FANQUN Vacuum dryer

FANQUN delivers efficient vacuum dryers suitable for a wide range of materials.

- Handle diverse materials including powders, pastes, and viscous suspensions, particularly suited for highly viscous, heat-sensitive, solvent-containing products.

- Offer multiple types of vacuum dryers for selection and customized solutions based on your process parameters and capacity requirements.

- Shows a long structural lifespan, high safety standards, and controllable operating costs, meeting sustainable production needs.

- Manufactured in compliance with GMP requirements and undergoes comprehensive performance, safety, and reliability testing.

- Provide 24/7 technical support and comprehensive after-sales service to ensure your production line keeps stable and long time running.

The machine is built on vacuum freeze drying principle, it has compact conformation, convenient maintain, low price, full automatic control and convenient operation.

Blending shaft can rotate reversed So incide of chamber pulpiness, paste-like mixture or powder raw materials can be uniformly dried.

Drying process in vacuum environment.It has high speed under low temperature,compared to normal drying method,drying speed is improved two times.

Material is rotated and mixed to dry,this can make moisture totally dried.keeps good average condition and suit for various material’s requirements.

This equipment has developed design.inside structure is simple,easy clean.dried material can be discharged totally,operation is easy.

Enclosure vacuum dryer chamber with great dehydrating function, Temperature is adjustable and made with explosion-proof stainless steel.

Manufactured with continuous automatic drying function and Electric heating method.

This machine is large in size with excellent multifunction, Features a high-efficiency and energy saving, its easy to operate and maintain.

Heating methods of the double cone are multifunctional as it features automatic and double mixers simultaneously

Ideal for ceramic drying with no direct fire hazard, Temperature is remote managed manually, easy to operate with no rotation or continuous control.

Manufactured with carbon steel and encloses the pressure in to thoroughly dry the grain, customizable size and standard temperature

Great advantage features Low consumption and a high productivity level. Energy-saving and produces low noise.

High-temperature air furnace, Steam heating in a well enclosed machine. Ideal for food processing in need of hot temperature.

How Vacuum Dryers Work

Vacuum dryers decrease the internal chamber pressure and enable rapid evaporation of liquids from materials at lower temperatures. The entire process occurs intermittently within a sealed container.

Specific Process:

Its vacuum pump reduces the pressure inside the drying chamber to 1–100 kPa (it is adjustable based on your process requirements). This lowers the water’s boiling point from 100°C to approximately 30–80°C. At this time, the heating system supplies heat to the material, making the moisture within to vaporize rapidly. The resulting vapor is continuously extracted by the vacuum pump, maintaining low humidity within the chamber.

Advantages of Vacuum Dryers

Lower energy consumption

Vacuum dryers achieve evaporation under vacuum conditions without a high-temperature heat source, and its overall energy consumption can be reduced by more than 20% compared with the traditional hot air drying method. This can significantly reduce your operating costs for large-scale or continuous production.

Shorter drying time

In a low-pressure environment, water vaporization’ rate significantly increases. Compared to conventional drying methods, the overall drying cycle is usually shortened by more than 30%. This can help you complete a batch more quickly and improve equipment utilization and production capacity.

Higher drying quality

Vacuum drying shows a low drying temperature and low oxygen content, which effectively prevents the decomposition of heat-sensitive components, product oxidation and discoloration, as well as the loss of active substances. The purity of the dried material can exceed 99.5% which decreases your material waste, particularly suitable for high-value materials.

Strong adaptability

Vacuum dryers can handle various forms of materials such as high-viscosity, paste-like, pasty, granular and powdered materials. And the vacuum dryers can also be customized according to your material characteristics to ensure the best heat transfer efficiency and material conveying method.

Durable

The equipment is constructed from 304 or 316L stainless steel, titanium, or special corrosion-resistant materials to deliver excellent corrosion resistance and wear resistance for you. The equipment can operate stably for a long time and is especially suitable for production scenarios containing acidic or alkaline solvents or with high purity requirements.

