FANQUN Pressure Spray Dryer

FANQUN’s pressure spray dryer mainly relies on a high-pressure pump and hot air system to convert liquids into fine powders, achieving high drying speed and high recovery rate. Please feel free to contact us for purchasing!

- The pressure spray dryer is made of 316L stainless steel to prevent pollution and sticking issues;

- Extremely high drying speed to preserve active and heat-sensitive ingredients of raw materials;

- High production capacity around 50L/h to 5,000L/h to handle different types of materials;

- Provide high recovery rate within a range of 96%- 98% or higher;

- FANQUN features advanced production technology and has accumulated more than 30 national patents;

- All of FANQUN’s pressure spray dryers obtain international certifications like ISO 9001.

GYPG Series Pressure Spray Dryer

GYPG series broad-spectrum high pressure spray dryer(“95” scientific research project in China).The machine adopts full seal form.All parts are made of stainless steel.It is equipped with three grades of purifying apparatus.The filtered air reaches the requirement of one hundred thousand grades.Automatic washing device is installed at the place where raw material passes.It belongs to vertical falling cocurrent flow type pressure atomizing dryer.Its wall of tower has no adhesive phenomenon.It has wide adaptability.Through adjusting pressure of high pressure pump for raw material supplying,the atomizing pressure can reach 1-20 Mpa, It can meet the requirement for drying immersed ointment of traditional Chinese medicine containing 20-30% of solid content.The average size of finished product will be 40-120 mesh.Because its size is large,the granulating procedure can save and the one-step drying can be realized.Meanwhile it can also return the powder to granulate again in order to increase the size of granule and decrease the ratio of powder in finished product and make the granule uniform.The bulk density of finished product is small.Its dispersivity,fluidity and solu-bility are good.It is suitable for making drinking agent,powder agent or capsule raw material medicine of traditional Chinese medicines or compound preparations.

Principle of GYPG Series Pressure Spray Dryer

The broad-spectrum high-pressure spray dryer is an application of pressure atomizing drying technology in special raw material. That is to say,it is a dry appa-ratus to send raw material to the nozzle through high-pressure pump and make raw material distributing in fog that contacts with parllel stream hot air fully.In this way the dry is finished momentarily and the finished product of powder or granule is formed.

The differences between broad-spectrum high-pressure spray dryer and ordinary pressure dryer are as follows:it adopts primary,middle and high effect three-grade filter,low temperature of hot air and a big amount of hot air,there for it can prevent the effective ingredient of traditional Chinese medicines from volatilizing and decomposing.The raw material to be dried will be solidified momentarily and does not attach to the wall It integrates low,middle and high pressure atomizing in one body and solves technical key of tower body and pipes cleaning.

The equipment had passed state level check and accept and won good appraising from specialists.

Features

of GYPG Series Pressure Spray Dryer

- Tower body is equipped with automatic vibration and beating device;

- Tower body and pipe line have cleaning hole and sewage discharge hole that can open quick;

- Thermostat feeding tank;

- Raw materia filter;

- Accompanied parts of high pressure washing tower manually;

- The parts that can contact with raw material are made of stainless steel fully;

- The collecting of raw material adopt two-grade cyclone duster,(standard clone duster)or one-grade cyclone duster and one- grade damp duster;

- The temperature of inlet air can be controlled automatically;

High quality and high pressure mini spray dry machine that ensures, Multifunctional and easy to operate.

Portable with Great thermal efficiency and has a low consumption rate. Core component with pump and has wide application for various processes.

Steam heat method that ensures the chemicals stays within and has energy-saving control.

Application widely for food processing, drying milk into power, energy sufficient and equipped with heat dissipating pressure.

An Ideal for food granulation using a pressure spray dryer, has multiple heating methods including electric heating or gas, steam and liquefied gas.

Chemical mixture with no close contact exposure improves pesticides effectiveness. Easy to operate and navigate.

Adjustable soap powder spray with Multifunctional control, Atomizer spray in centrifugal and is electric heating method.

Centrifugal and has wide application for chemicals, plastics and food. Heating methods provided are electric and steam heating. Energy sufficient with temperature control.

