FANQUN Double Cone Rotary Vacuum Dryer

FANQUN double cone rotary vacuum dryer helps you dry materials efficiently without destroying their structure.

- High sealing maintains a stable vacuum environment, preventing bacterial contamination.

- Gentle tumbling motion of 4-6rpm protects the crystal structure of the material.

- Vacuum low-temperature drying avoids surface hardening.

- Solvent recovery unit saves energy.

- Comprehensive cleaning and sterilization system.

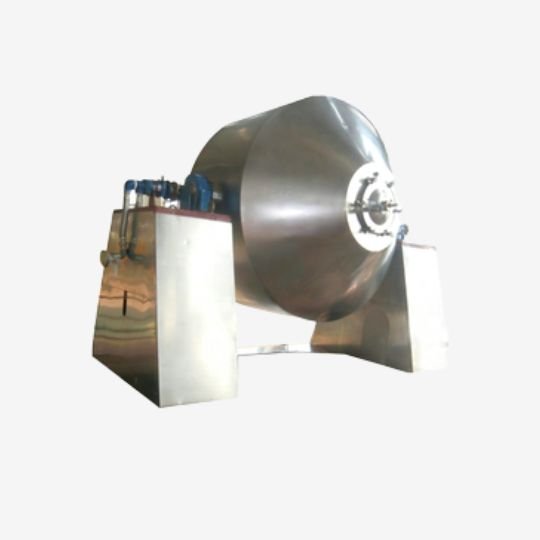

SZG Series Double Cone Rotary Vacuum Dryer

The main body of SZG series double cone coating vacuum dryer is double cone tank.Inside tank, it always keeps at vacuum situation.steam or hot heat water can be passed in jacket which can heat the internal bladder.heat through jackets passed to wet raw material.It’s makes moisture evaporated.low speed electric engine drives tank to rotate.material are moved up to down and actived inside to out outside hot area are changed instantly.meanwhile.water steam are continually drew out through vacuum pump and vacuum air discharge pipe, this improves the drying speed and achieves aim of average drying.It’s satisfy pharmacy management standard GMP.

Features of SZG Series Double Cone Rotary Vacuum Dryer

- Drying process in vacuum environment.It has high speed under low temperature,compared to normal drying method,drying speed is improved two times.Energy are saved.heating efficiency is high,this equipment especially suit for heating sensitive material and easy oxidiated.

- This equipment has developed design.inside structure is simple,easy clean.dried material can be discharged totally,operation is easy.

- Sealed drying.products can not be damaged.no pollution.It’s suit for strong simulative and poisonous material.

- Material is rotated and mixed to dry,this can make moisture totally dried.keeps good average condition and suit for various material’s requirements.

- Compacted structures,small occupied area,simple operation,labor strength is reduced and saved.

- Customer can select step-less regulation(1~10r/m) and step regulation (6~10r/m),it’s easy to adjust drying capacity and adopt to different requirement.

Rotating and mixer installed for granulation auto-blending, Available for chemical production and food processing. Very versatile and customizable.

Manufactured with carbon steel and heat sources are steam and electricity. Very versatile and customizable.

Deals with thick materials and suitable for chemicals, plastic and food. Long lifespan enhanced by durable and anti-erosion manufactured exteriors.

Versatile on applications as it suits every product. Features ideality of vacuum dryers, Automatic and Continuous usage.

Speed and temperature control is adjustable for preferable results. High-quality material evaporates moisture.

Wide versatile application for chemical processing, Steam heating method that does not require load of energy.

Commonly used for food production with switchable rotation. Electric heating method and adjustable pace and temperature.

Homogenizer mixer with granulation capability, Sealable bottom-entry with multifunctional additions from vacuum drying to mixing.