Vacuum Dryer Applications

The vacuum dryer is particularly suitable for processing heat-sensitive, easily oxidized, highly hygroscopic materials, as well as powders containing volatile solvents or toxic substances.

In the pharmaceutical industry, vacuum dryers are commonly used to dry medicinal powders, preventing thermal decomposition of active ingredients.

Some food industries use vacuum dryers to dry vitamins, probiotics, fruit and vegetable powders. The vacuum drying way can effectively minimize nutrient degradation while preserving color, flavor, and solubility.

The chemical industry frequently takes vacuum dryers to dry plastics or synthetic materials, which can avoid toxins or side effects from developing due to prolonged exposure to high temperatures.

Types of Vacuum Dryer

Vacuum Freeze Dryer

This machine can work at temperatures between -50°C and -80°C under high vacuum conditions of 1–10 Pa. Its moisture in materials directly sublimates from solid ice to vapor, completely bypassing the liquid phase. This process maximizes preservation of material structure and biological activity, achieving a biological activity retention rate exceeding 95%.

Post-freeze-dried materials exhibit intact pore structures and excellent rehydration properties to show good product stability for you. This makes them highly suitable for long-term storage and transportation of high-value biological products.

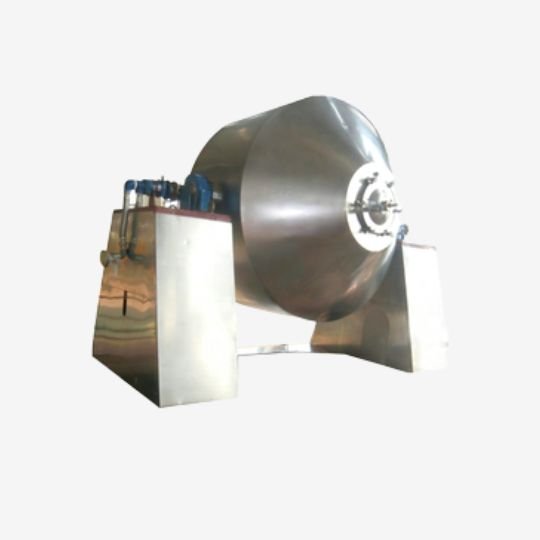

Vacuum Rake Dryer

The vacuum rake dryer features a horizontal cylinder with jacket heating. Special rake teeth mounted on the central drive shaft continuously propel materials axially through alternating forward and reverse rotation. At the same time, the rake scrapes the wall to renew the material surface to increase heat transfer efficiency.

Its rake structure can prevent caking and wall adhesion while improving drying uniformity.

If you need dry pasty, viscous, or easily caking materials, the vacuum rake dryer is an ideal solution for you.

