption of steam or electricity and is particularly suitable for factories with continuous production.

Spray dryer granulator rapidly convert liquid materials into uniformly sized, free-flowing granular products. They can enhance product quality and also effectively reduce energy consumption and operational costs so that they are widely applied in the food, pharmaceutical, and chemical industries.

FANQUN offers one-stop services from process evaluation and equipment selection to installation and commissioning, which delivers equipment’s performance aligns perfectly with your production requirements. So it is time to contact us to get your customized spray drying granulation solution.

The equipment can handle a variety of liquid materials, including heat-sensitive solutions, suspensions and systems that require one-step powder or granular production, such as food ingredients, plant extracts, fine chemical raw materials, ceramic slurries and pharmaceutical intermediates, and so on.

Yes. For solvent-containing materials, we usually recommend a closed nitrogen circulation system with a high-efficiency condenser to reduce the risk of explosion and increase the solvent recovery rate at the same time.

We can provide on-site installation, commissioning, process validation and operator training at the factory to ensure your equipment smooth launch and stable operation.