- Our Factory

- Technical Parameters

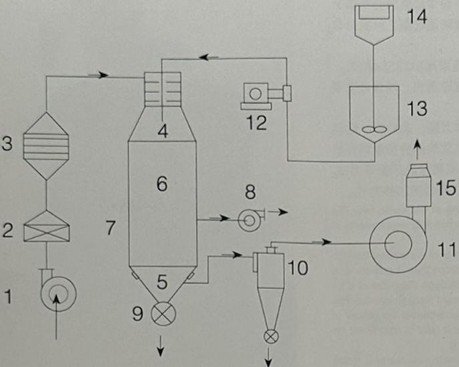

- Technological Process

| Treated amount of raw material liquid(kg/h) | 31.57-47 | 63.14-94 | 126.28-188 | 189.42-282 | 252.56-376 | 378.84-564 | Depends on actual situation |

| Output of finished prcduct(kg/h) | 6.85-22 | 13.70-44 | 27.40-88 | 41.1-132 | 54.8-176 | 82.2-264 | Depends on actual situation |

| Solid content of damp raw | 20-45 | ||||||

| Ratio of moisture of product | 3-5 | ||||||

| Electric power(kw) | 50 | 82 | 117 | 150 | 238 | 320 | Depends on actual situation |

| Heating source | Steam plus electricity | ||||||

| Collecting way of product and Its efficiency | Two-grade cyclone duster or one-grade cyclone duster and one-grade damp duster | ||||||

| Automatic control | Meters and instrument;Indicator of temperature of hot air and humidity of air exhaust | ||||||

| Temperature of air in℃ | 150-200 | ||||||

| Temperature of air out℃ | 80-100 | ||||||

| (LxW×H)(mm) Overal dimensions | 6145×1500×9300 | 6875×1700×11300 | 7765×1980×14500 | 8785×2650×17000 | 9700×2800×18700 | 10900×3000×21000 | Depends on actual situation |

- Blower

- Air filter

- Heater

- Spray gun

- Vibrating device

- Drying chamber

- Jacket of cool air

- Fan of cool air

- Valve of material discharging

- Cyclone

- Draught fan

- High-pressure pump

- Stirring tank

- Filter of raw material

- Muffler/silencer

What is Pressure Spray Dryer

A pressure spray dryer relies on a pump to offer high pressure, atomizing liquid materials into fine droplets, which can be dried by hot air. The hot air offers high speed to evaporate the droplets, thereby improving drying efficiency. Due to its high drying speed, stable product quality, and other unique advantages, the pressure spray dryer is widely used for various industries.

How Does the Pressure Spray Dryer Work

Learning how a pressure spray dryer works can help you better know its features and advantages, thereby making wise purchase decisions. Its working principle can be typically divided into the following three steps:

- Step 1: Before the formal drying process, the liquid materials are firstly pressurized by a high-pressure pump to 1- 10 MPa. Then the liquids through a nozzle to be atomized into extremely fine droplets. The atomization level is directly connected to the final product features, such as particle size, shapes, and more.

- Step 2: The droplets then are evenly introduced into a large drying tower, which has been preheated. The droplets contact with hot air in the drying tower and its water content evaporates rapidly within a few seconds to a few percent. This high-speed drying process efficiently preserves active and heat-sensitive components of raw materials.

- Step 3: After the drying process, most of the dried powder settles at the bottom of the drying tower. While a small amount of extremely fine powder is carried away by the separation system. This system offers high efficiency to collect final products and remove the exhaust gas, achieving a high recovery rate that can reach 96%- 98% or higher.

Key Components of Pressure Spray Dryer

- High-Pressure Pump: The high-pressure pump of a pressure spray dryer determines atomization effects. It is typically made of stainless steel or high-strength alloys to meet different material demands. The high-pressure pump is also equipped with a reliable sealing system to ensure stable operation. Based on the properties of different raw materials, you can choose different types of pumps, including piston pump, screw pump, plunger pump, and more.

- Atomization System: The nozzle is the key component of the atomization system of a pressure spray dryer. It directly decides the particle size, product shape, and drying efficiency. In general, the smaller the orifice of nozzles, the finer the spraying droplets. You can choose a suitable nozzle for your machine based on the actual requirements. The nozzle is easy to wear so it can be produced by high-strength materials to ensure a long service life.

- Drying Tower: High-quality drying towers are typically made of 316L stainless steel to ensure smooth surface thereby preventing material adhesion to the interior wall. The height and diameter of a drying tower is connected to the drying time and final capacity. It must be matched with the atomization angle, spray pattern trajectory, and hot air distributor.

- Hot Air System: The hot air system of the pressure spray dryer is used to provide a clean and stable drying medium for droplets. It offers multiple types of heat sources, such as steam, natural gas, or electric heating. The temperature of the hot air should also be controlled precisely to ensure high product quality.

- Separation System: The separation system consists of a cyclone separator and a baghouse dust collector to collect products and remove exhaust gases. As the primary separation, the cyclone separator features simple structure and consumes low energy. It can recover most of the final products. While the baghouse dust collector is used to capture extremely fine particles, achieving high recovery rates.