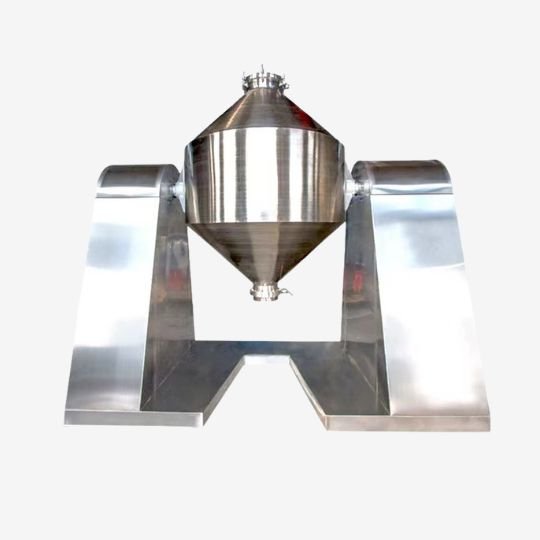

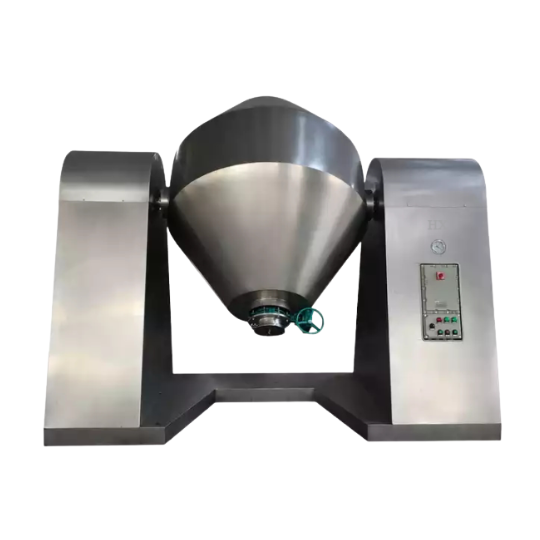

Double Cone Rotary Vacuum Dryer

The double cone rotary vacuum dryer consists of a double-cone rotating vessel composed of two conical ends and a central cylinder. It rotates at a low speed of 3–15 rpm under vacuum conditions and the material repeatedly tumbles along a “diamond trajectory” within the vessel to reach thorough contact with the heated walls, achieving uniform drying and mixing.

The equipment performs drying and mixing at the same time, which can enhance production efficiency. Its conical design enables automatic material sliding with a residual rate below 0.5%, which means it could minimize your raw material waste while ensuring uniform mixing.

Rotary Vacuum Dryer

The rotary vacuum dryer adopts a cylindrical rotating tank that can be fitted with baffles or agitator blades. This works at 5–30 rpm under vacuum conditions. The material continuously tumbles within the tank, fully contacting the heated walls and moisture rapidly evaporates and is evacuated via the vacuum system.

The vacuum rotary dryer offers you a large heat exchange surface area for rapid drying, particularly suitable for processing granular, powdered, or semi-flowable wet materials.

Conical Vacuum Dryer

This equipment features a vertical single-cone structure with a screw ribbon-screw combination agitator installed inside. It lifts material from the bottom to the top before returning it downward to create continuous circulation and tumbling action. This ensures thorough contact with the heating surface. Both the jacket and hollow agitator can simultaneously circulate heat transfer fluid, achieving efficient drying under a vacuum of -0.1 MPa.

Its vertical design minimizes footprint while delivering superior sealing performance. And it is particularly suitable for high-viscosity, high-solids-content materials prone to bridging. This machine is commonly employed in the finishing stages of pharmaceuticals, food additives, cosmetic ingredients, and high-end chemical products.

Parts of Vacuum Dryer

Vacuum chamber

The vacuum chamber is the core space of the entire drying process and typically made of 316L stainless steel or higher grade materials to deliver you excellent corrosion resistance and cleanliness. All sealed areas are equipped with FKM or SI sealing rings to ensure that the equipment can maintain a stable vacuum degree even under long-term negative pressure operation.

If you are handling active or high-value materials, it is optional to integrate with explosion-proof observation Windows or aseptic grade interfaces.

Vacuum Pump

Vacuum pumps establish and maintain the negative pressure environment required for drying processes while expelling water vapor or organic solvents generated during evaporation. They are critical components ensuring the energy efficiency and stability of the entire system.

Water Ring Vacuum Pump: This pump is composed of an impeller, pump body, and water circulation system. Its water-ring-formed sealing chamber exhibits insensitivity to water vapor and dust, suitable for materials with high moisture content and applications involving substantial solvent usage.

Rotary Vane Vacuum Pump: Their working chamber is formed by a rotor and vanes. It offers stable operation and rapid pumping speed, applied in requiring sustained deep vacuum, such as pharmaceutical precision drying.

Intermeshing Vacuum Pump: Their dual rotors operate without contact. Its dry design eliminates the need for oil seals and displays strong solvent resistance. This makes this pump suitable for high-purity materials or industries with stringent cleanliness requirements.

You can select the appropriate pump type based on material characteristics, target vacuum level, and solvent conditions.

Heating system

The heating device provides constant heat to the material, enabling materials to rapidly vaporize moisture in a low-pressure environment. Common types include jacket heating, tray heating, paddle heating, and electric heating, and so on.