- Our Factory

- Technical Parameters

| Model | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Volume inside of tank (L) | 100 | 350 | 500 | 750 | 1000 | 1500 | 2000 | 3500 | 4500 | 5000 | 8000 |

| Practical loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 | ≤4000 |

| Rotary speed (r.p.m.) | 3~13 | 6 | 5 | 4 | 4 | 4 | 3.5 | ||||

| Power of motor (kw) | 0.75 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 37 |

| Occupied area LxW (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 | 4400×2500 |

| Rotating height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 | 2940 | 2990 | 3490 | 4100 | 4200 | 4900 |

| Design pressure inside of tank (MPa) | -0.1~0.15 | ||||||||||

| Design pressure of jacket (MPa) | ≤0.3 | ||||||||||

| Working temperature (°C) | In the tank≤85, Jacket≤140 | ||||||||||

| Model and power of vacuum pump | SK-0.4 1.5KW | SK-0.4 1.5KW | SK-0.8 2.2KW | SK-1.5 4KW | SK-1.5 4KW | SK-3 5.5KW | SK-6 11KW | SK-6 11KW | SK-9 15KW | SK-12 18.5KW | SK-15 22KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 | 3300 | 3600 | 6400 | 7500 | 8600 | 10000 |

Remark: For raw material, if its volume has great change before and after dry, then its filling coefficient may be increased or decreased suitably.

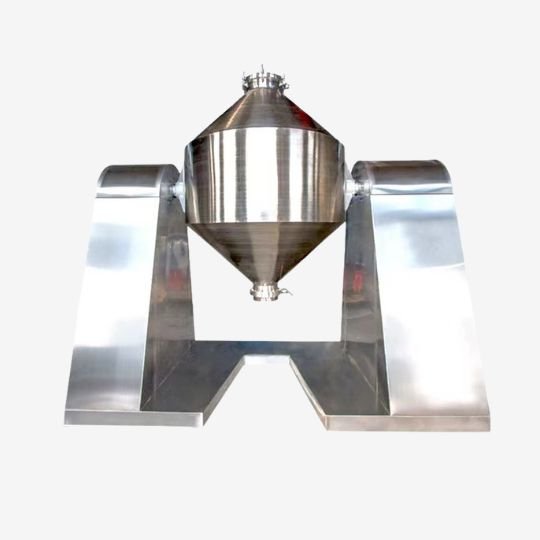

Definition of Double Cone Rotary Vacuum Dryer

It is a vacuum dryer featuring two conical ends. The heat is transferred to the material by injecting conductive media into the interlayer. The drying process is achieved through continuously tumbling and heating in a vacuum environment.

Working Principle of Double Cone Rotary Vacuum Dryer

A vacuum pump is used to remove air from the tank to create a vacuum environment, thus lowering the vaporization point of water. Then, the heating medium is injected into the interlayer to heat the material. When the tank rotates, materials are constantly thrown up and down and fully exposed to the vacuum environment, which accelerates moisture evaporation. The water vapor is then sucked away by the vacuum pump.

Parts of Double Cone Rotary Vacuum Dryer

Conical Body

The body is made of a compact cylinder and two symmetrical cone apex angles. The angle between the two cones is typically 90 ° to 60 °, and it can be flexibly selected according to the material’s slip angle. When stacking materials, the angle between the stacked materials and the inner wall of the bottle should not exceed the sliding angle; otherwise, the materials may slide down from the sides.

The main shafts at both ends of the cone are welded to the cone as a whole, and finite element analysis was performed on the design of the connection points, ensuring they are unlikely to deform when rotating. The shaft end sealing structure uses a double-layer Teflon material and a metal elastic conformal seal to ensure zero leakage and a vacuum environment.

The outer wall of the body is made of stainless steel. The insulation layer inside the body is made of aluminum silicate, which is more environmentally friendly and energy-saving than fiberglass wool.

The frame supporting the cylinder is made of channel steel and carbon steel plate, with an outer stainless steel cladding, ensuring stability at high speeds.