Advantages of Pressure Spray Dryer

Stability and Reliability

The structure of a pressure spray dryer is enclosed to ensure stable operation, meeting the demands of high cleanliness and safety. Key components of the machine are typically made of food/medical-grade stainless steel with high reliability. This not only prevents pollution and residue issues, but also reduces material adhesion to decrease maintenance rates. Once the machine is damaged, it is easy to repair or replace the damaged components quickly due to its simple structure, reducing downtime production loss.

Superior Product Quality

- Consistent Particle Size: The pressure spray dryer offers flexible and precise control to the particle size by adjusting the pump pressure and changing different nozzles. The finished products produced by the pressure spray dryer also feature high consistency to achieve batch production.

- Excellent Flowability and Solubility: Due to the surface tension, droplets will form ball-shaped particles during the drying process, which offers excellent flowability for the products. For instant products, this type of loose particle can accelerate the dissolution process to enhance product grade.

- Preserve Active Ingredients: The pressure spray dryer is also suitable for heat-sensitive materials to preserve their active components by the high-speed drying speed. This is especially important for the food industry to preserve natural flavor, color, and nutritional value of raw materials.

High Efficiency

The pressure spray dryer offers high drying capacity within the range of 50L/h to 5,000L/h, meeting large-scale project demands. Compared to traditional drying methods, this machine achieves continuous operation, increasing the capacity and efficiency. The pressure spray dryer also supports a PLC control system to enhance its automation level. This not only reduces your labor costs, but also ensures highly consistent finished products. In addition, the machine also offers high pressure to handle high-viscosity materials with high evaporation efficiency.

Economic Advantage

The pressure spray dryer features rust structure to extend its service life, reducing your maintenance costs. It is also equipped with a high-efficiency material collection system to improve the recovery rate, reducing product loss and enhancing the economic benefits. For large-scale projects or high-viscosity materials, the pressure spray dryer also offers excellent thermal efficiency to save energy consumption.

Pressure Spray Dryer Applications

Food Industry

In the food industry including dairy products, coffee powder, seasonings, and more, all can be produced by a pressure spray dryer. This machine is made of food-grade stainless steel to meet HACCP demands. It also supports controlling the particle size to enhance solubility of the finished products. The rapid drying process of the pressure spray dryer also reduces nutrient loss to ensure high product quality for your project.

Chemical Industry

The pressure spray dryer is also widely used in the chemical and new material industry, such as catalysts, battery materials, pigments, and more. It ensures concentrated particle size distribution to enhance the consistency of chemical materials. Even for the high-viscosity material, this machine still offers high efficiency to handle it by high pressure. In addition, for materials that contain organic solvents or harmful components, the pressure spray dryer can collect the volatile gases and waste liquids to prevent safety risks.

Pharmaceutical Industry

In general, the pharmaceutical industry has strict demands on the drying process due to its unstable components. The pressure spray dryer features a function to dry instantly, and tries the best to preserve heat-sensitive or active ingredients of the raw materials. It also offers excellent particle flowability, making the machine suitable for the formulation processes. Due to the unique advantages, the pressure spray dryer is typically used to handle enzyme preparations, medicine extracts, and peptides of the pharmaceutical industry.

Agriculture Industry

Due to the controllable particle size of the pressure spray dryer, it is widely used to produce soluble pesticide or fertiliser granules. These products achieve a slow release effect to enhance pesticide efficacy and improve agricultural yields. After the drying process, the agricultural materials also become more easy to transport, which can decrease your entire costs.

As a professional pressure spray dryer supplier, FANQUN features mature production lines and advanced technologies to ensure high product quality. We have obtained more than 30 national patents and our machines are exported to more than 50 countries. If you have any questions about the pressure spray dryer, please feel free to contact us for reliable solutions.

A pressure spray dryer mainly relies on high-pressure pump and nozzle to atomize liquids, generating uniform powders and suitable for high-viscosity materials. Its structure is more simple than the centrifugal type, making it easy to maintain. While the centrifugal spray dryer uses a high-speed rotating disc to generate centrifugal power. It is suitable to handle a large amount of flow, and is difficult to be clogged.

The machine is made of stainless steel to reduce sticking materials. Its large diameter also ensures sufficient residence time for droplets to dry, preventing the semi-dry material contact with the walls. If you have requirements, the interior walls of the drying tower can be polished or added coatings to prevent sticking issues.

The nozzle clogging issues are typically caused by the solid content deposits of raw materials. When you select the pressure spray dryer, you can purchase filter components and clog-resistant nozzles to reduce the failures. During the drying process, you should maintain continuous circulation and agitation for the liquids. And cleanliness after using is also important.