The head system can be equipped with a PID temperature controller to keep the temperature within ±1℃. This will ensure that the activity retention rate of heat-sensitive materials exceeds 95% and avoid your production quality decline due to local overheating.

Condenser

The condenser rapidly cools the extracted steam and condenses it into liquid, achieving solvent recovery or safe discharge. For solvent-containing production lines, this is an important component for reducing operating costs and environmental emissions. It is usually of shell and tube or plate structure, with a solvent recovery rate of over 90%, and can handle most industrial solvents such as ethanol, acetone and toluene.

Stirring system

The stirring system enhances heat transfer efficiency though the material fully contacts the heating surface and it can avoid problems such as wall sticking, caking, and excessive local moisture content.

There are various types of stirring for you to choose such as rake tooth stirring, helical ribbon stirring, double cone flipping and atomizer.

Cleaning system

Most vacuum drying equipment can be integrated with a CIP online cleaning system (expandable SIP sterilization) to reduce the risk of materials cross-contamination and ensure compliance with GMP, HACCP and other standards. Meanwhile, the CIP system can shorten the cleaning time and significantly reduce your machine downtime.

Control system

The PLC control system is responsible for coordinating the operation of each component in a coordinated manner. It can achieve precise control parameters such as temperature, vacuum degree, and stirring speed with parameter fluctuation is ≤±1%. And it also supports automated production and data traceability.

If you produce multiple materials or switch frequently, CIP can significantly reduce the reliance on manual labor and compliance risks.

Safety device

The safety system prevents risks such as abnormal vacuum degree, over-temperature, overload, and excessive solvent concentration, which can protect the safety of equipment and personnel and meet industrial safety standards.

If your product is flammable and explosive, it can be equipped with an Ex control cabinet and explosion-proof actuating components to offer more safety for you production.

Consideration for Selecting Vacuum Dryer

Material Properties

Different materials have varying requirements for drying methods and equipment structure. So you must clearly understand the material properties before making a selection.

For example, if your material is sticky or paste-like, it is recommended choosing equipment with stirring or rake structures to prevent clumping or sticking to the walls during drying.

Vacuum Dryer Capacity

Please select an appropriate chamber volume and loading rate based on your production capacity requirements.

Laboratory R&D applications may opt for 1-20L models, while large-scale drying operations should consider industrial-grade vacuum dryers with larger capacities.

Drying Efficiency

Drying efficiency depends on heat transfer methods, vacuum level, agitation techniques, and material contact surface area.

For accelerated drying, you can pair vacuum dryers with multi-zone heating, enhanced agitation, deep vacuum pumps, or optimized condensation systems to increase the drying efficiency.

Additional Features

Prioritize equipment equipped with CIP (Clean-in-Place) systems, PLC + touchscreen HMI control systems, safety interlocks, and alarm systems to enhance your operational convenience and safety.

Cost

Beyond the purchase price, operational costs such as energy consumption and maintenance expenses are also important for you.

Vacuum dryers efficiently complete material drying under low-temperature, low-oxygen conditions, particularly suitable for processing heat-sensitive, high-viscosity, solvent-containing, and high-value materials. FANQUN can match the appropriate drying type and configuration based on your process parameters, production capacity planning, and material characteristics. Contact us to obtain your customized vacuum drying solution.

The vacuum drying cycle is not fixed and primarily depends on material properties, initial moisture content, target moisture content, heating method, and achievable vacuum level. Generally, a complete drying cycle may range from several hours to over 24 hours.

Yes. By installing a condenser (commonly referred to as a vapor condenser) between the vacuum dryer and the vacuum pump, the evaporated solvent can be cooled and condensed back into liquid form. This configuration reduces solvent loss, significantly lowers waste liquid treatment costs and minimizes the risk of corrosion to the vacuum pump.

Yes. We offer comprehensive services from installation and commissioning to process optimization and operational training. Training covers equipment operation, safety protocols, cleaning procedures, daily inspections, and more, ensuring your team can quickly master and reliably operate the equipment.