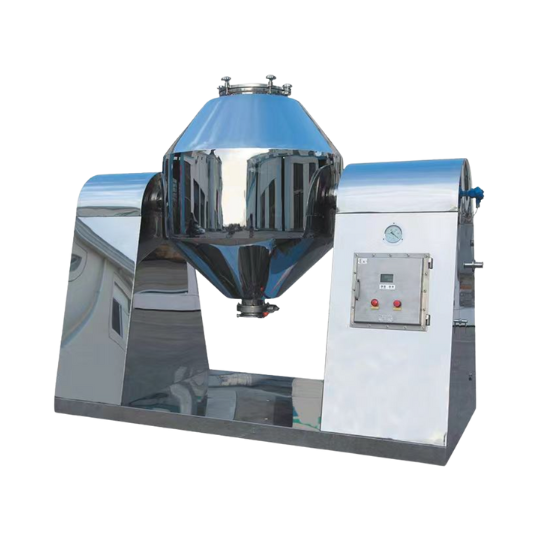

Heating System

The heating materials include hot water, hot oil, and steam. All of them are in the interlayer inside the cylinder. One type of electrically heated double cone rotary dryer has the power switch enclosed on the outside of the cylinder. Our temperature controller is equipped with an advanced PID intelligent algorithm, which keeps the temperature difference within ±1℃, suitable for heat-sensitive materials.

Vacuum System

Generally, the higher the vacuum level, the lower the vaporization point of water. However, excessive vacuum not only hinders heat transfer but also increases costs. We adjust the vacuum level according to the temperature that the material can withstand. The speed of the vacuum drying is twice the speed of common drying, so it has a high thermal energy utilization rate, reaching over 85%.

The vacuum pump provides a stable negative pressure and can also remove water vapor. After drying is complete, a vacuum environment needs to be filled. To avoid damaging the vacuum system, the air valve should be adjusted carefully during emptying.

Condenser

The condenser cools high-temperature solvent vapor through cooling media. When the high-temperature vapor is extracted by the vacuum pump, it contacts the low-temperature tube wall and condenses into a liquid, thus. This process recovers the solvent and is energy-saving and environmentally friendly, especially for expensive organic solvents such as ethanol, acetone, and dichloromethane.

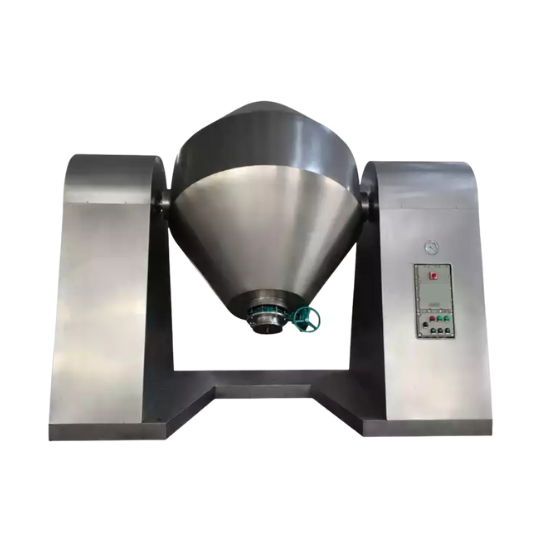

Control System

The control system monitors the operating status of each component and makes timely adjustments to keep fluctuations of temperature and pressure within the set range. This helps the components work together effectively and improves overall drying efficiency.

CIP and SIP Units

The CIP unit mainly consists of an acid tank, an alkali tank, a water tank, a pump set, a heat exchanger, and sensors. During cleaning, the CIP system seals the pipes and uses cleaning agents such as sodium hydroxide and nitric acid to clean the inner walls of the dryer. It can remove microorganisms and material clumping.

Our CIP unit is designed according to GMP standards. After cleaning, we use total organic carbon and conductivity to test the cleaning effect. It has a shorter cleaning time, and the automatic cleaning also reduces labor costs. The media of the SIP sterilization unit are hot water and steam, which are prepared from RO water, ensuring that these media are free of impurities and salts.

During cleaning, CIP cleaning should be performed first, and the next step is SIP sterilization. This order ensures that microorganisms hidden in the dirt can be completely eradicated, guaranteeing that our dryer meets GMP international standards. Also, the cleaning speed of the two units is 40% faster than traditional manual cleaning.

Applications of Double Cone Rotary Vacuum Dryer

The dryer provides a sealed vacuum environment with low oxygen content, which prevents denaturation of easily oxidized materials.

Its high sealing and leak-proof properties prevent bacteria, which are suitable for drying strongly irritating and toxic materials.

The low drying temperature is friendly to heat-sensitive materials.

The double cone rotary vacuum dryer doesn’t have an agitator that can generate shear force, and it is equipped with a gentle rotation speed, which makes it suitable for materials requiring a precise crystal structure and having a strict limit of metal ions.

Pharmaceutical Industry

Active pharmaceutical ingredients of Western medicine: Antibiotics, protein drugs, and sterile raw materials. They have high requirements for hygiene standards. Our SIP device can thoroughly sterilize.

Traditional Chinese medicine extracts: Astragalus, Salvia miltiorrhiza, fish bile, and snake venom extracts. To maintain the active ingredients in the extracts, the drying temperature should be low.

Intermediates: Particle intermediates that require maintaining a specific particle size distribution. The rotation speed as low as 4 rpm ensures that the crystal structure of the particle intermediates remains undamaged.

Chemical Industry

High viscosity polymers: Polyvinyl alcohol (PVA), polyacrylamide. High viscosity polymers have poor liquidity. You can preprocess these materials, avoiding clumping caused by localized overheating during the drying process.

Hazardous chemicals: Explosives and petrochemicals. The dryer that dries these chemicals must be cleaned, preventing other residual substances from reacting with the chemicals. Also, the temperature should be controlled to prevent an explosion.

Fine chemical intermediates: Dyes, pigments, catalysts, rubber, and plastics. These products require a stable environment for storage.

Basic chemicals: Organic and inorganic compounds.

Foods Products

When drying foods, maintaining nutrition and flavor is important.

Dehydrated products: Dried fruit, dried meat, and dehydrated vegetables. Drying prevents these foods from molding, extends their shelf life, and preserves their nutrients and flavor.

Dairy products: Milk powder, cream. Temperature control can prevent protein denaturation and fat oxidation.

Functional food ingredients: Probiotics, dietary fiber, vitamins, and minerals. Our dryers can achieve stable drying at temperatures below 40°C, ensuring temperature fluctuations are less than 1°C.

FANQUN has 32 years of experience in manufacturing drying equipment, and can solve any material drying problem for you. Our double cone rotary vacuum dryers strictly implement GMP standards and continuously absorb new technologies to evolve with industry needs. Contact us now to get your material drying solution for free.

FANQUN has 32 years of experience in manufacturing drying equipment, and can solve any material drying problem for you. Our double cone rotary vacuum dryers strictly implement GMP standards and continuously absorb new technologies to evolve with industry needs. Contact us now to get your material drying solution for free.

Materials with high viscosity are easy to clump or stick to the inner wall of the dryer. Even if the materials are dried and discharged, there is a certain chance that they will stick to the inner wall. You can use a crushing device or a pneumatic vibration method to pre-process these materials.

Except for the appearance differences, the double cone vacuum dryer doesn’t have an agitator and mixes materials by the rotation of the cylinder itself.

Its rotational speed is faster than other dryers. Different rotational speeds are used for different stages of the drying process. In the initial stage of drying, the rotational speed is lower to prevent clumping and adapt to the high viscosity and moisture content of the material. In the middle stage of drying, when the material is drier, the rotational speed is increased to shorten the drying time.

We use steam sterilization cleaning because of the non-removable cylinder of the double cone rotary vacuum dryer. When cleaning, we switch the vacuum line and add pressurized cleaning water to the rotating cylinder. For sterilization, we use a SIP (Sterilization-In-Place) device.

An incomplete discharge can easily damage the inner wall of the cylinder. If the materials are acidic or alkaline, they can more easily cause the inner wall to peel off and shorten its service life. Therefore, we construct the inner wall from corrosion-resistant stainless steel, and it is polished without dead corners.

Pretreatment can effectively improve drying speed and reduce material loss.

If the material particles are too large, appropriate crushing or granulation treatment should be performed.

If the viscosity is too high, anti-sticking agents such as talc should be added.